New Garnet 70

OVER-STANDARD SOLUTIONS IN SERIES OF 70

Today's urban culture and building technology are shaping and changing in brand new dimensions. Cities are filled with the differentiating silhouettes of this change. Our new living spaces emphasize the principles of aesthetics, insulation, comfort and energy efficiency. By closely following this change, we meet the needs of differentiated building technologies with a new series. New Garnet, which interprets the 70% series standards with a different understanding of aesthetics and insulation, and New Garnet Strong with 3 gaskets continue to be the new choice of modern buildings.

3 contalı sistem

70'LİK SERİDE YENİ DÖNEM

EXPERIENCE, TECHNOLOGY AND DESIGN COME TOGETHER IN NEW GARNET 70

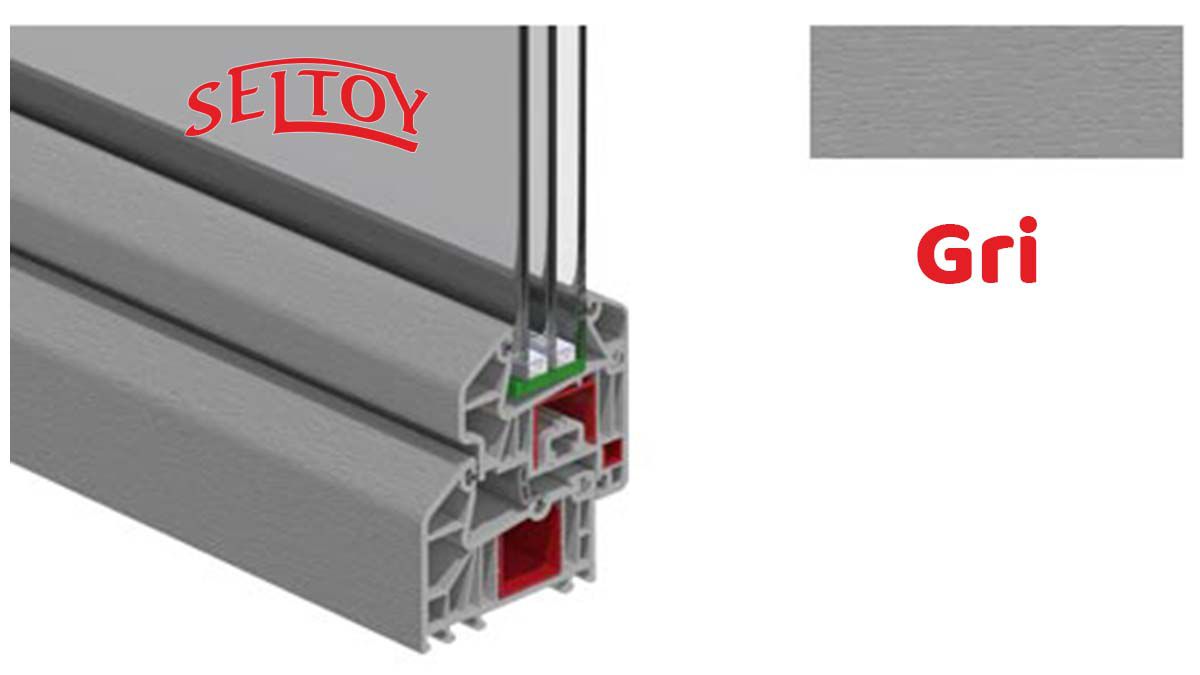

Designed to take the understanding of insulation and aesthetics in window standards to a new dimension, the New Garnet and New Garnet Strong Series increase the comfort of your living spaces with excellent heat and sound insulation. New Garnet with 70 mm width and 5-chambered design and Garnet Strong with 3 gaskets are the choice of the new generation architecture in search of a different aesthetic. New Garnet and New Garnet Strong meet the expectations of new trends in decoration with 22 different color options and start a new era in modern buildings by providing superior heat and sound insulation within the 70 series. By offering windows in different colors inside and outside, it develops alternatives that are compatible with your decoration and wall color as well as the exterior surface of your buildings.

| Profile Width (mm) | Meat | Gasket Number | Air Permeability Class | Water Tightness Class |

|---|---|---|---|---|

| 70 | B Sınıfı | 2-3 | 4 | 9A |

| Wind Load Strength Class | Number of Chambers (Name) | Sound Isolation (db) | Profile Thermal Insulation (W/m2°K) | Window Thermal Insulation (W/m2°K) |

|---|---|---|---|---|

| C3 | 5 | 40 | 1,12 | 1,05 |

New Garnet 70

System

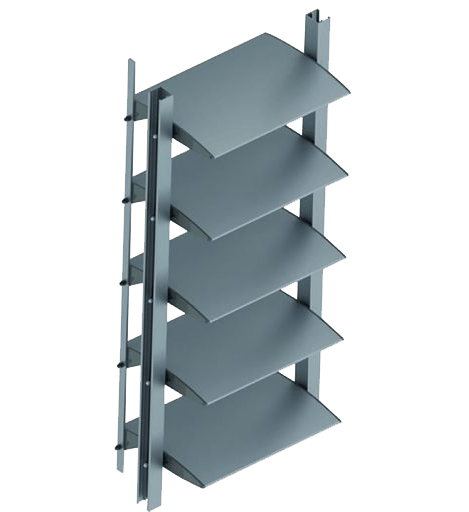

- In the Garnet System, all main profiles of which have 70 mm width and B class wall thickness, the new Garnet Strong 3-gasket design provides maximum insulation values in the 70 series.

- While the system has 4 different slat types that increase the interior surface width, it also offers 4 different decorative slat alternatives.

- Thanks to the detail and auxiliary profiles designed in accordance with the main profiles, it can easily solve all architectural details.

- Thanks to the lath profiles of the system, glass applications up to 40 mm can be made.

- The New Garnet and New Garnet Strong series offer options that will meet the decorative expectations of your home and add value with 22 different laminated color alternatives.

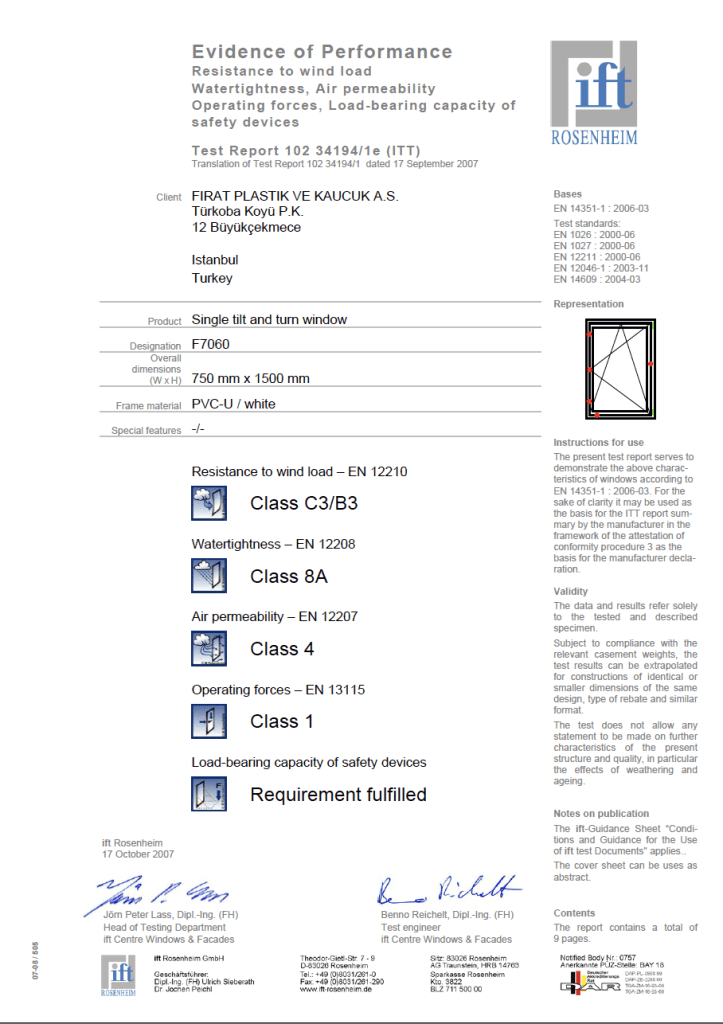

Wind Load Resistance

- Garnet sistemi 1800 Pa emniyet testine ve 600 Pa (110 km/h) su sızdırmazlık dayanımı testine göre tasarlanmış ve bu testlerden başarıyla geçmiştir.

- The New Garnet Strong Series with 3 seals is the perfect solution to provide strength in high wind load structures.

- While developing the garnet system, the maximum wind load values that the structures can be exposed to were taken into consideration, and the structure of the support sheets and their positions in the profile were designed to obtain maximum efficiency.

- Thanks to the detail and grillage profiles that offer solutions to meet architectural expectations, the system easily provides the necessary strength values and closure of large openings in buildings.

Water and Air Tightness

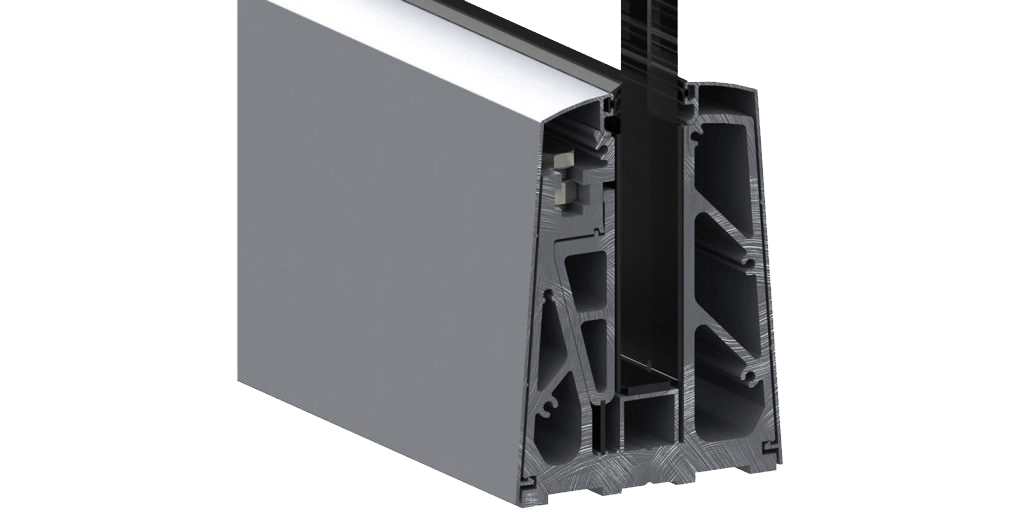

- The New Garnet Strong Series is designed with 3 seals to keep air and water permeability to the lowest levels.

- In addition to the standard inner and outer gasket, the prevention of air passage from the external environment to the internal environment, which is required for energy conservation, is provided with a center gasket.

- The Garnet System provides high resistance against rain even under high wind loads thanks to the water discharge angle and sets developed for faster and more comfortable water discharge.

- Tests under 600 Pa (110 km/h) wind load showed no water leakage into the interior environment.

Thermal insulation

- While designing the New Garnet and New Garnet Strong Series, it was aimed to keep the heat transmission coefficient value, which is the most important point for energy conservation in PVC window systems, at the lowest value.

- Sistemin profil genişlikleri, odacık sayıları ve odacık genişlikleri ısı ve ses yalıtımının en üst seviyelerde tutulabilmesi için geliştirilmiştir.

- With the 3rd center seal system, the best insulation values that can be achieved in a 70 pvc window system have been achieved.

- All profiles of the garnet system have a 5-chamber structure and since the chamber widths are large, the heat transfer coefficient values are ensured to be at low levels.

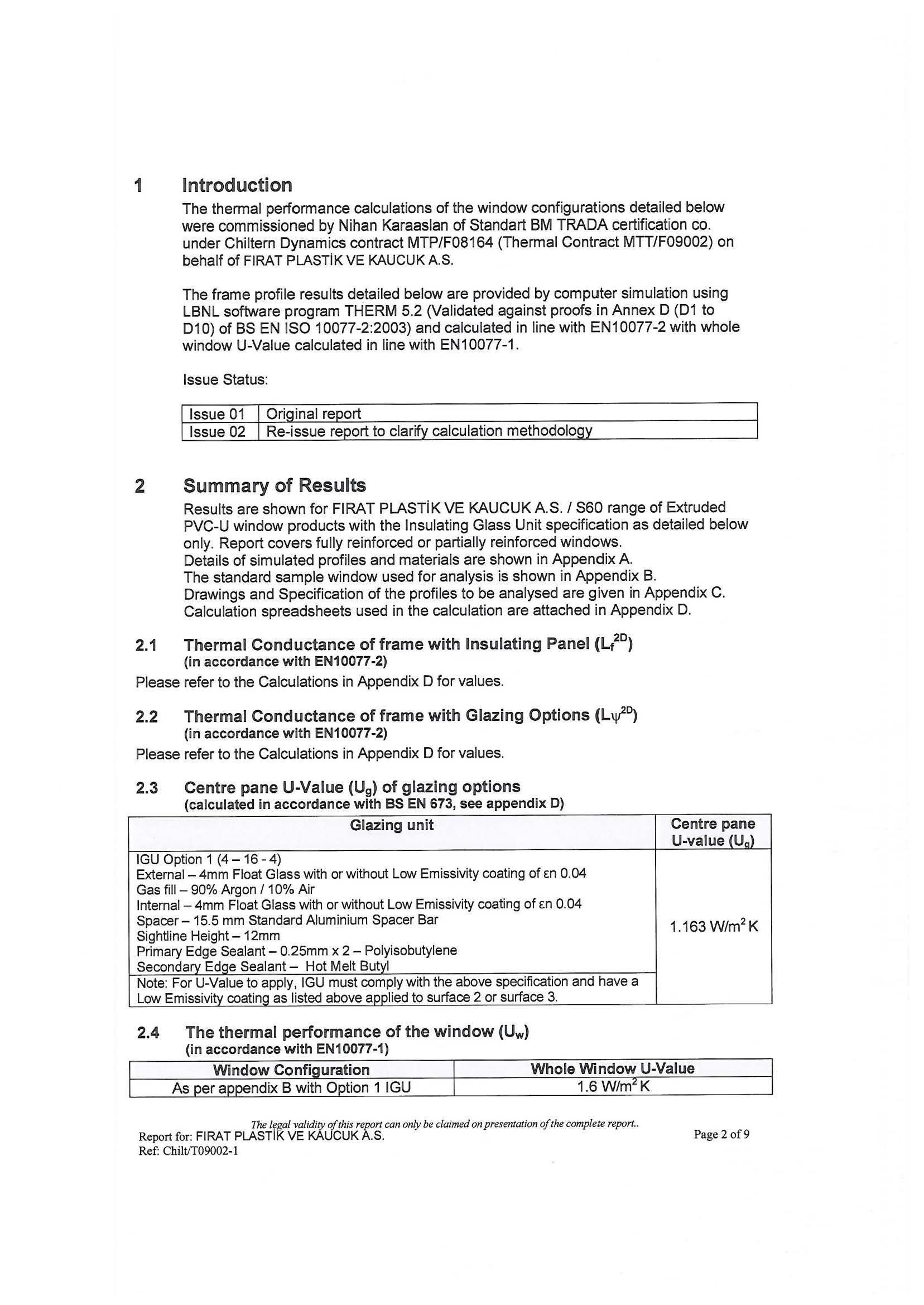

- In accordance with TS EN ISO 10077-2 standard, Ug : 0,7 W/m2K, Uw : 1,05 W/m2K and Uf: 1,2 W/m2K values were achieved.

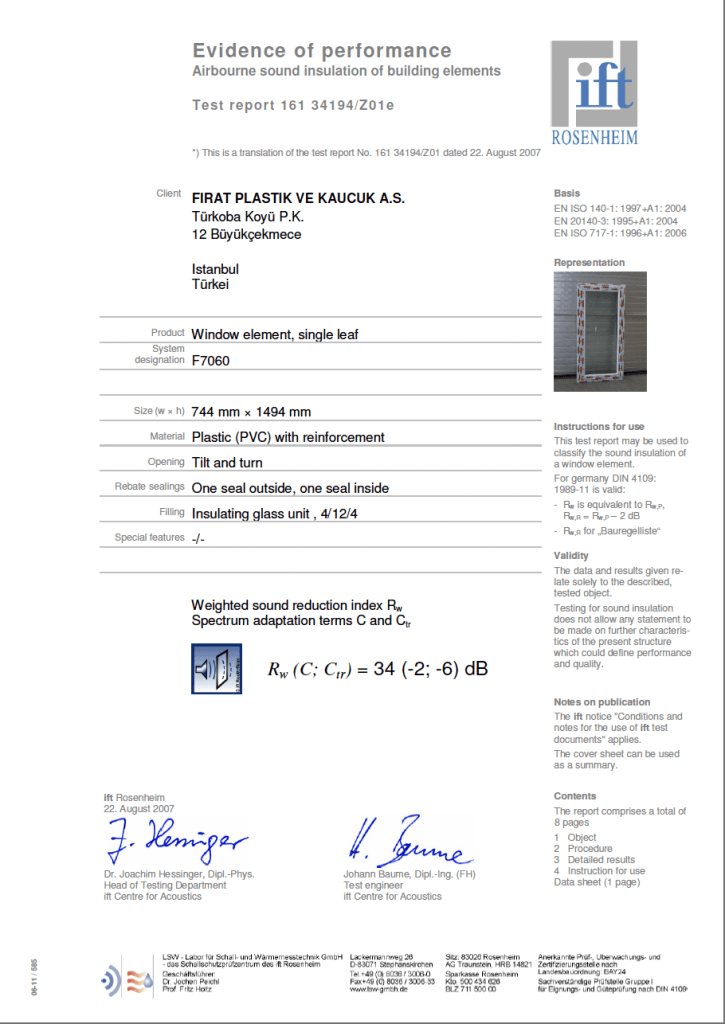

Sound insulation

- One of the most important quality criteria of window systems is sound insulation. The high sound level of around 70 dB in buildings close to airports, railways or major highways is reduced to below 30 dB with the New Garnet and New Garnet Strong systems, which is the sound level at which a child can sleep comfortably.

- New Garnet and New Garnet Strong series provide sound insulation up to 40 dB. Thus, it is possible to create a sound environment at a quality living level even in the noisiest environments.

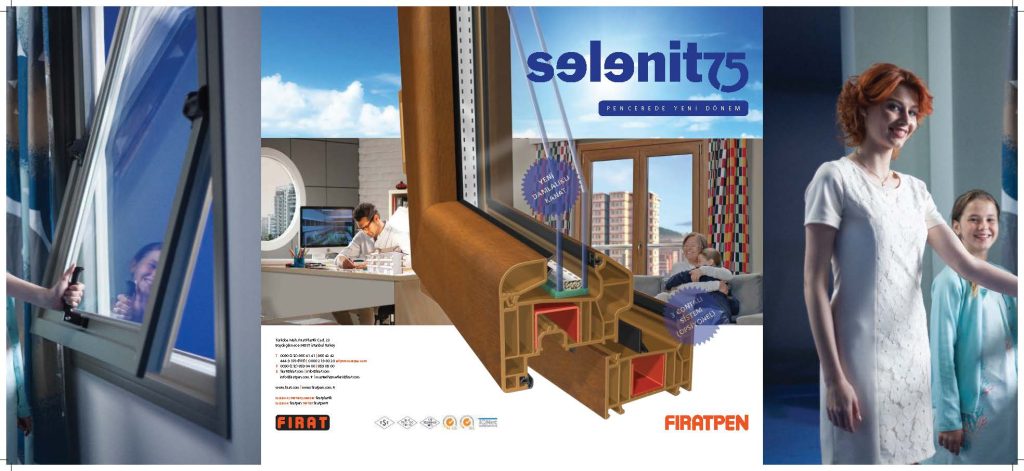

Estetik, güç ve performans kriterleri en üst seviyede tasarlanan Selenit modern yapıların yeni penceresi. Değişen yaşam kültürü ve mekan anlayışı gözetilerek “zamanın ruhu”na uygun çözüm arayanlar için geliştirildi. Selenit tüm teknik ve görsel detaylara cevap veren 75 mm profil genişliği, 6 odacıklı tasarımı ve opsiyonel 3. conta seçeneği ile bir sistem bütünlüğü sunuyor ve bu parametreler ile en üst düzey performans değerlerini yakalıyor.

Hesaplamalar TS EN ISO 10077-2 standardına göre 1,23×1,43m ölçülerinde pencere için 0,6 W/m2K ısı iletim kat sayısına sahip cam ünitesi kullanılarak yapılmıştır.

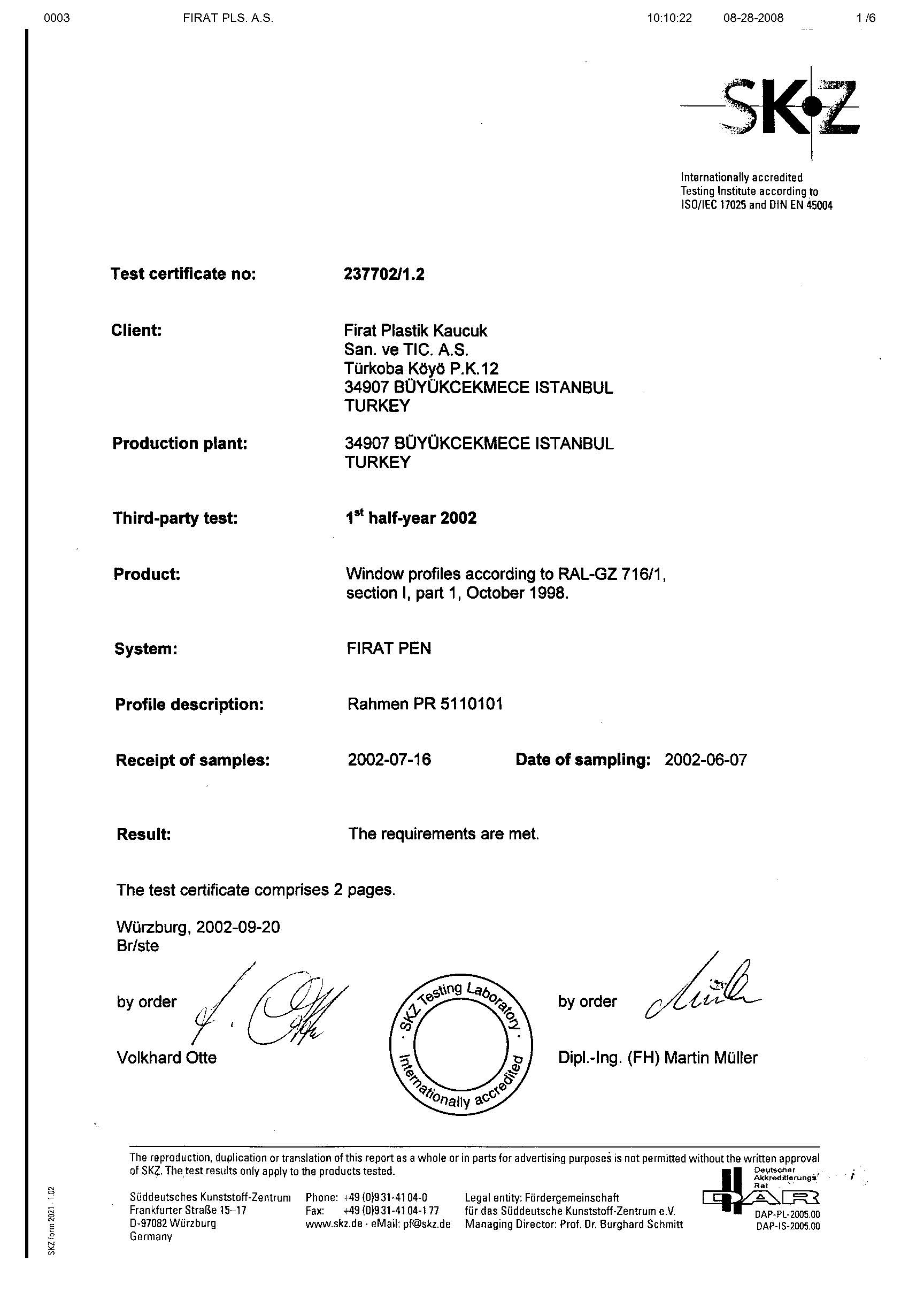

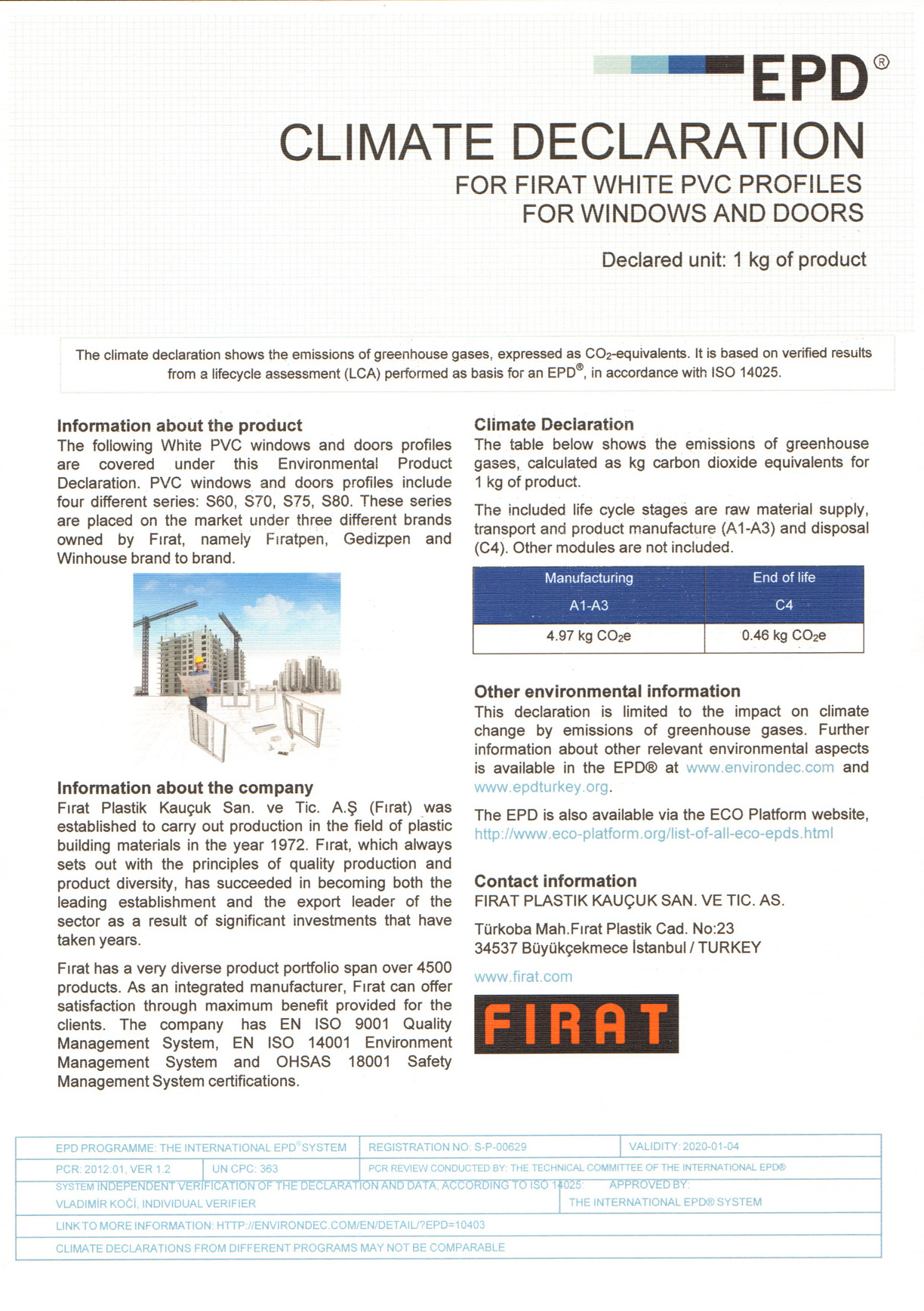

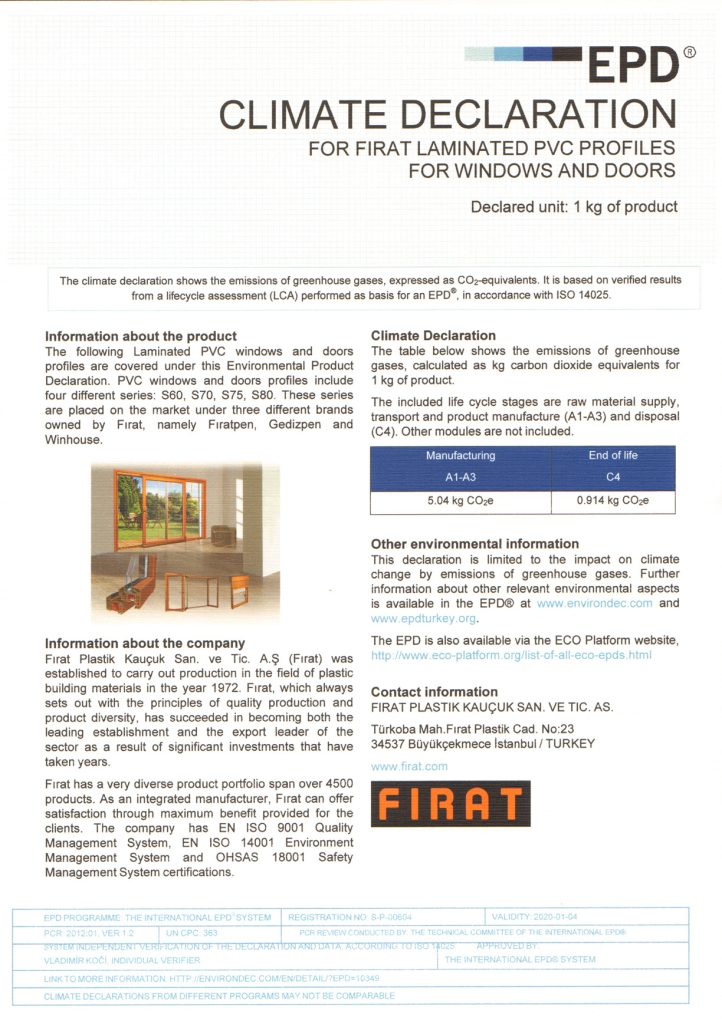

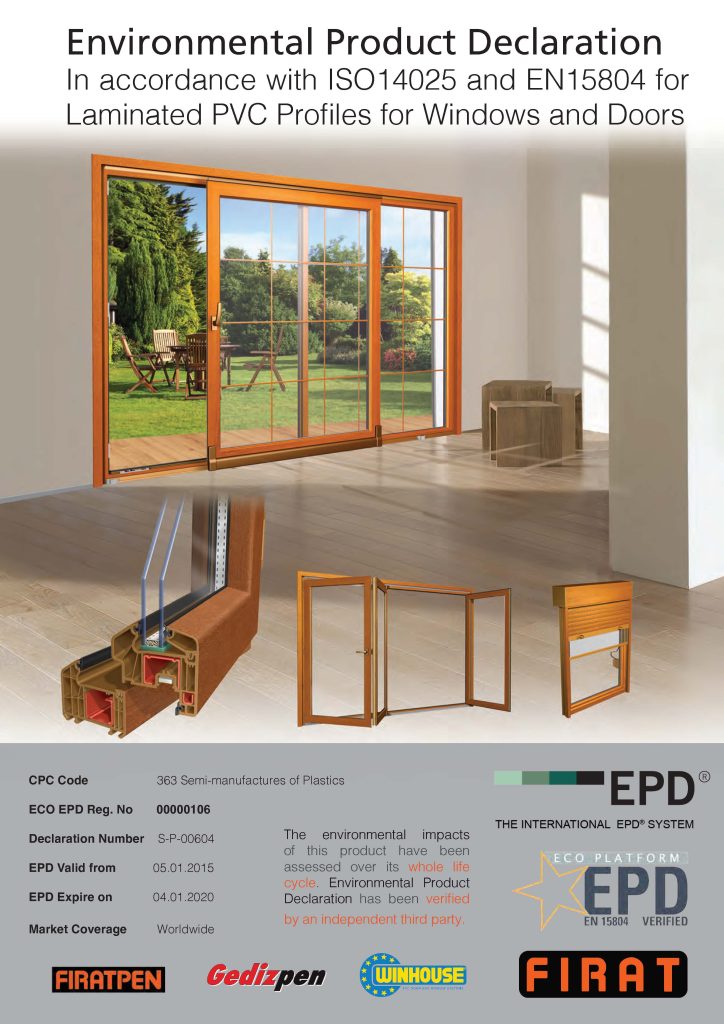

Quality Certificates & Technical Documents

- Quality Certificates

- Technical Brochures

- Test Reports

- System Documentation

- Environmental Product Certificates

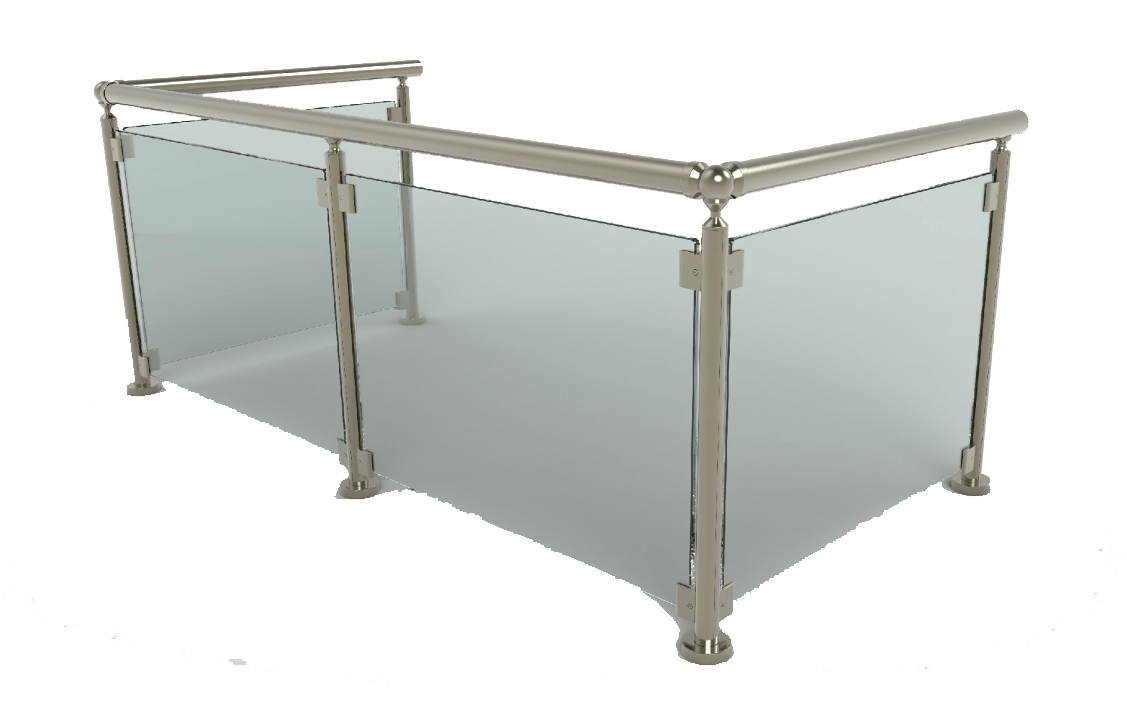

Window and Door Details

- Detail PVC Profiles

- Laminated PVC Profiles

- Components of PVC Door and Window Systems

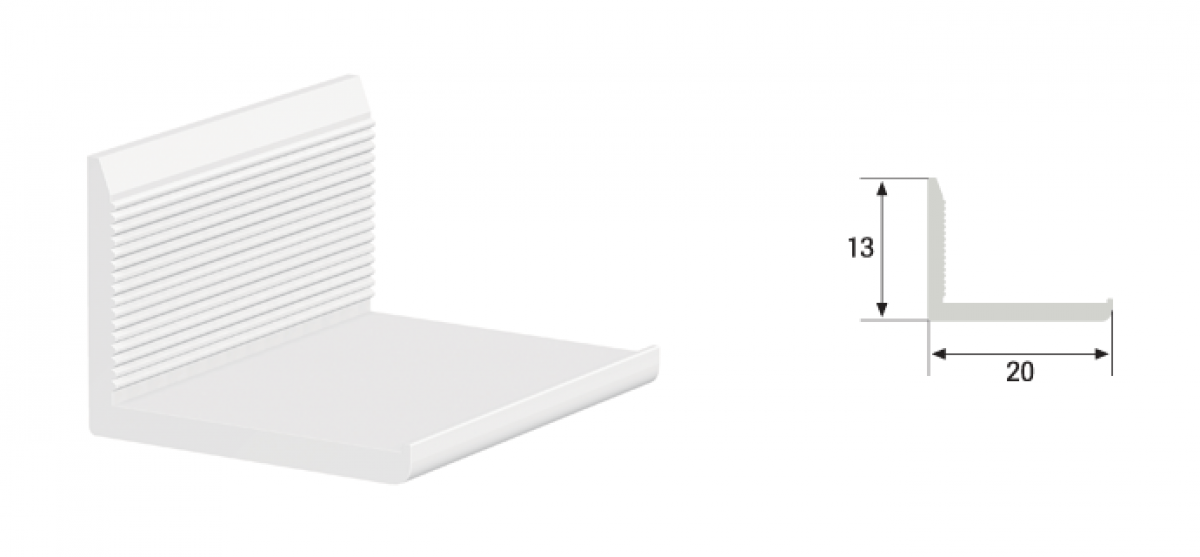

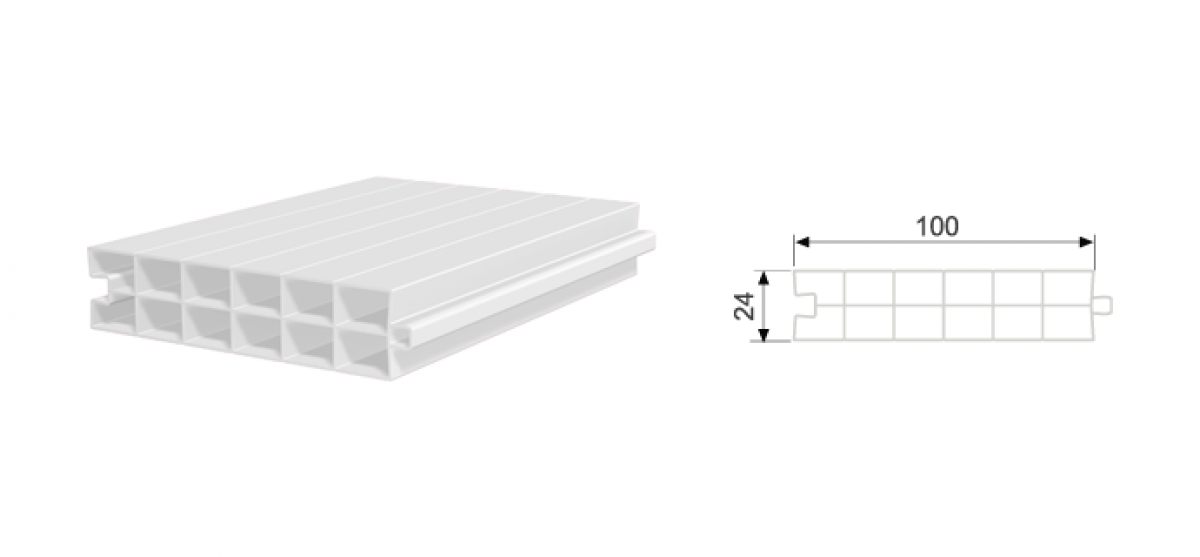

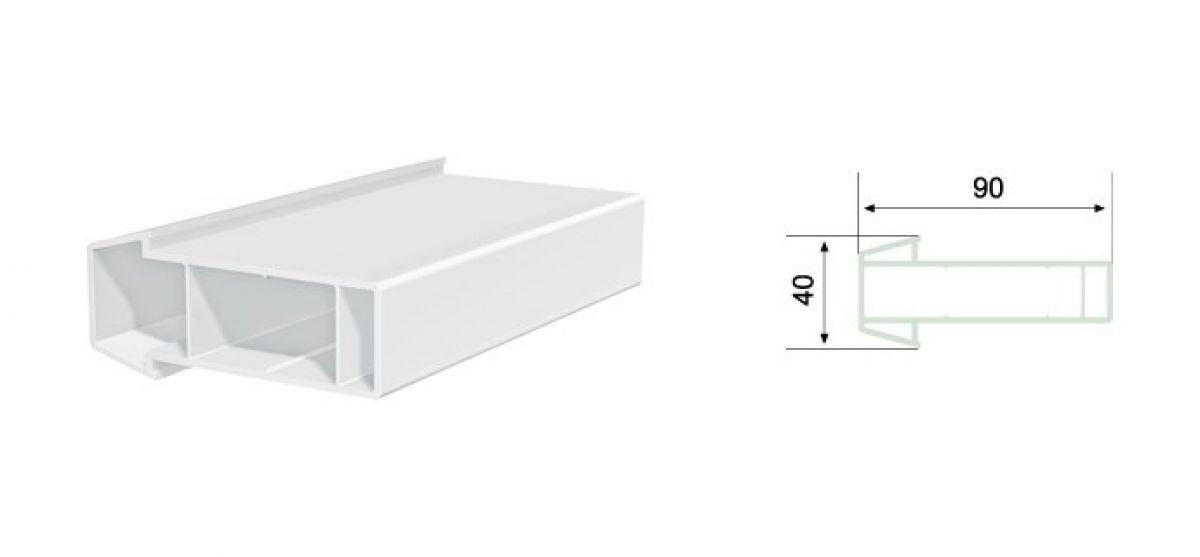

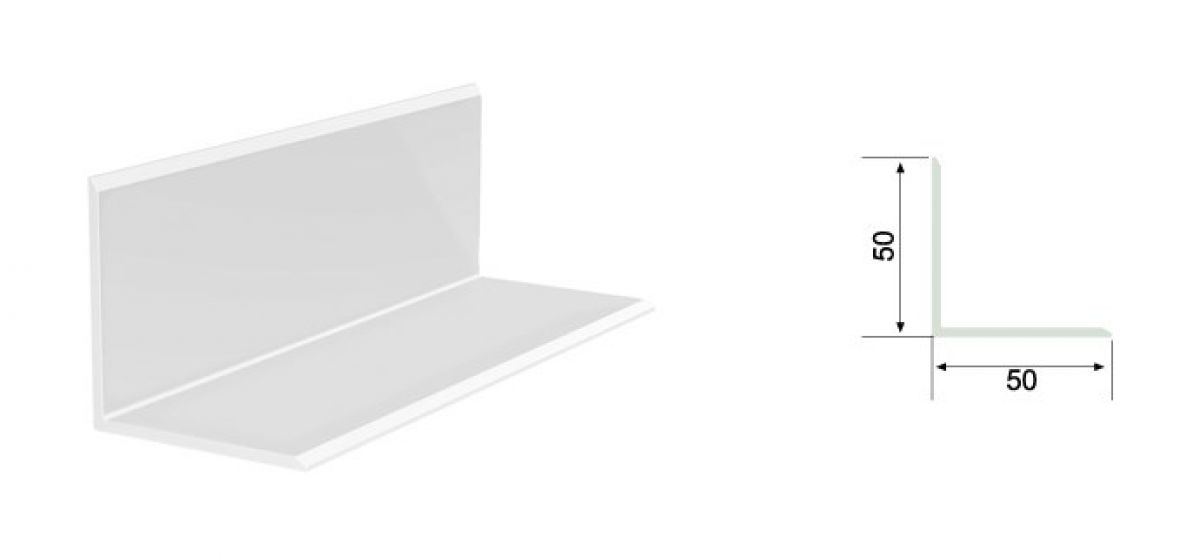

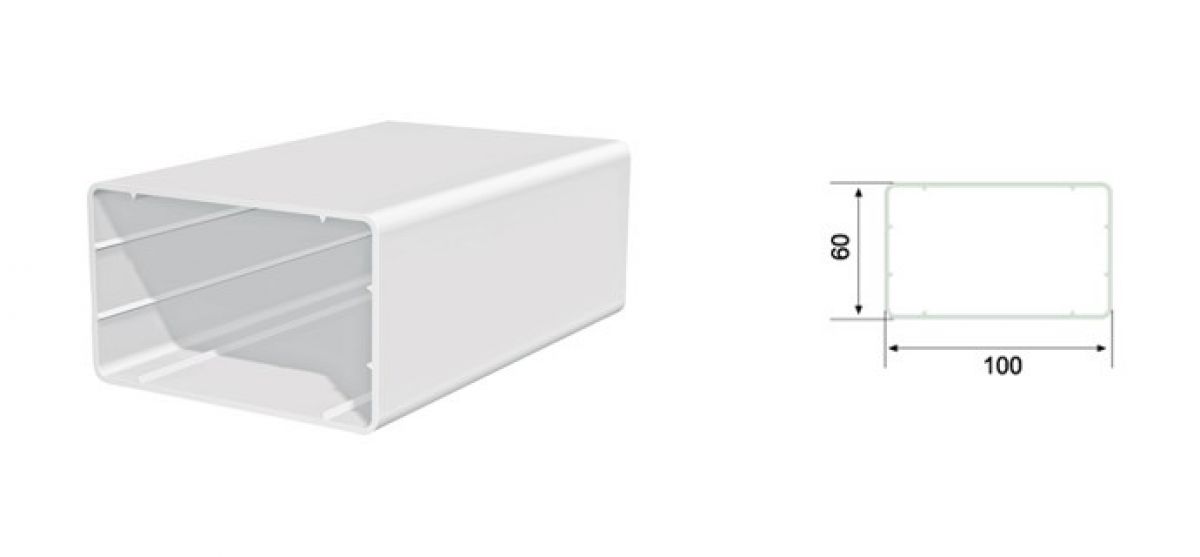

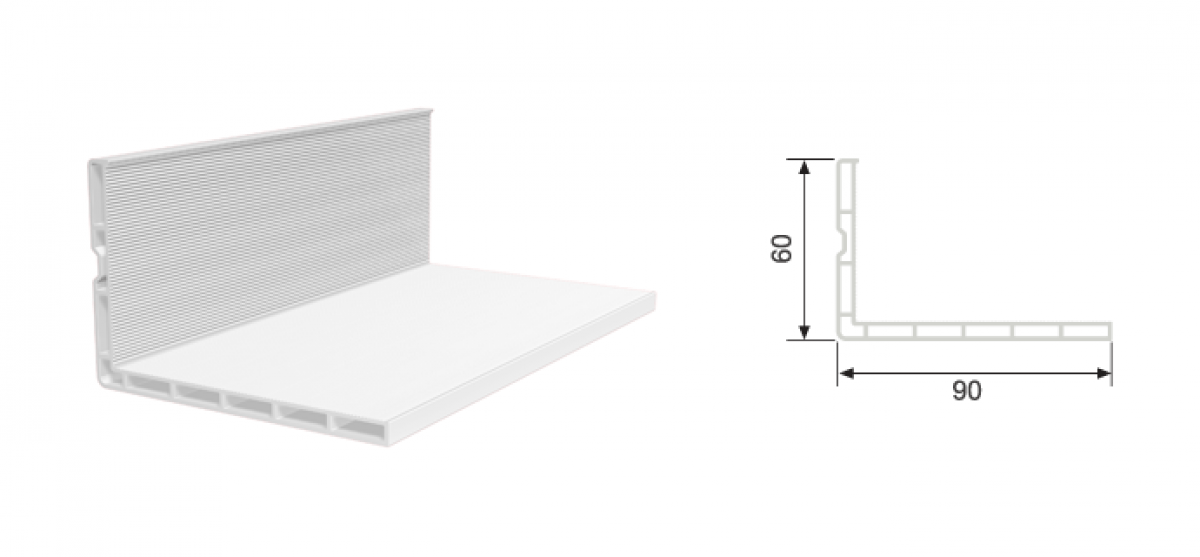

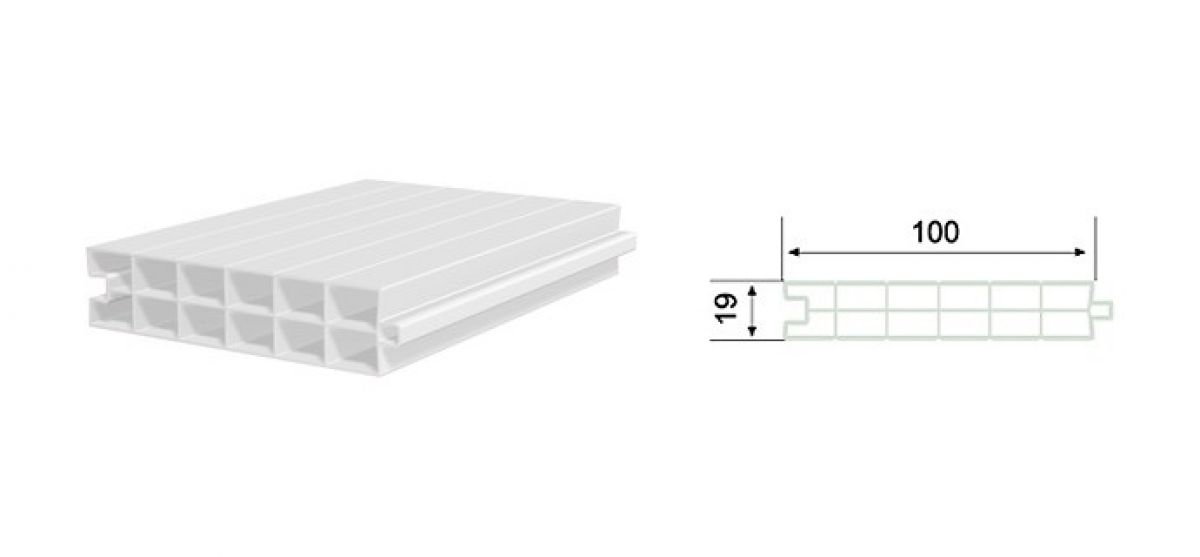

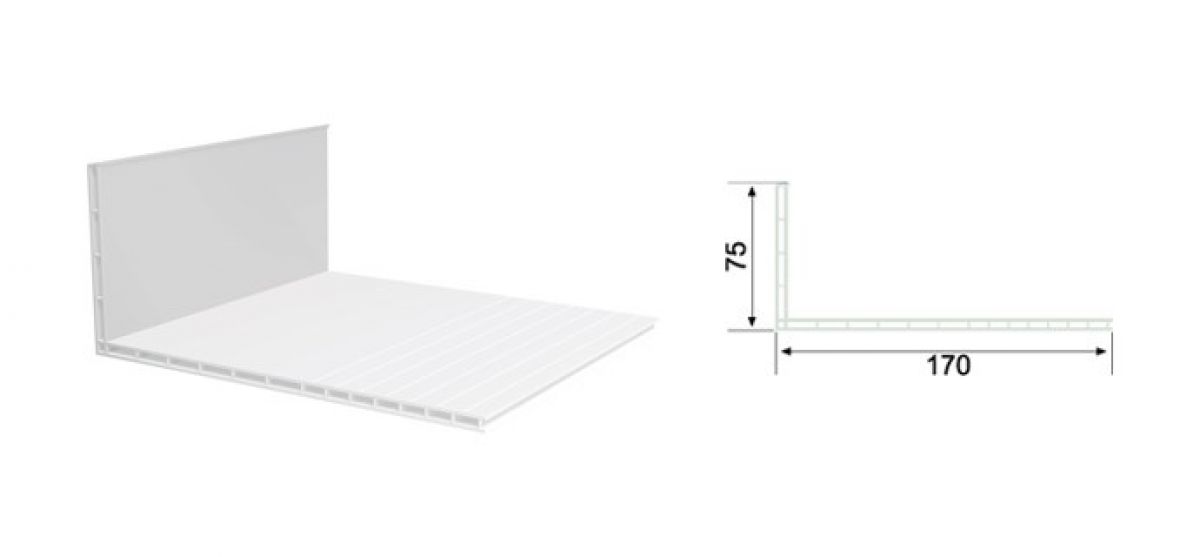

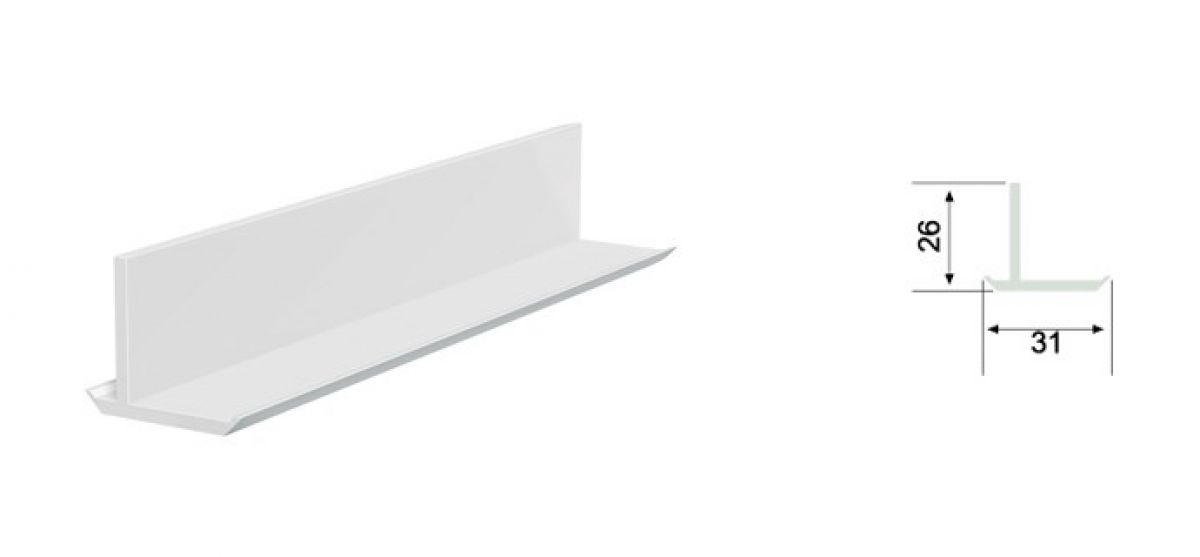

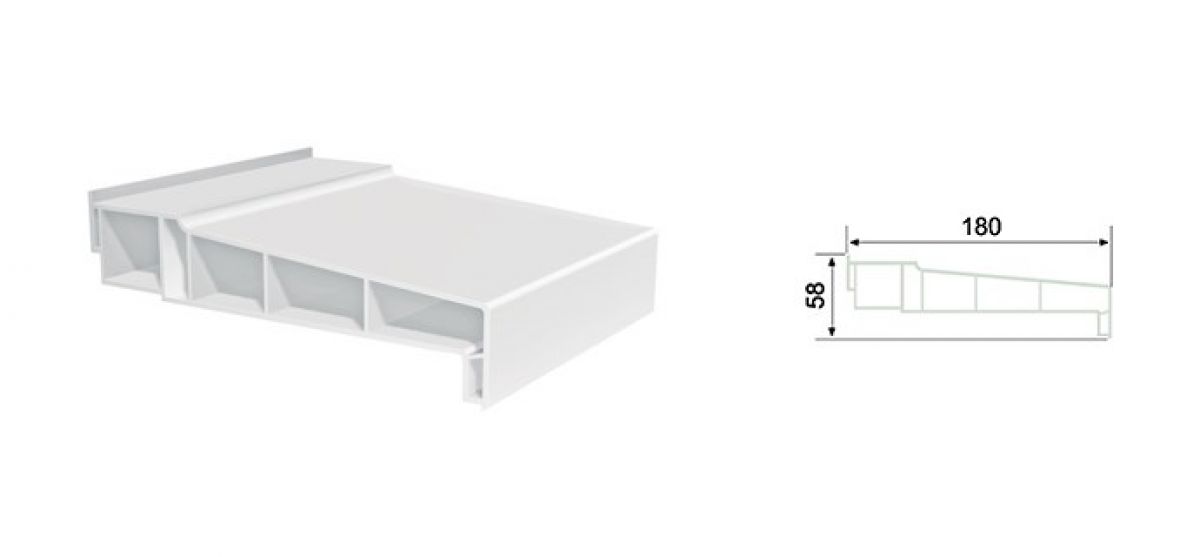

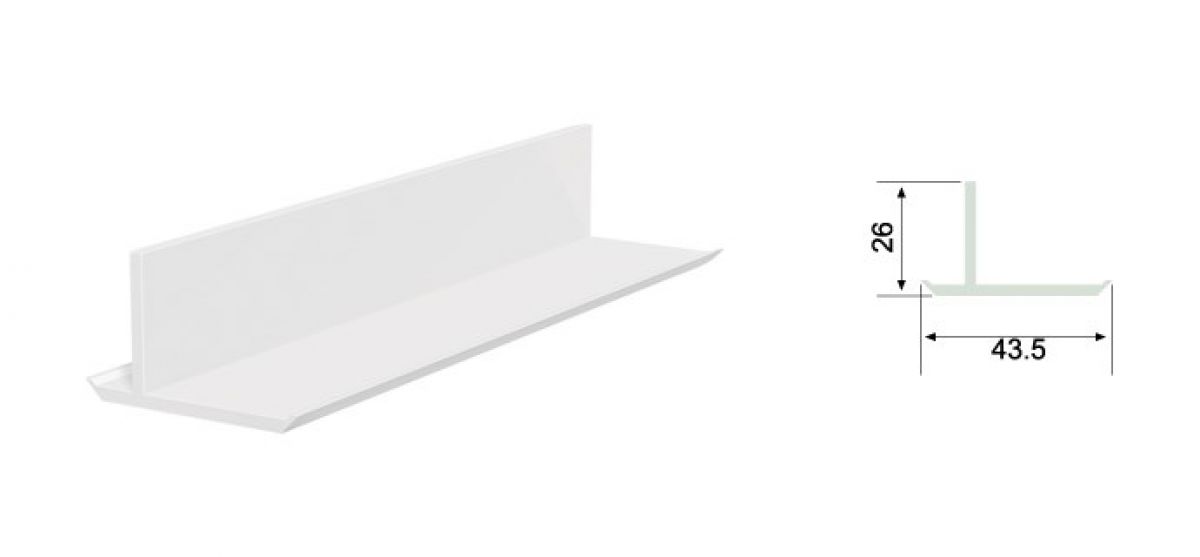

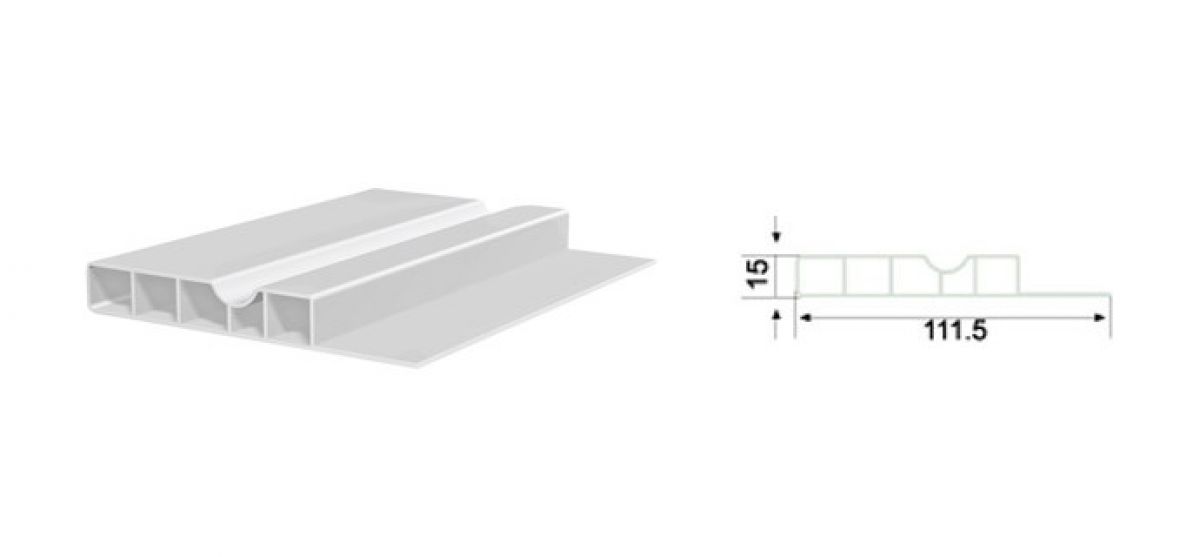

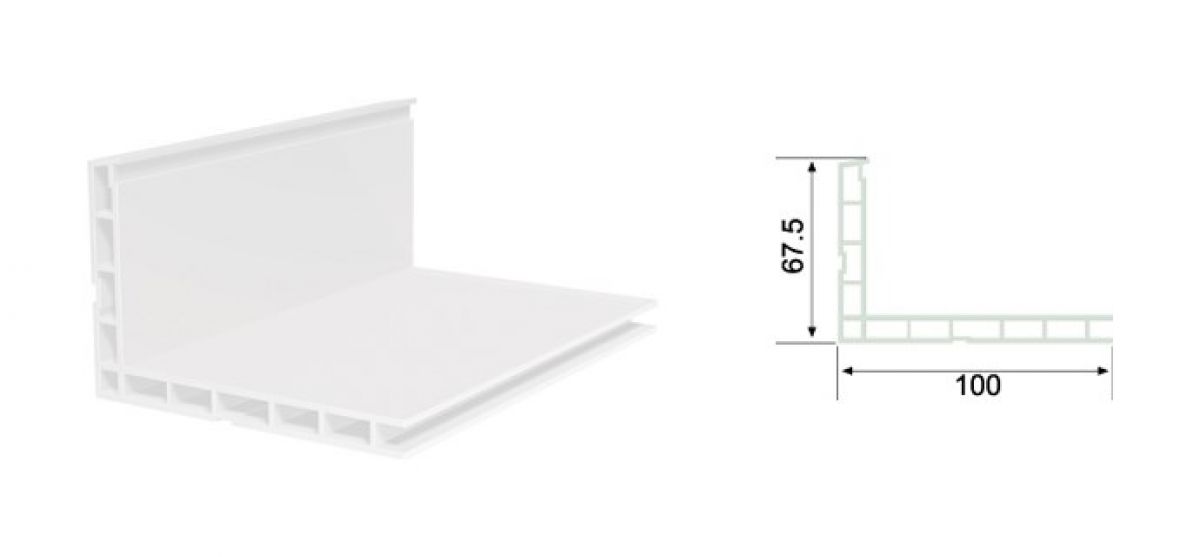

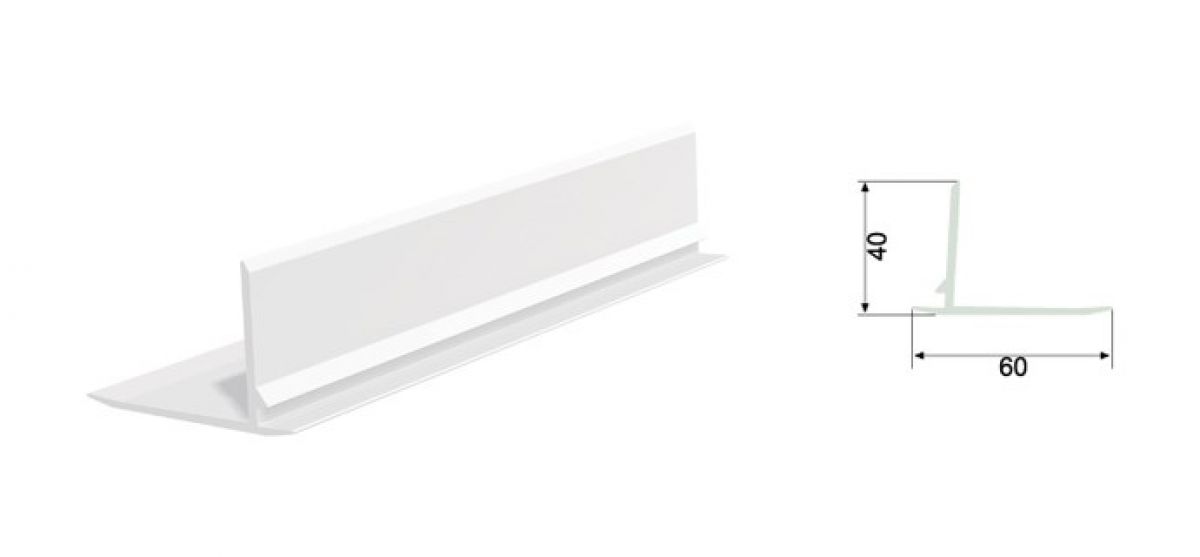

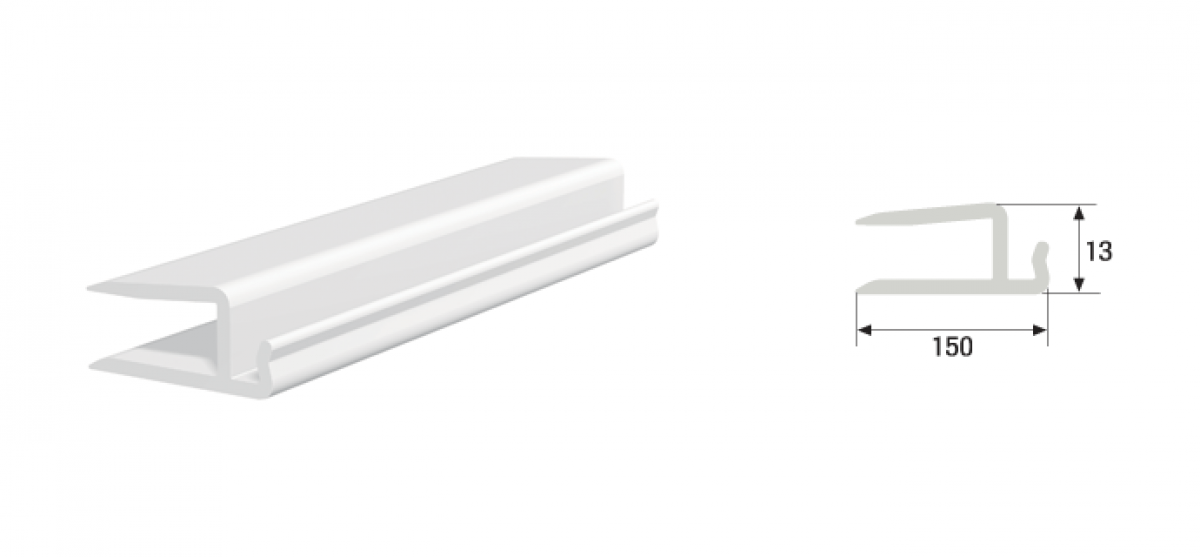

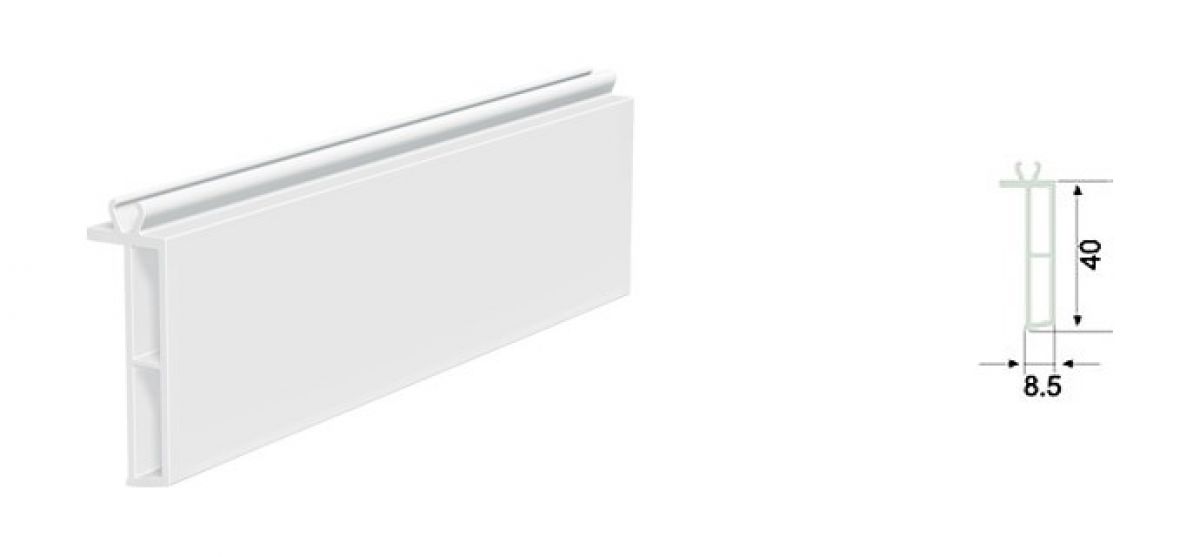

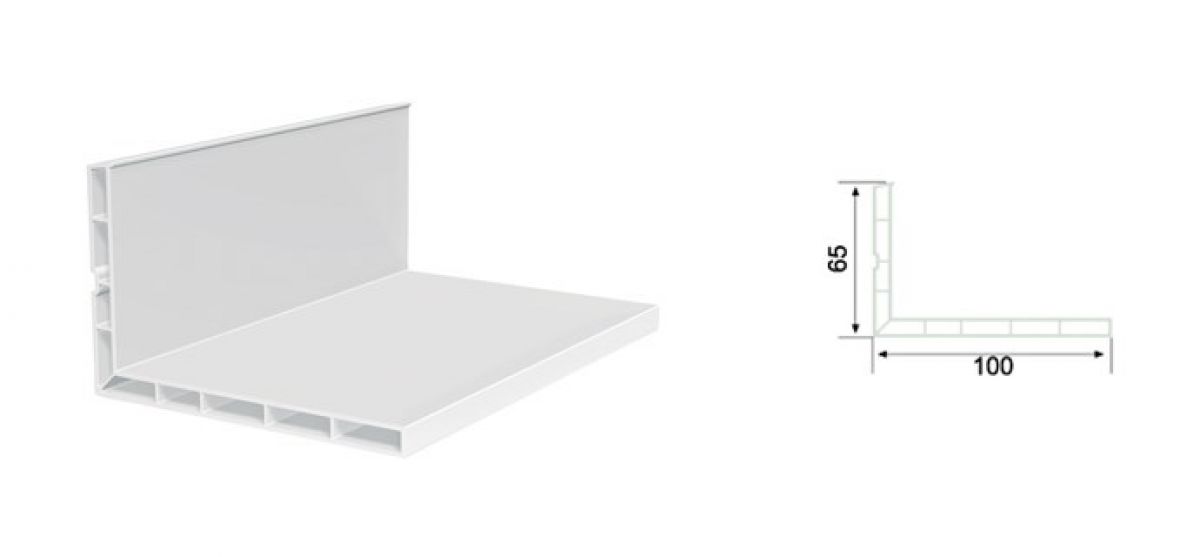

PVC detail profiles used in pvc door and window systems are the pvc profile types used in common in Fıratpen, Winhouse and Gedizpen brands and series which are the pvc window and door systems brands of Fırat.

Detail profiles do not have to be used in pvc door and window systems. Detail pvc plastic profile is preferred by the plastic window practitioner in order to solve possible problems in the application of pvc doors and windows or to meet the demands of the end consumer. It can be used to organize the architectural appearance of the window or to increase its performance, or it can be used to solve an existing application difficulty or problem.

The fact that they do not distinguish between series and brands within Fırat enables them to find more application areas. In addition, since the detail profiles of different manufacturers can differ in size and shape, the product diversity of the sector increases.

Another advantage of detail profiles is that they are not only used in PVC door and window systems. They are used in different sectors such as construction, agriculture sector (greenhouse etc.), pharmaceutical and chemical industry. Detail profiles provide ease of use in different areas due to their corrosion resistance, long life and superior insulation values.

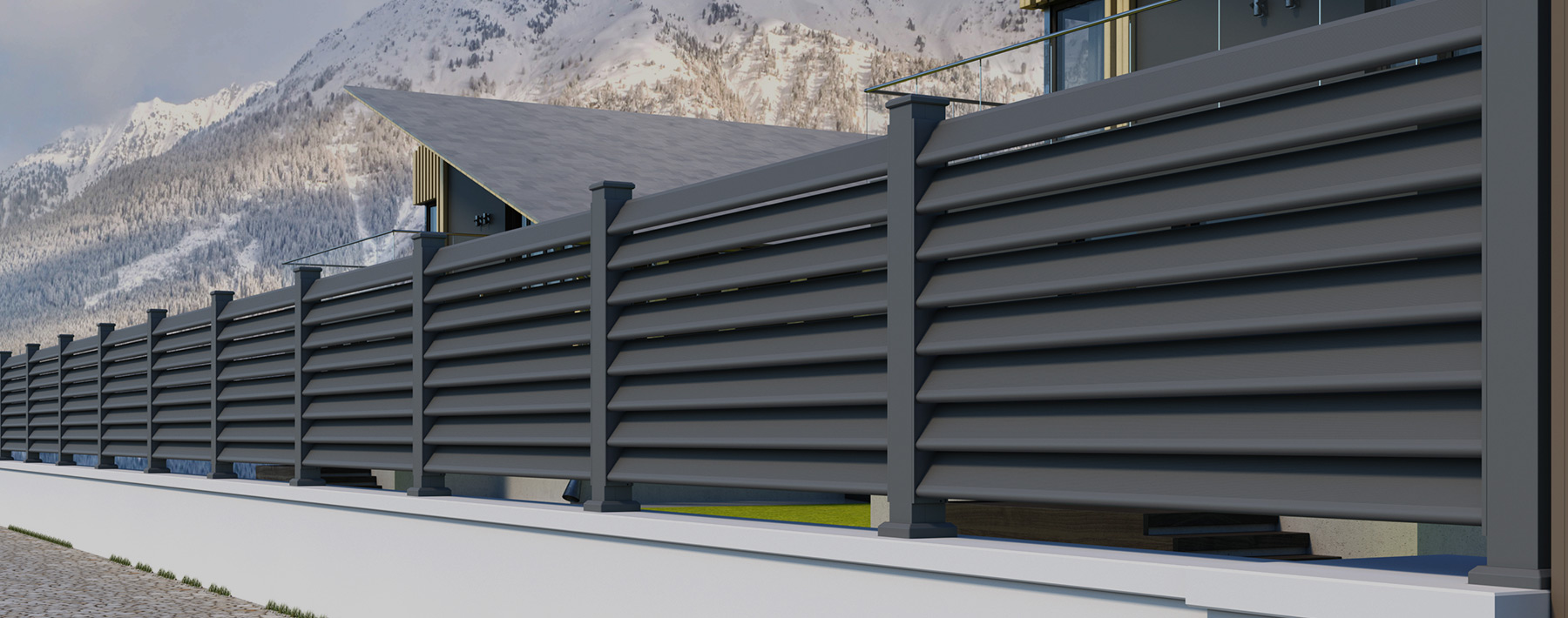

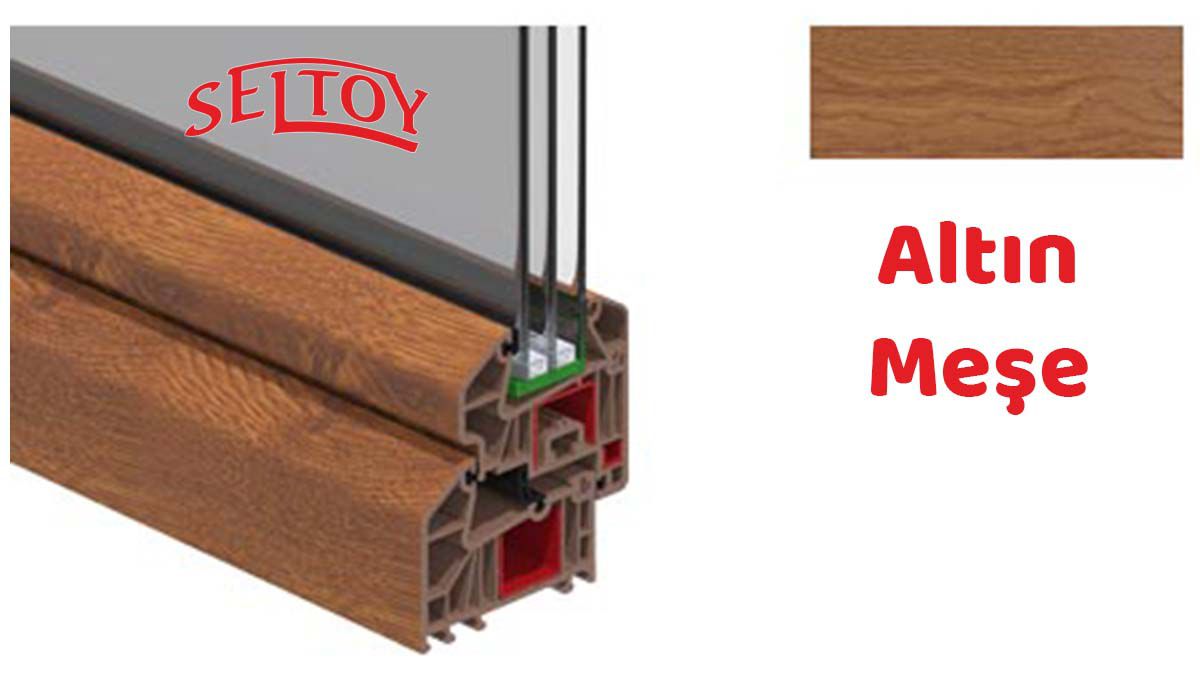

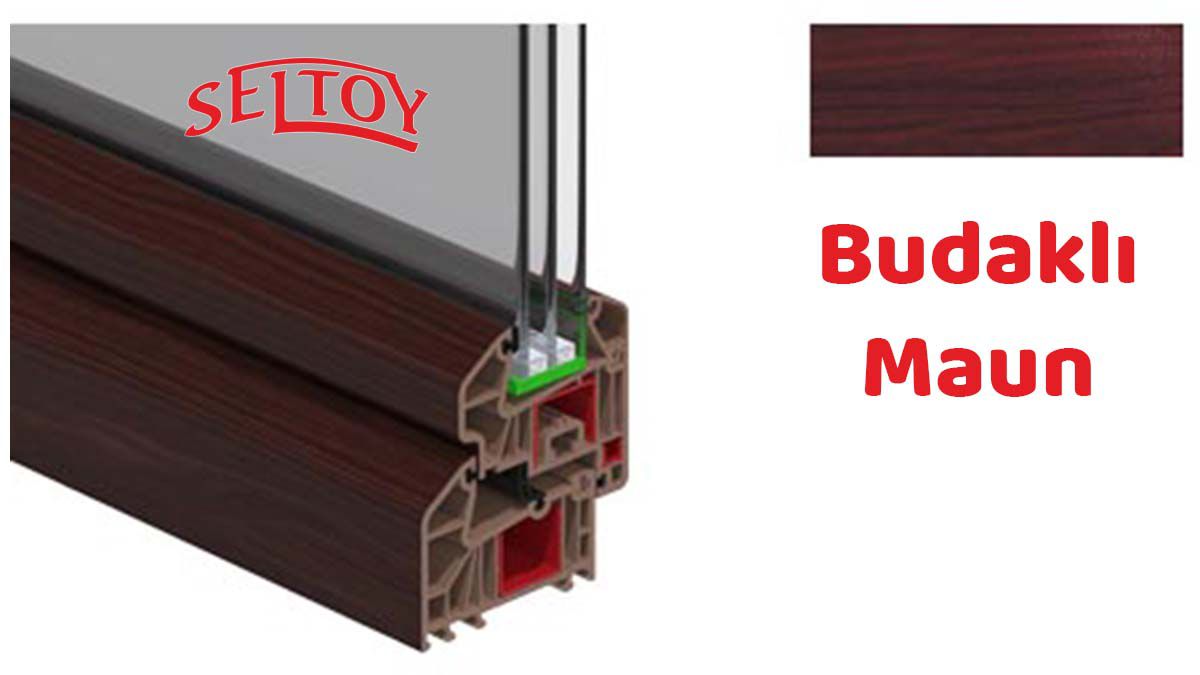

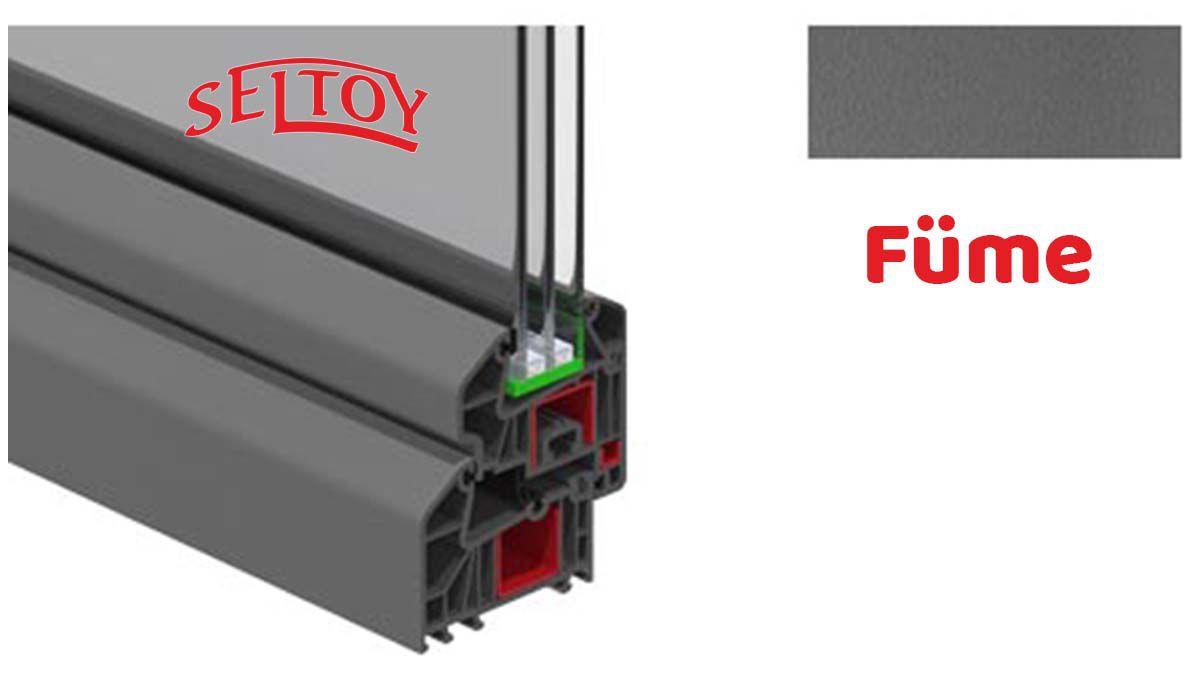

Fıratpen PVC Window and Door Systems with natural wood pattern coated with hot-melt lamination technique in accordance with international standards offer ideal solutions for your unique architectural and special decorative expectations with their rich coating options, aesthetic appearance and functionality.

We have added new colors to our Golden Oak, Gnarled Oak, Gnarled Mahogany, Cedar, Walnut, Gray and Anthracite wood patterned laminated options for your different tastes, projects and decoration alternatives. Your projects and houses are more colorful with our Antique Walnut, Snow White, Anodized Gray, Rustic Oak, Cream, Satin Gray, Midnight Blue, Dark Green, Eagle Black, Chestnut, Silver Gray, Juniper, Smoked, Metallic Gray and Hazelnut colors. You can contact our sales points and us via info@firat.com to meet our 21 different color options in total.

Fıratpen PVC Window and Door Systems with natural wood pattern coated with hot-melt lamination technique in accordance with RAL standards offer ideal solutions for your unique architectural and special decorative expectations with their rich coating options, aesthetic appearance and functionality.

We have added new colors to our Golden Oak, Gnarled Oak, Gnarled Mahogany, Cedar, Walnut, Grey and Anthracite wood patterned laminated options for your different tastes, projects and decoration alternatives. Your projects and homes are more colorful with our Antique Walnut, Snow White, Anodized Grey, Rustic Oak, Cream, Satin Grey, Midnight Blue, Dark Green, Eagle Black, Chestnut, Silver Grey, Juniper, Smoked, Metallic Grey and Hazelnut colors. You can contact our sales points and us to meet our 22 different color options in total.

Window Pattern Options Available in Our Stocks

When choosing between pvc door and window systems, it is necessary to consider 9 different factors that make up the systems.

All these factors affect the quality of pvc window systems more or less, but directly.

1. PVC Profile:

The first and most important condition for obtaining quality pvc joinery is to use quality pvc profiles. A pvc profile that fulfills the requirements of the standards, does not cause problems technically and during application, provides the required insulation values, and has effective and widely used quality certificates should be used. A pvc profile that meets these criteria is a prerequisite for a pvc joinery that meets the standards.

2. Support Sheet:

The biggest contribution of the support sheet to the pvc window is to form the skeleton and increase the strength. In addition, it has benefits such as preventing the structure from changing shape in the face of thermal changes, providing assembly strength and ease of connection, etc. The support sheet should be used in accordance with the shape of the PVC profile and it should not be neglected to apply a single piece of support sheet to each meter of each main profile possible in PVC joinery. Today, no other product has yet been developed that can replace metal support sheets one-to-one.

3. Gasket:

The most effective insulation material in PVC door and window systems is the gasket. Today, EPDM rubber and TPE plastic based seals are used.

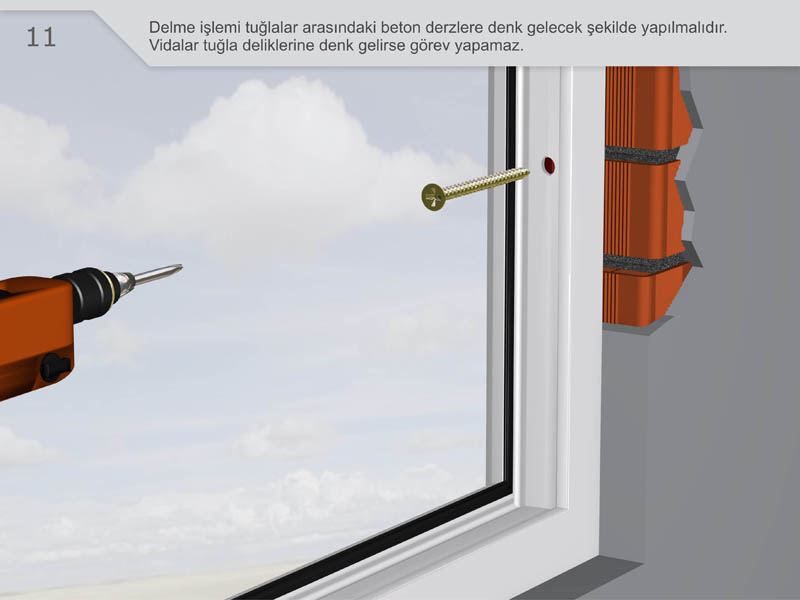

4. Connection Elements:

Fasteners in PVC door and window systems gain importance according to the geometric shapes of doors and windows and their location. In the fastener group consisting of screws and connection wedges, metal (zamak) materials with high abrasion resistance and coating that are not affected by climatic conditions and corrosive factors should be used.

5. Accessories:

They are the mechanisms that form the moving parts in PVC door and window systems and enable the movement to occur. Systems with quality certificates, high corrosion resistance and ease of use should be selected. Measurement criteria must be strictly followed.

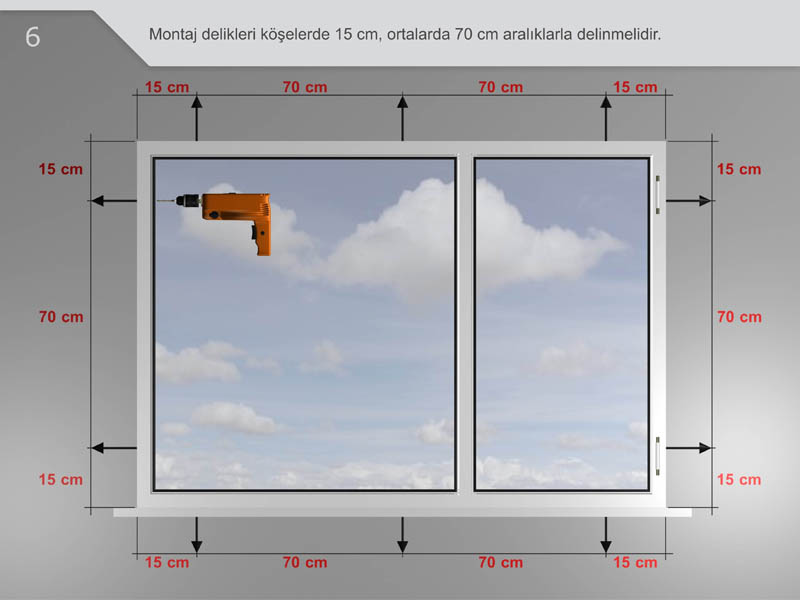

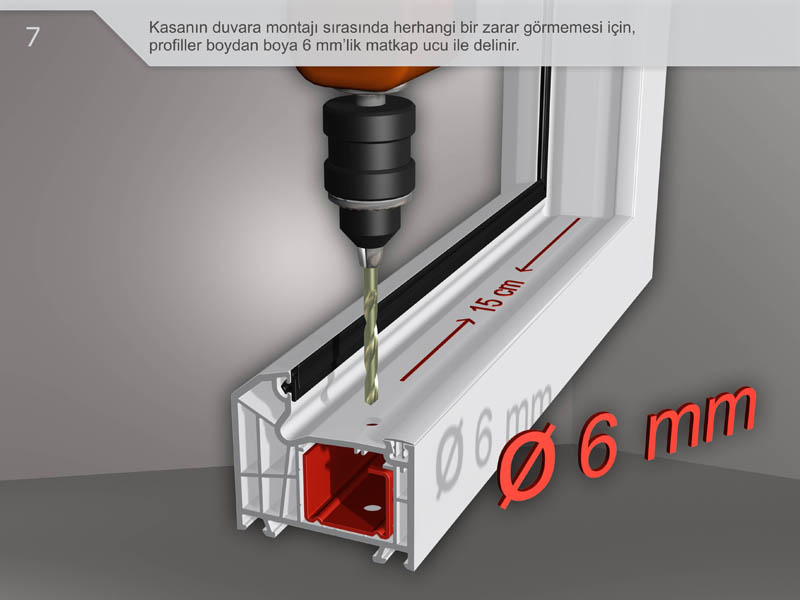

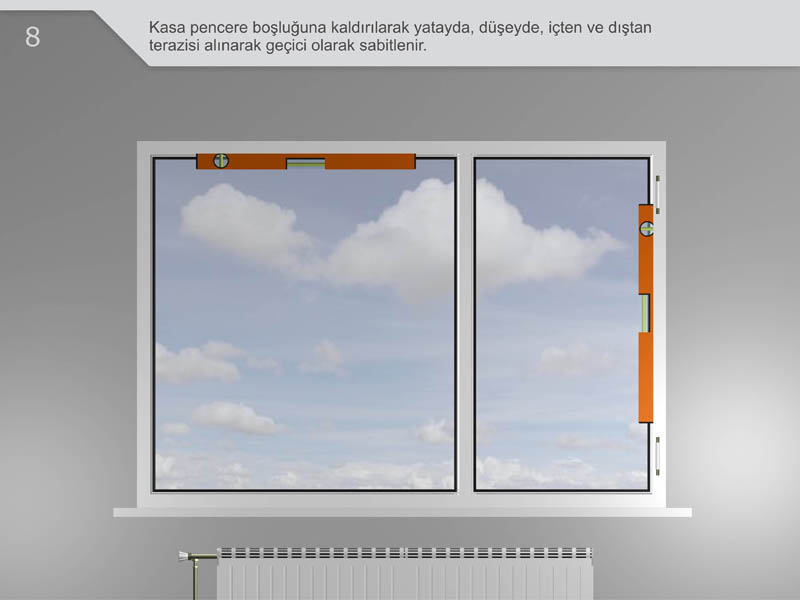

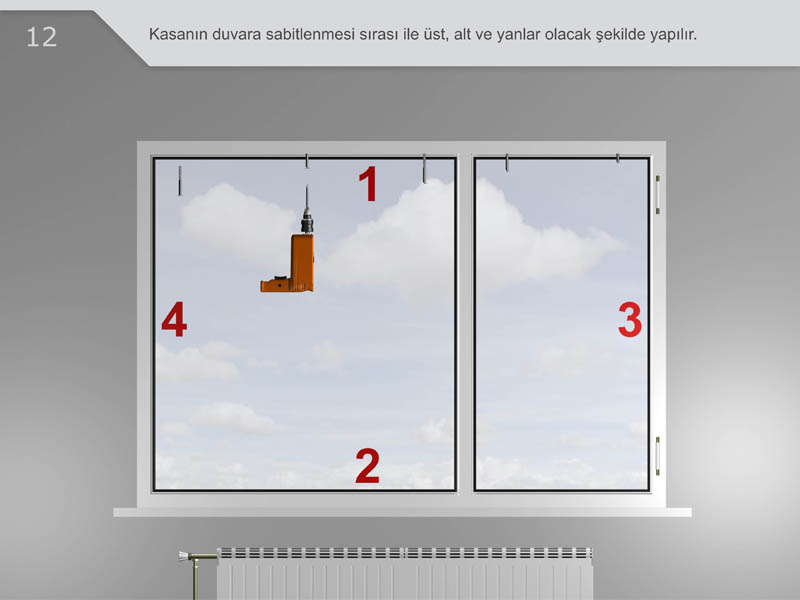

6. Assembly Materials.

These are the materials that ensure that the pvc joinery is mounted on the wall in a healthy way and fulfills its function. Materials that are long-lasting and will not cause strength weakness over time should be selected.

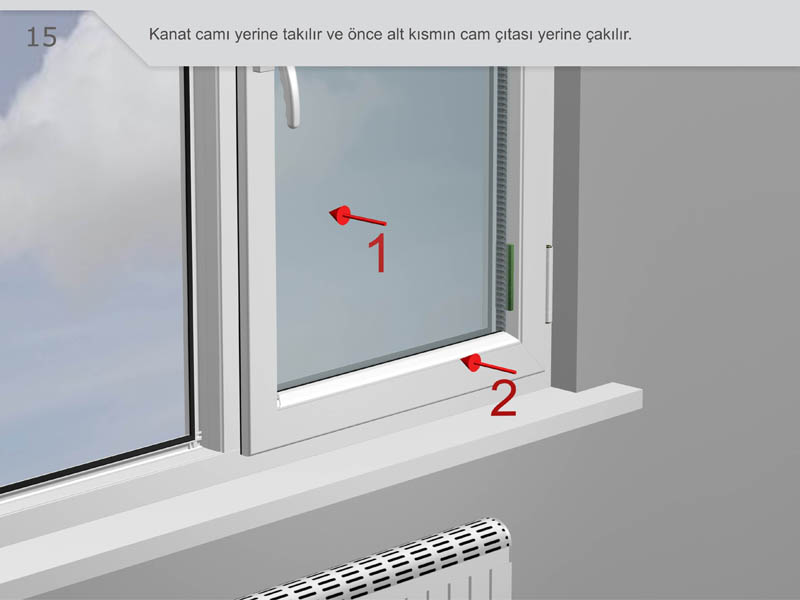

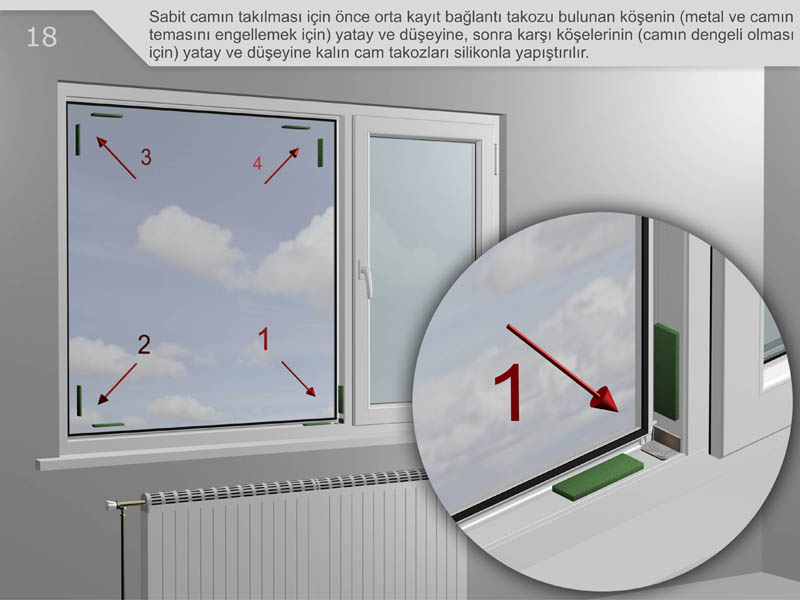

7. Glass:

They constitute the largest part in terms of area in PVC door and window systems. It is the most effective element for heat and sound insulation. Glasses that do not disrupt the architectural structure, do not overload the system, help the movement to be completed in a healthy way and have quality certificates should be used. Especially in double glazing systems, the preference for “insulating glass synergy” and “insulating glass comfort” has increased as they provide heat and sound insulation.

8. Extras:

Extras are all other requests of the end consumer that add to PVC door and window systems, visual improvement and performance enhancement. It can be defined as moldings, paneling, carpentry, marble and special opening systems.

9. Labor:

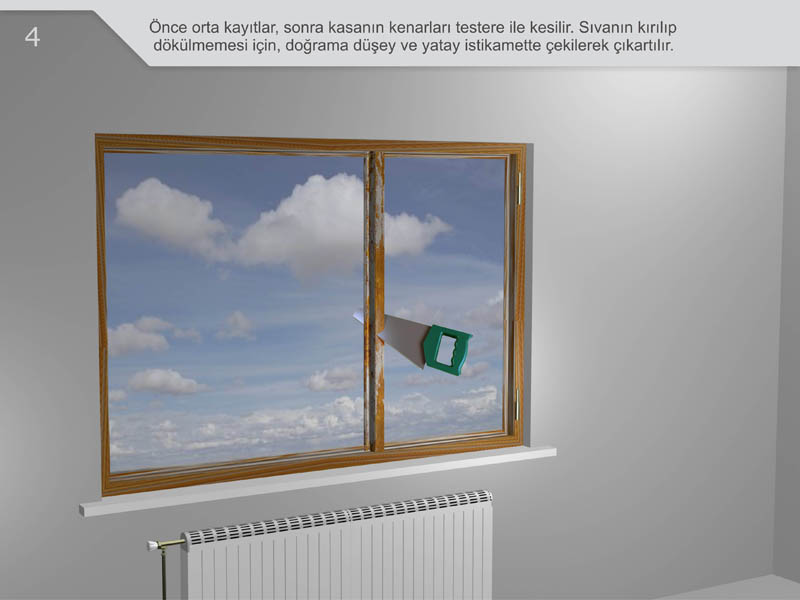

One of the biggest factors affecting the quality of pvc window systems is workmanship and assembly. It is possible to make a very bad pvc joinery – plastic window from a first class pvc profile, as well as a good pvc joinery from a bad pvc profile.