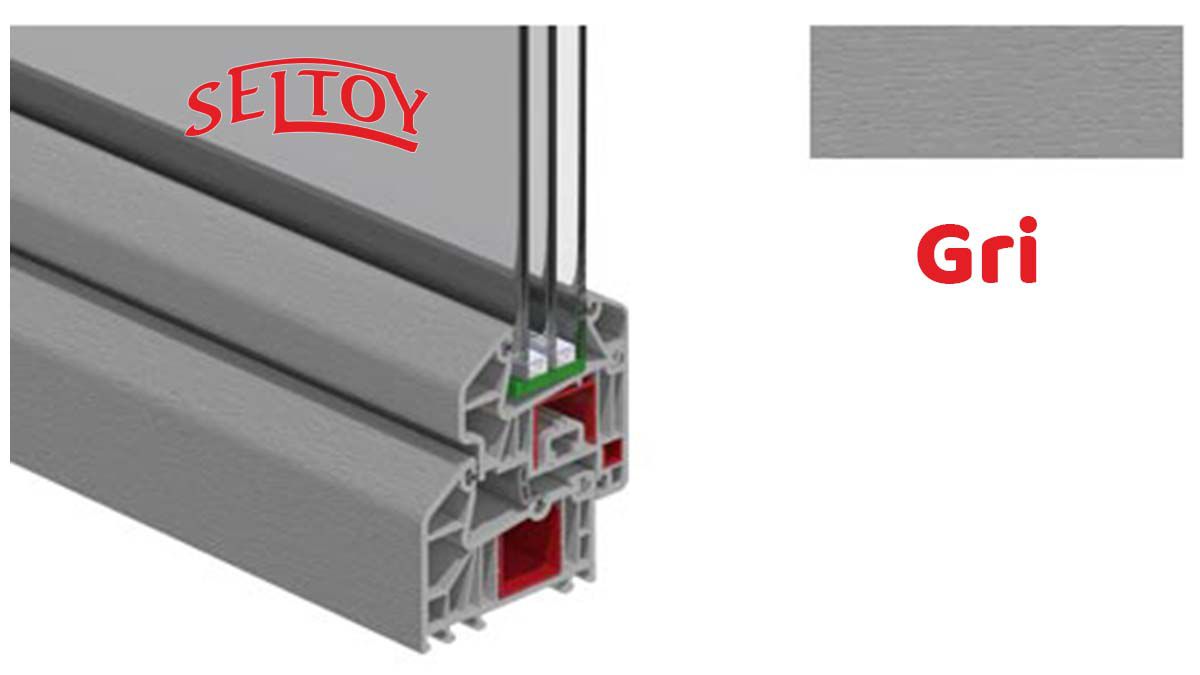

Sliding PVC Window Series

HIGH INSULATION PERIOD IN SLIDING SYSTEMS

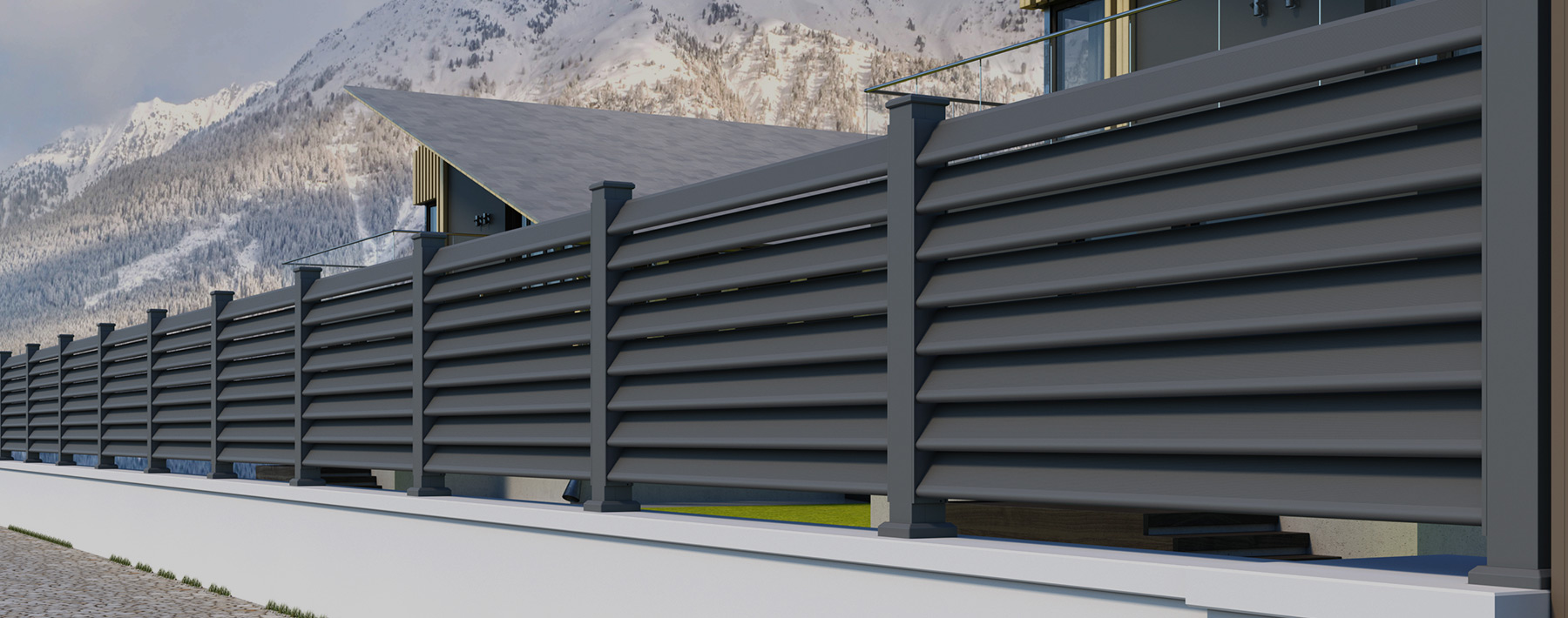

Developed with Fırat technology for limited and narrow areas where normal door and window openings are not possible, Fıratpen Sliding Window provides ideal solutions in many areas with its superior heat and sound insulation values, aesthetic and decorative appearance, practical use and functional solutions for wide openings.

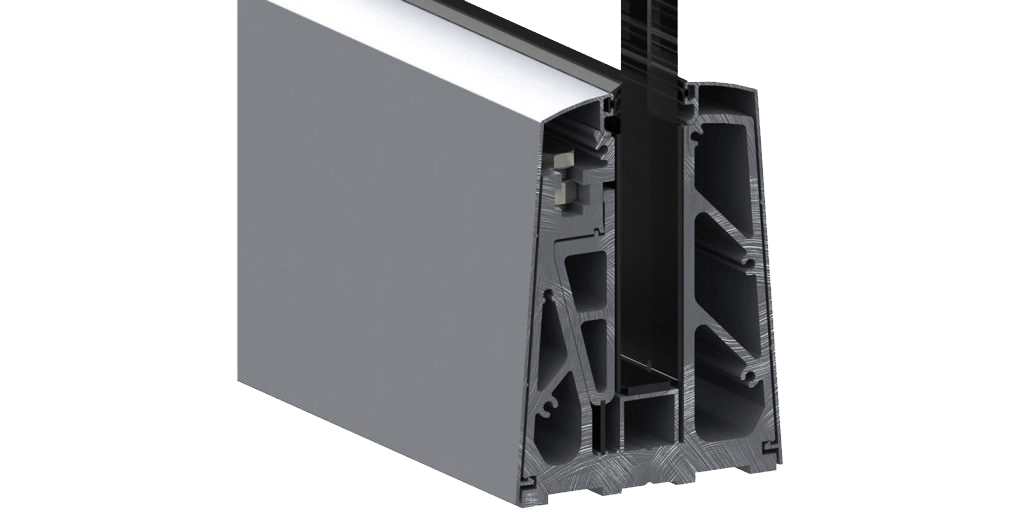

EPDB Gaskets

top level insulation

EXPERIENCE, TECHNOLOGY AND DESIGN UNITED IN zenia slide

Today, saving and efficient use of energy is as important as energy resources. In building complexes, 82% of energy is used for heating. This rate corresponds to 26% of the total energy used in our country. Of the heat loss in buildings, 40% comes from walls facing outwards, 30% from windows, 17% from exterior doors or balcony doors facing outwards, 7% from the roof and 6% from under slabs. This situation highlights housing as one of the most important areas to save money and PVC window systems as insulation systems. The fact that energy is the most limited and expensive resource brings "energy conservation", in other words insulation, to the forefront in window systems.

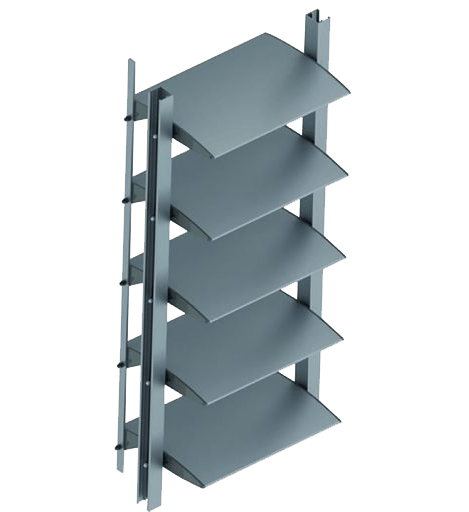

Zenia Slide Fully Insulated Sliding

System

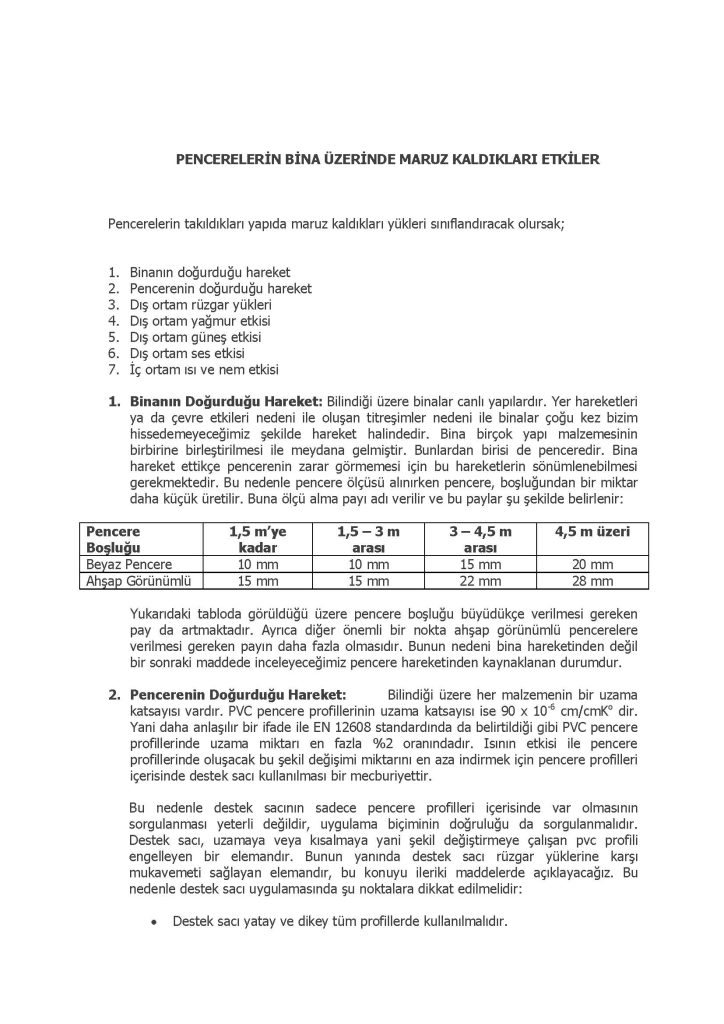

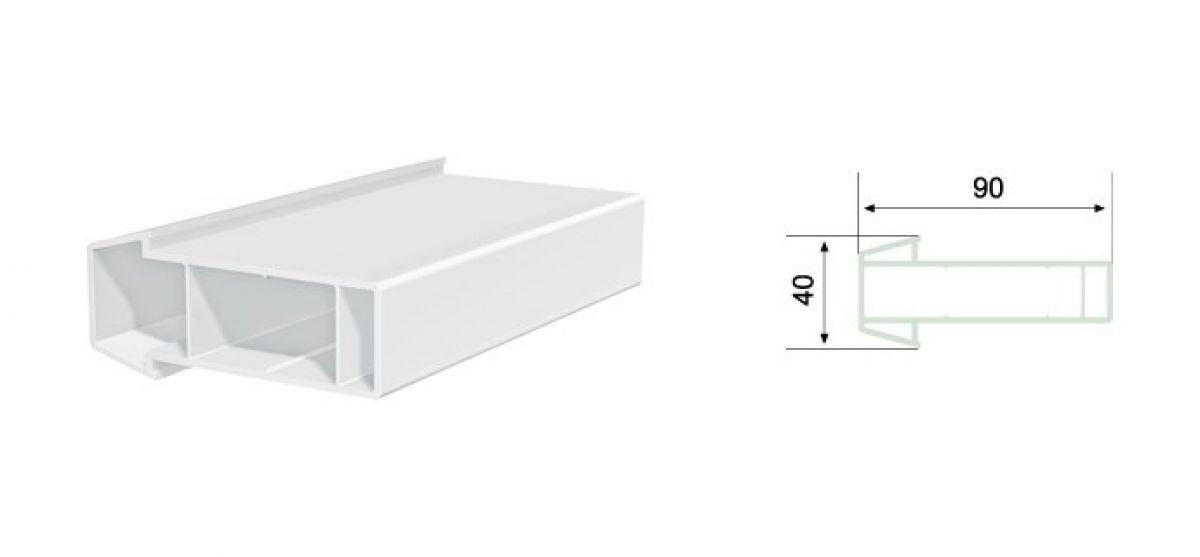

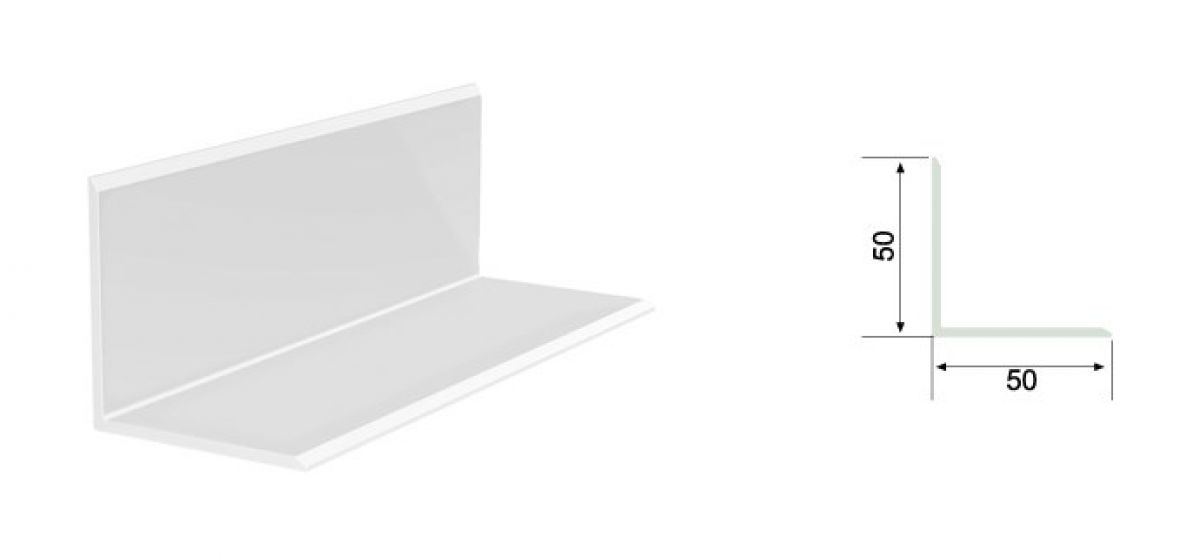

- The system has a frame width of 125 mm and a sash width of 50 mm.

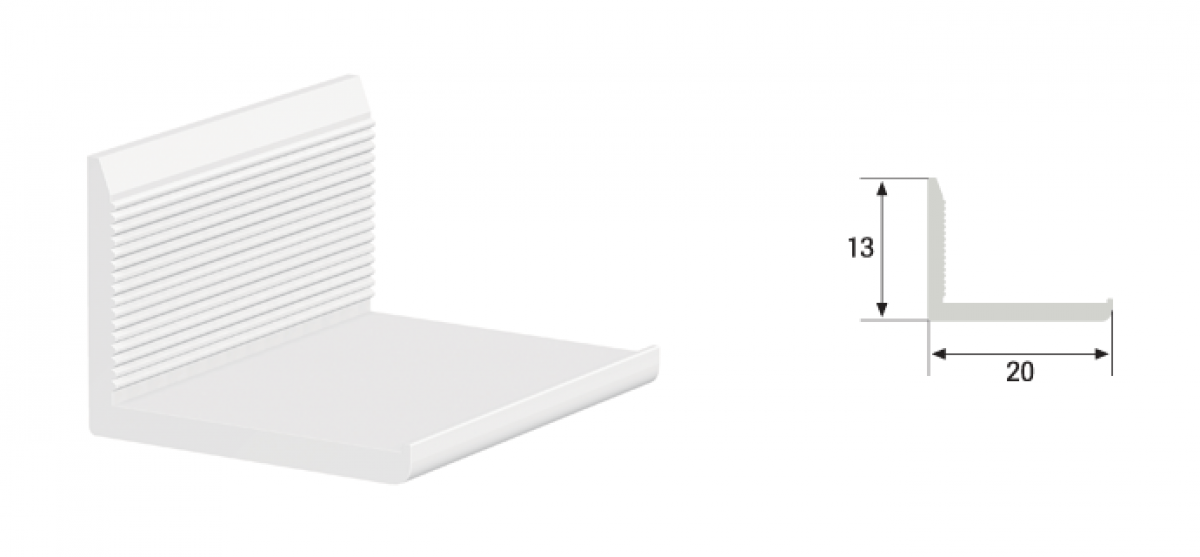

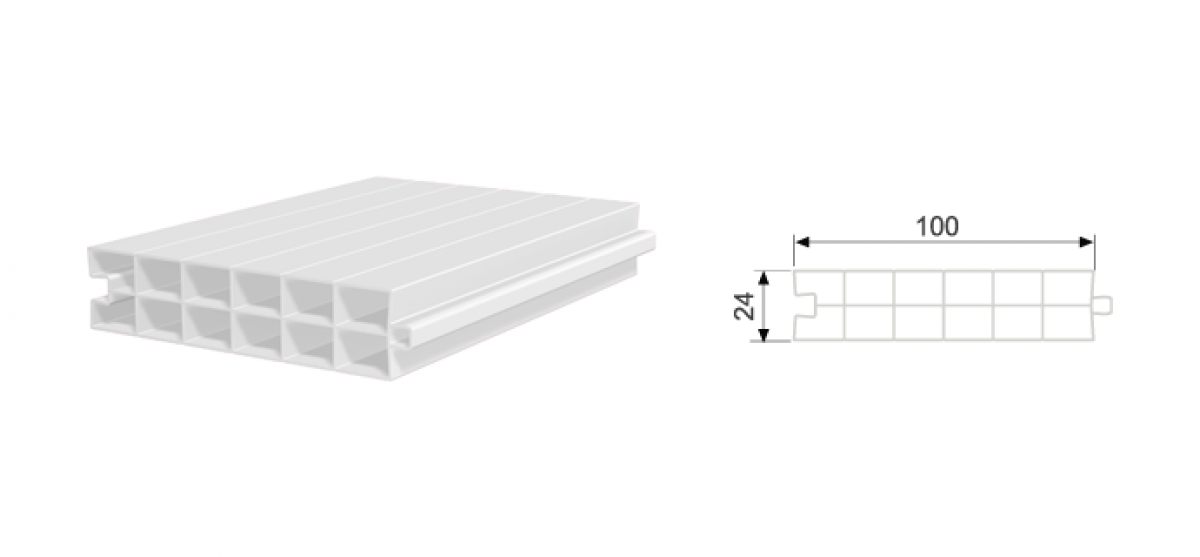

- Two different lath types, 20 and 24 mm, can be used.

- When the window is closed, all joints are sealed with EPDM seals.

- Two different aluminum rail profiles have been developed for doors and windows to ease the passage through door thresholds.

- While the joining of the frame and sash profiles of the system is provided entirely by the "welding method"; the system is designed in such a way that it can be produced in the fastest way with the minimum profile.

- Since each sash has a carrying capacity of 200 kg, it is possible to apply from small windows to large openings.

- Wing joints are the biggest weakness of sliding systems. Thanks to the special interlock profile used at the sash joints, insulation is provided with two EPDM gaskets and hair seals.

- Thanks to the special locking system of the Interlock profiles, the possibility of the wings separating from each other due to the wind effect is completely eliminated.

- Another weakness of the sliding and parallel sliding systems, the gap at the junction of the two wings on the upper horizontal is eliminated with a specially designed insulation profile and wedge.

- The integrity of the system is not compromised thanks to the special profile designed to make the gap between the frame and the sash on the upper horizontal aesthetically appropriate and to close this gap.

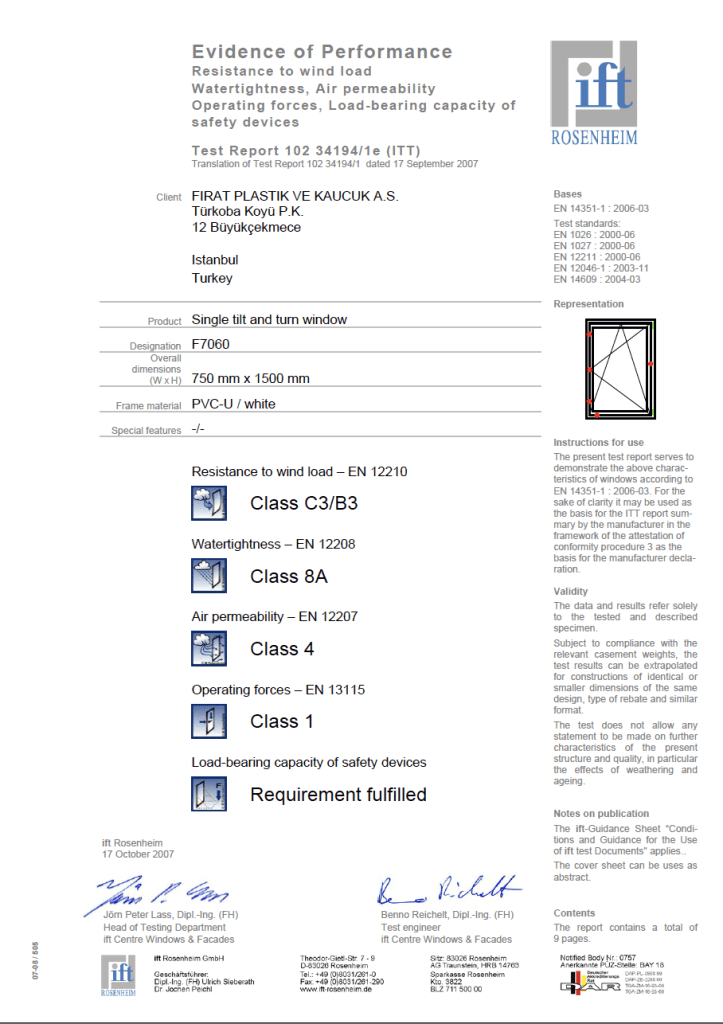

Wind Load Resistance

- Thanks to its locking system and interlock structure, the "Insulated Sliding System" has high wind load resistance and can provide the same performance values as highly insulated window systems in air tightness.

- While developing the "Insulated Sliding System", the maximum wind load values that the buildings can be exposed to were taken into consideration, and the structure of the support sheets and their positions in the profile were designed in such a way as to obtain maximum efficiency.

Thermal Insulation

- The "Insulated Sliding System" is able to meet all the requirements in terms of heat conduction coefficient values thanks to the number of chambers, chamber widths, profile heights and EPDM gasket system created by considering the profile width.

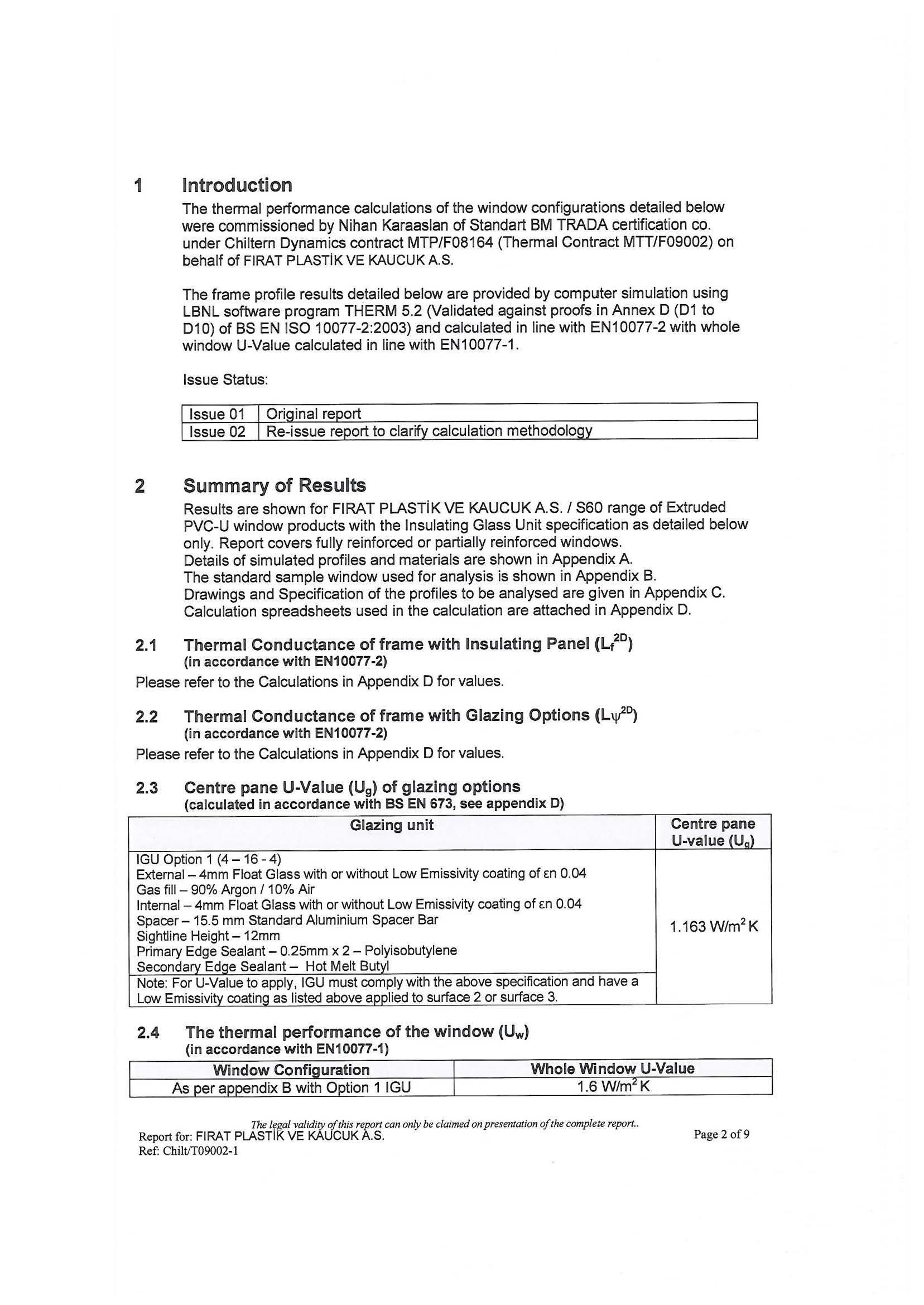

- In accordance with TS EN ISO 10077-2 standard, with a window system measuring 1.23 m x 1.43 m, Ug : 1.1 W/m2K, Uw : 1,6 W/m2K and Uf : 1,7 W/m2K values were achieved.

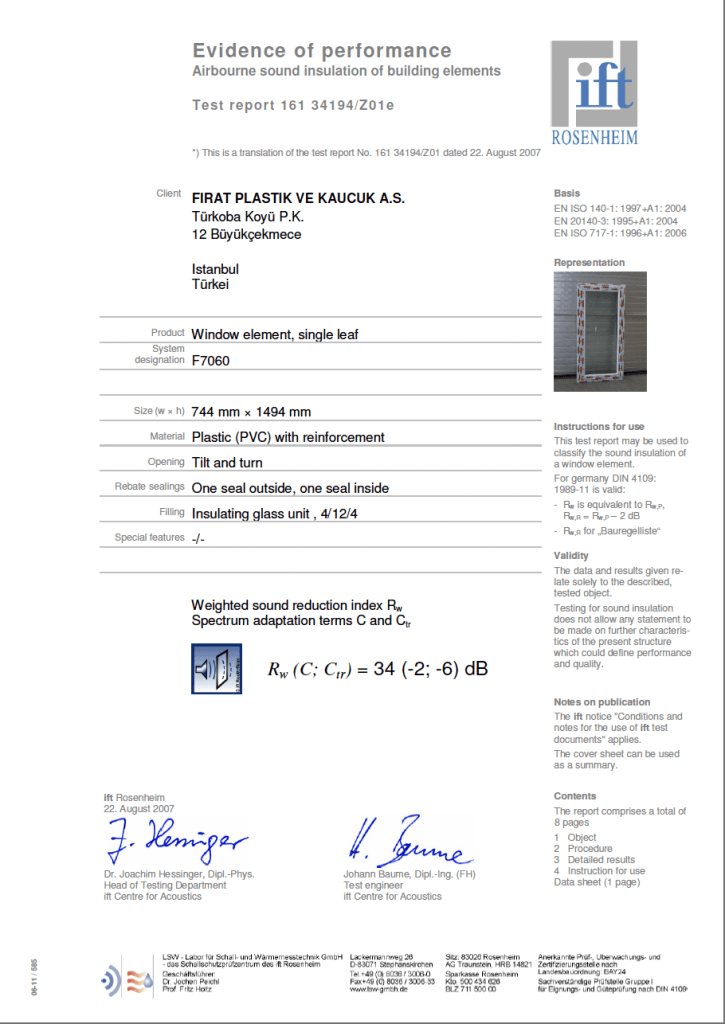

Sound Insulation

- Sound insulation up to 40 dB can be achieved with the "Insulated Sliding System". Thus, it is possible to create a sound environment at a quality living level even in the noisiest environments.

- With the sound isolation created by the acoustic glasses that can be used with the system, the sound noise of the outside world is isolated from the indoor environment in the most effective way.

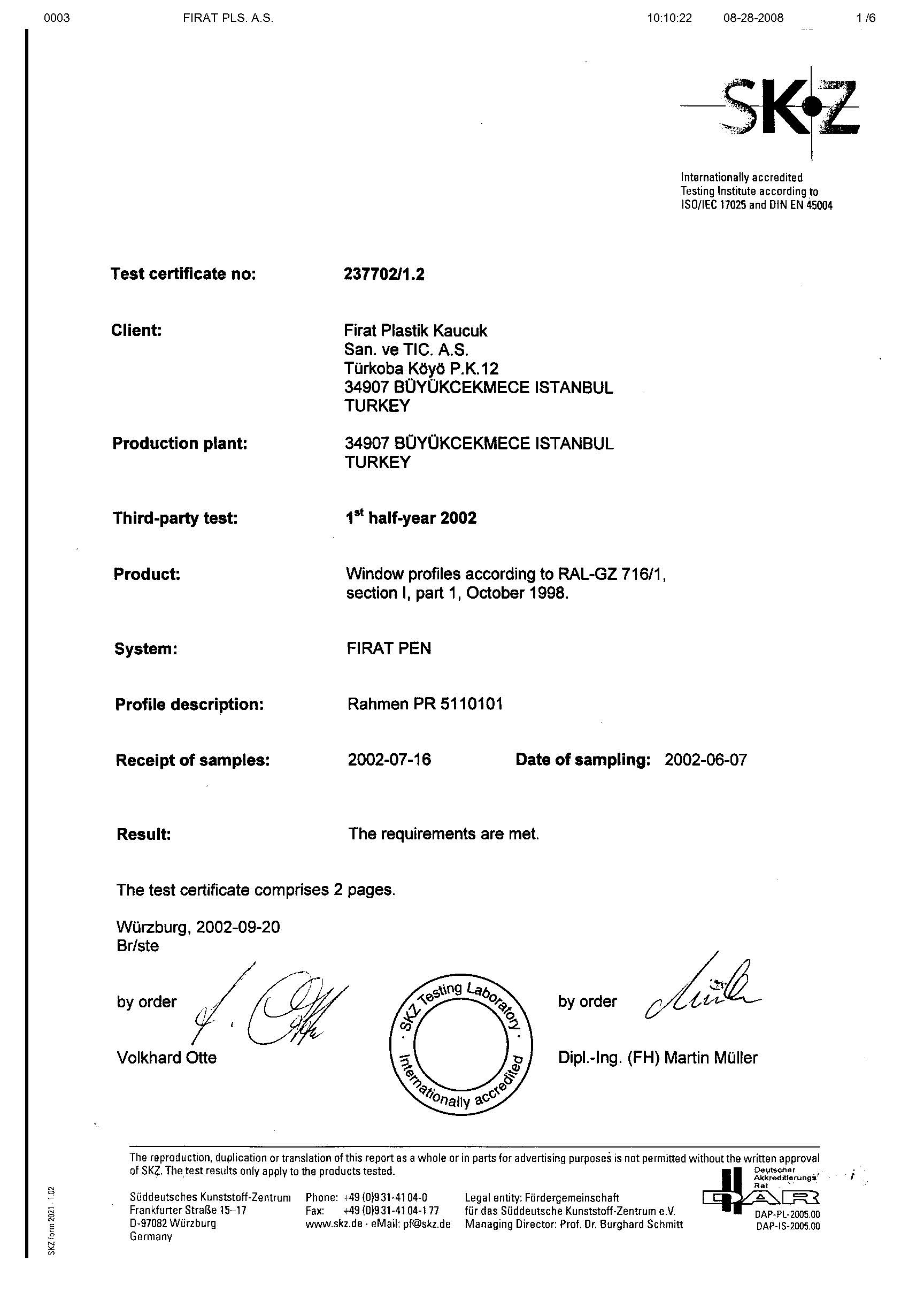

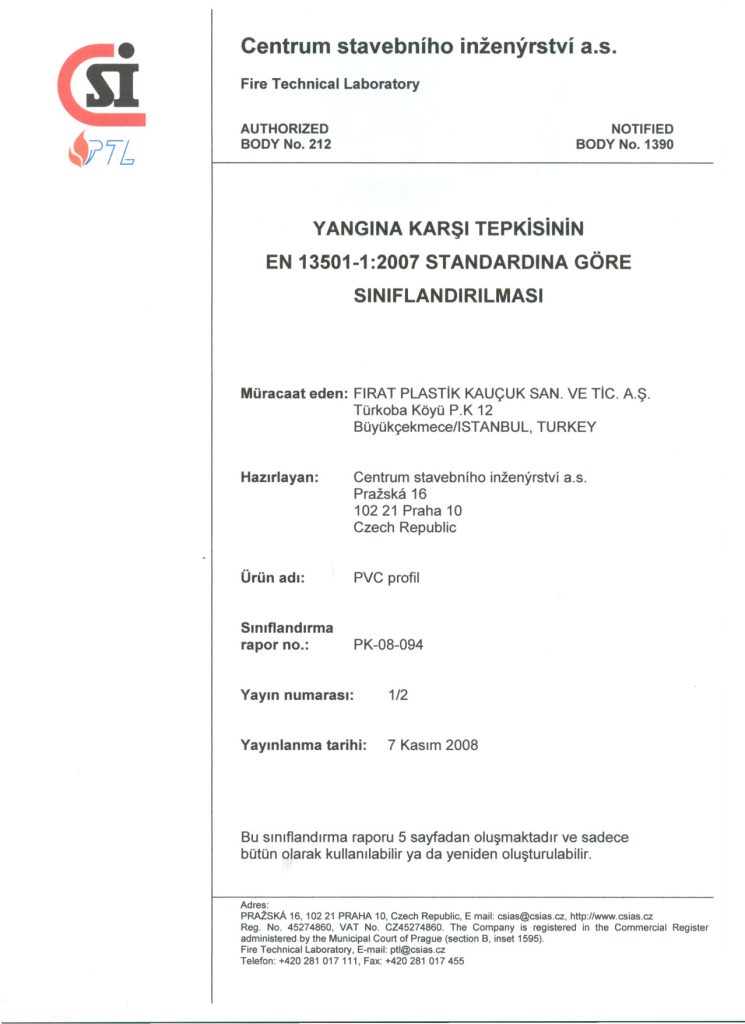

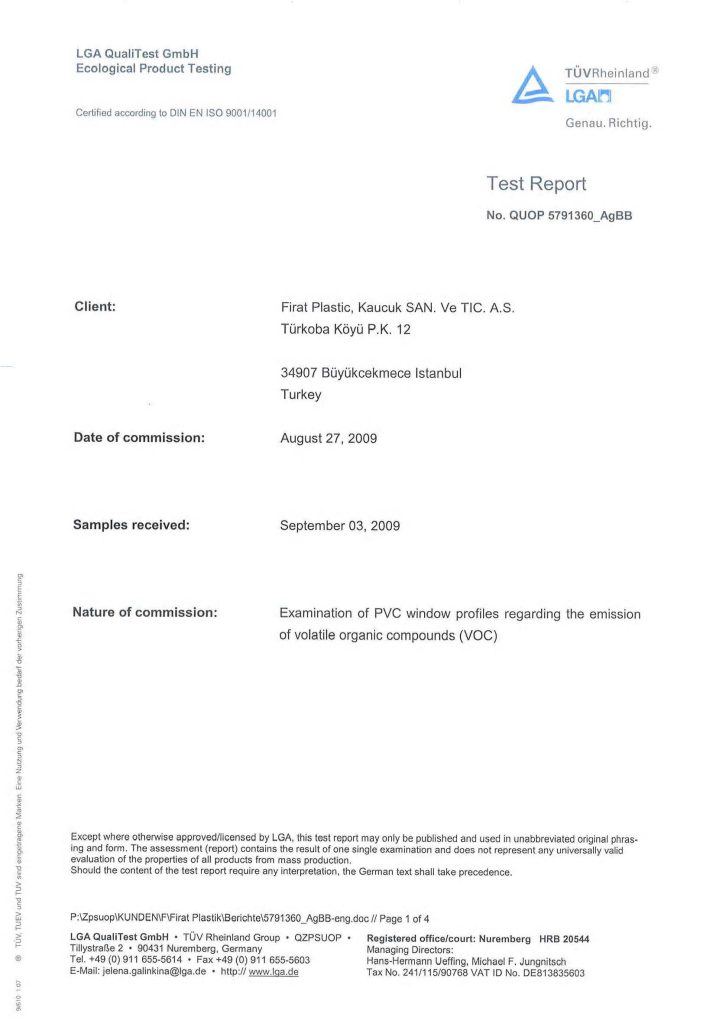

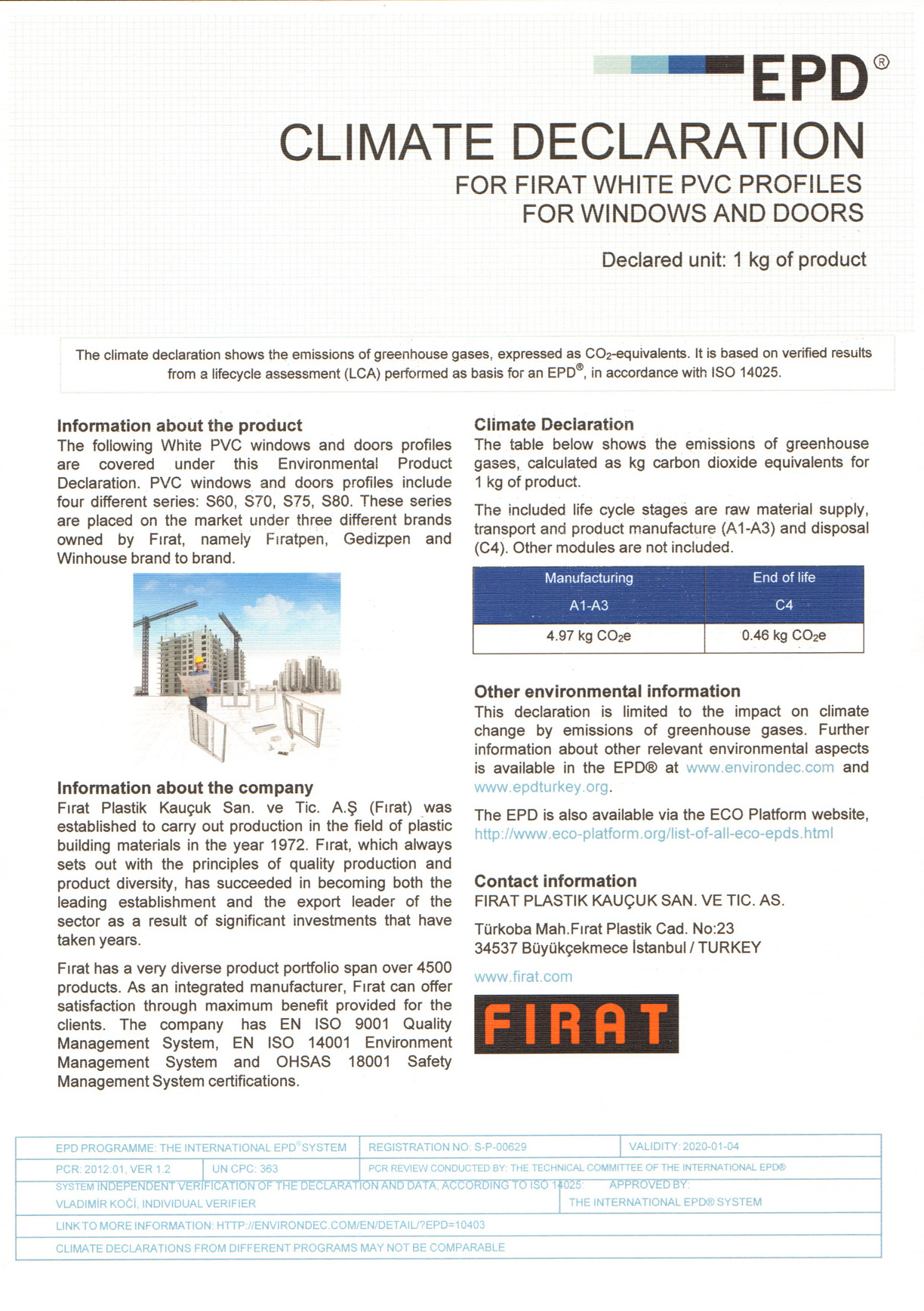

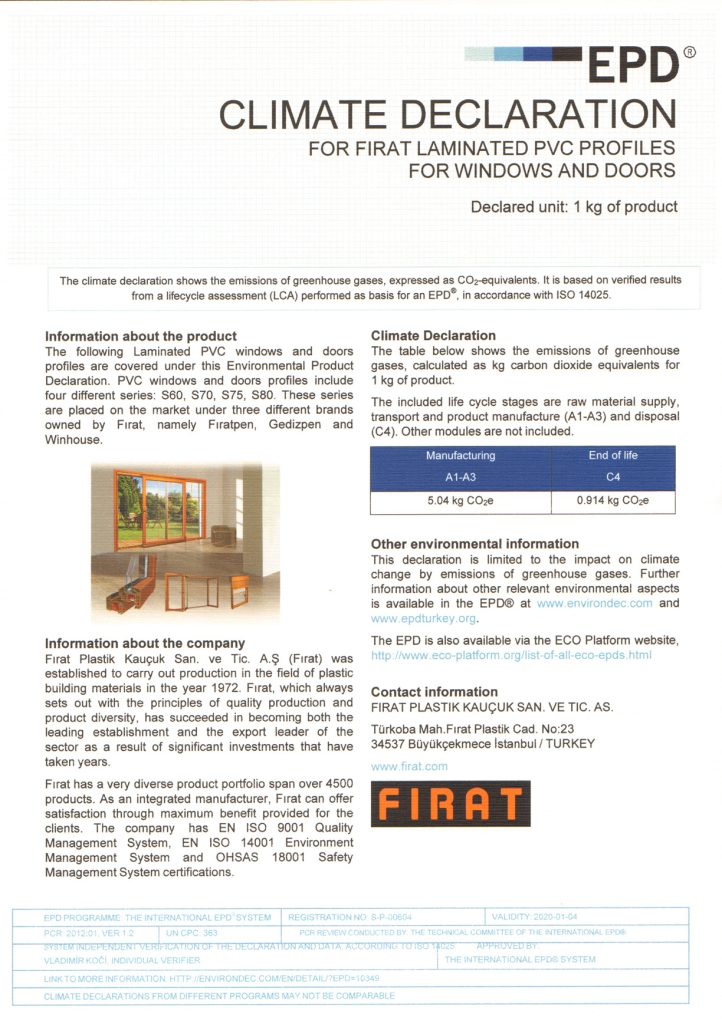

Quality Certificates & Technical Documents

- Quality Certificates

- Technical Brochures

- Test Reports

- System Documentation

- Environmental Product Certificates

Window and Door Details

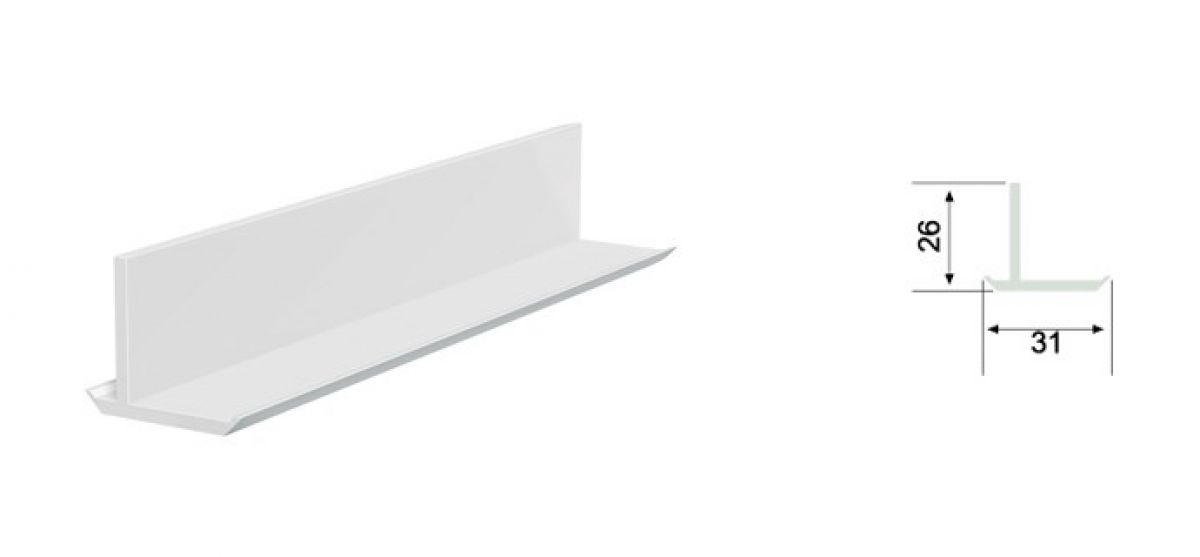

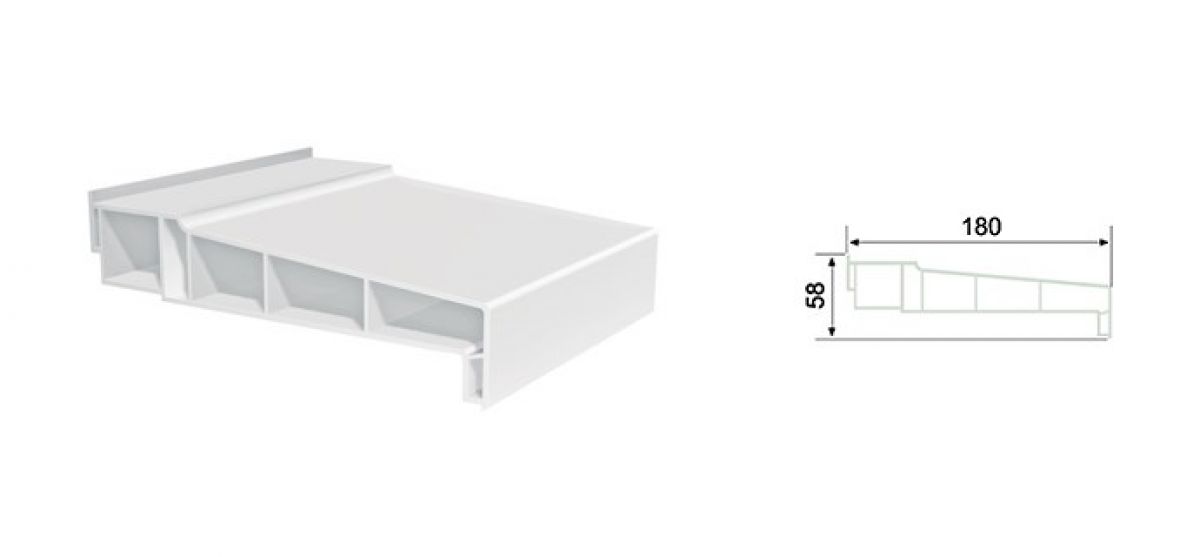

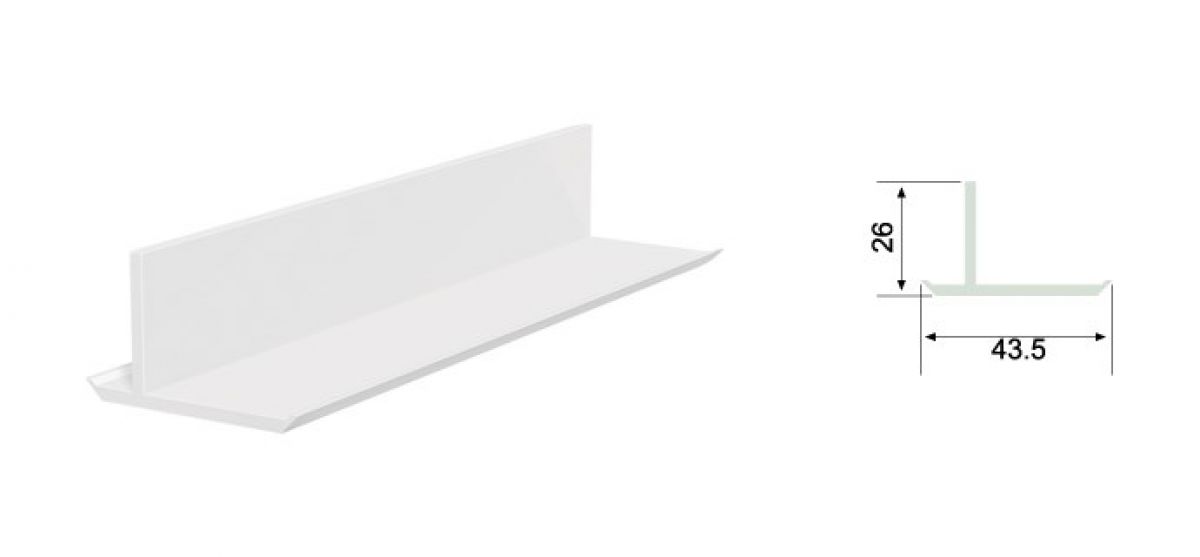

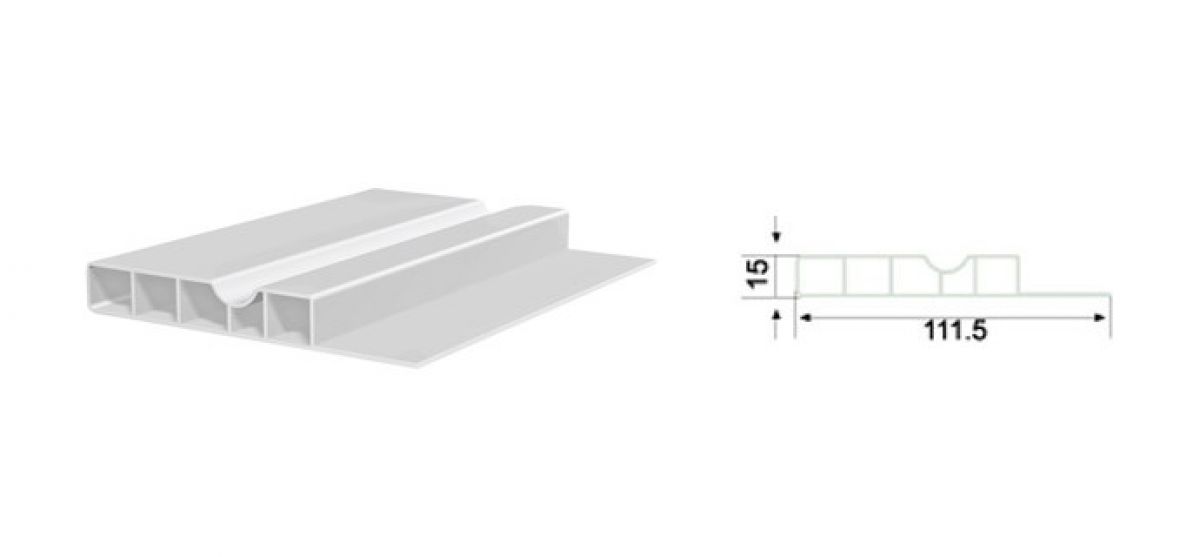

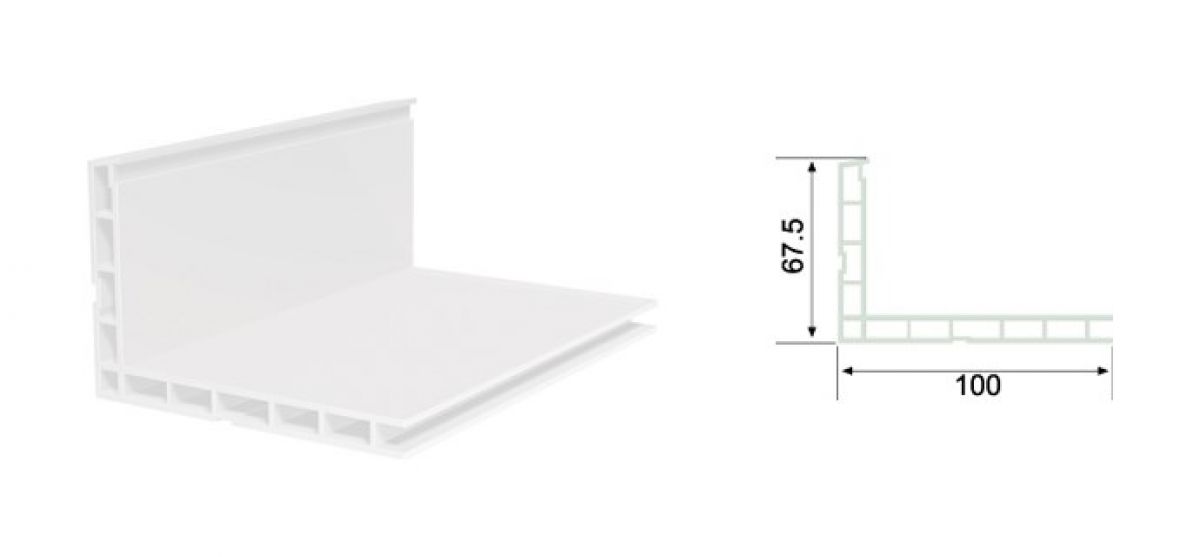

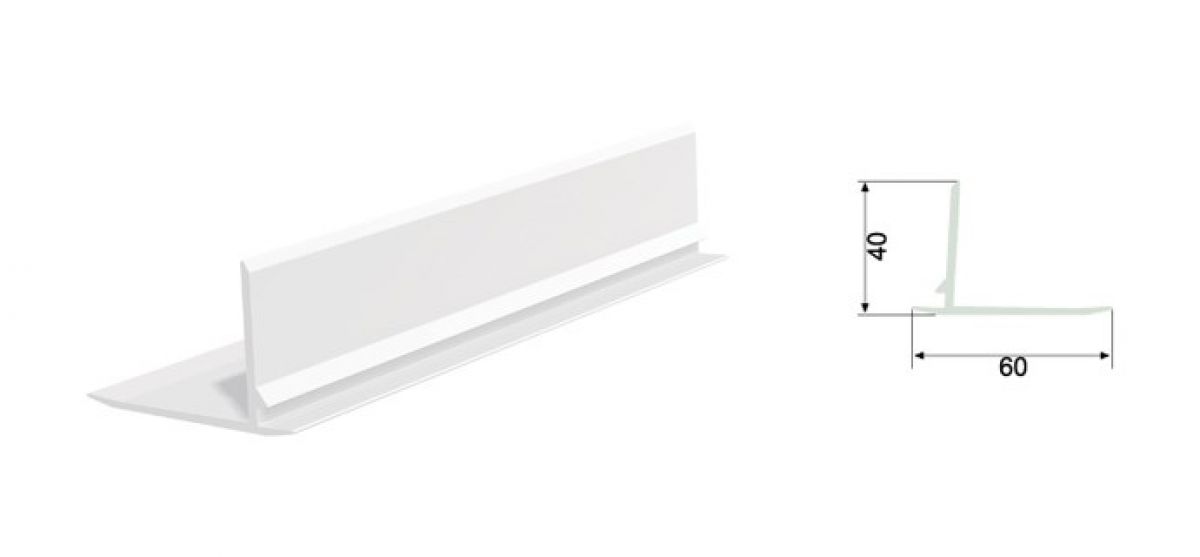

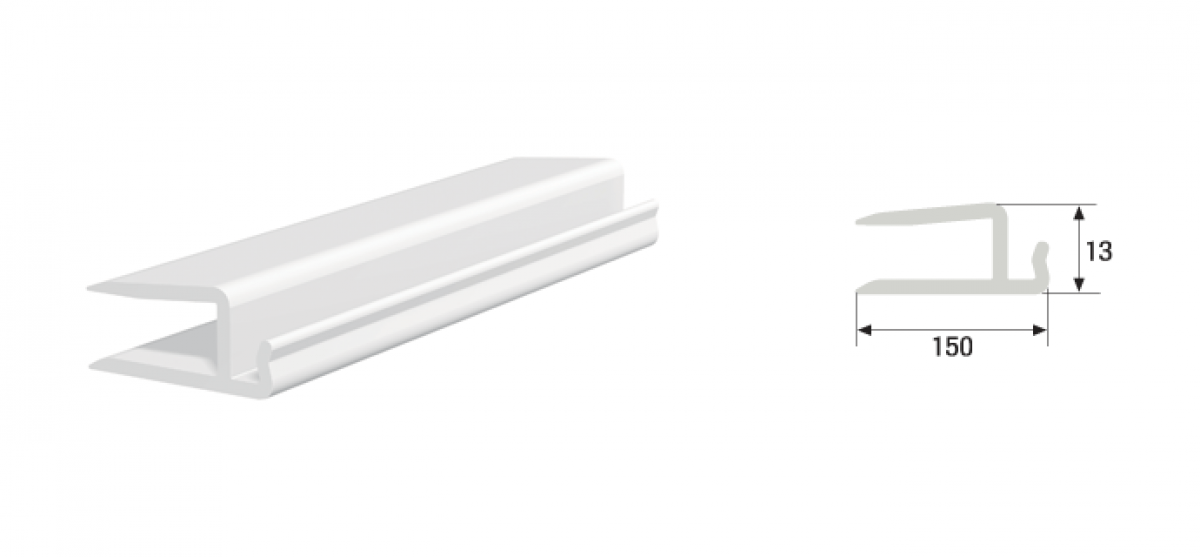

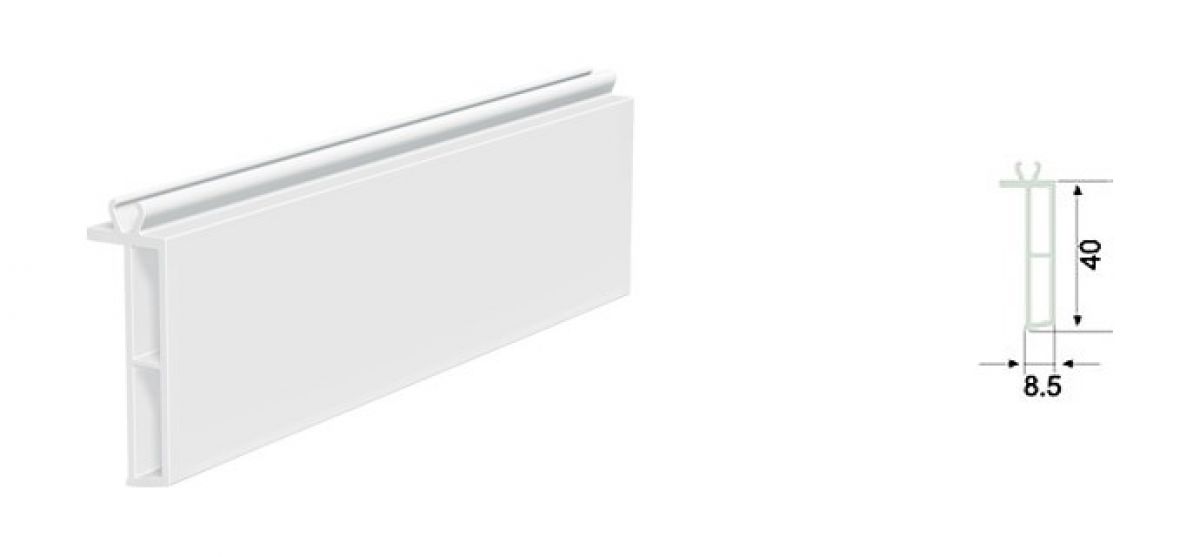

- Detail PVC Profiles

- Laminated PVC Profiles

- Components of PVC Door and Window Systems

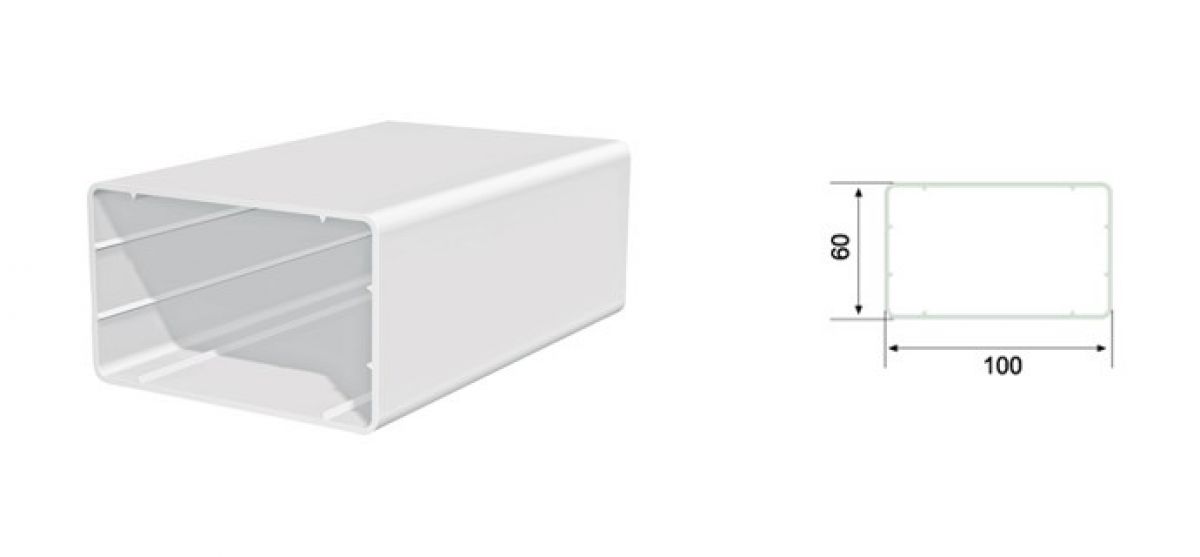

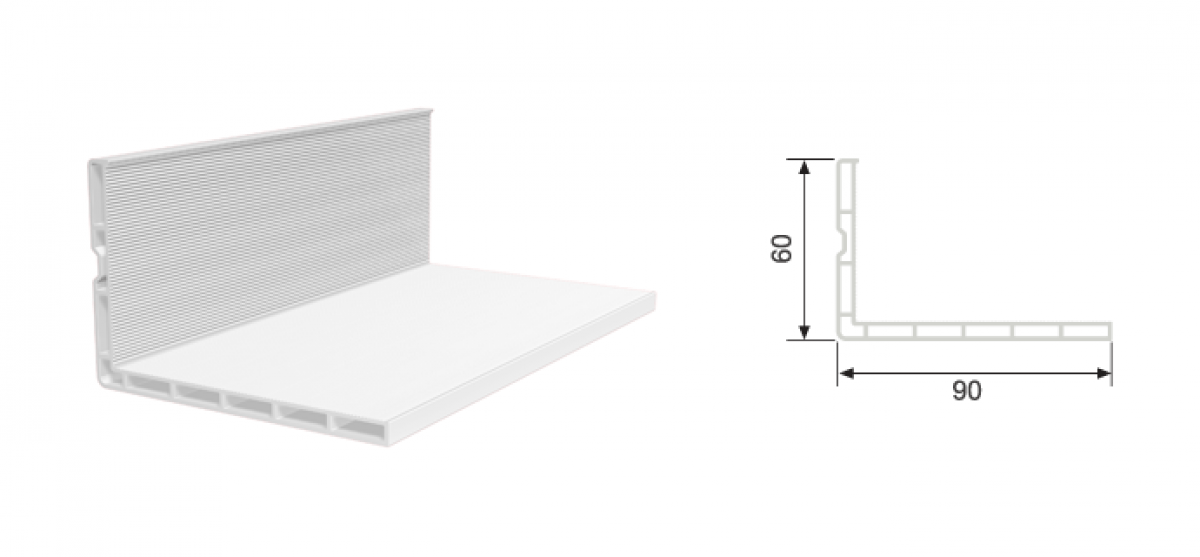

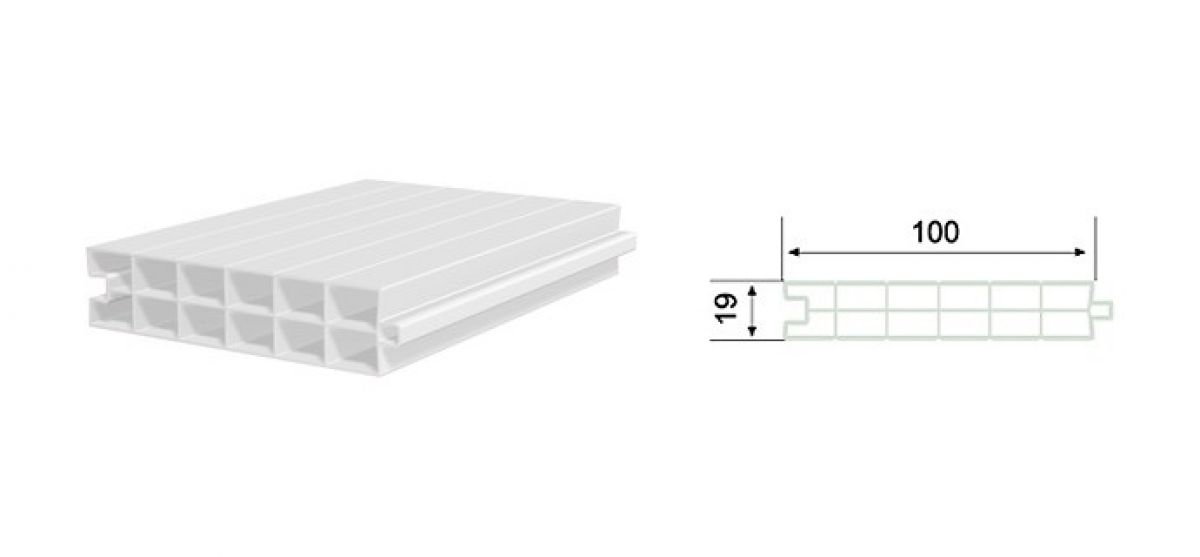

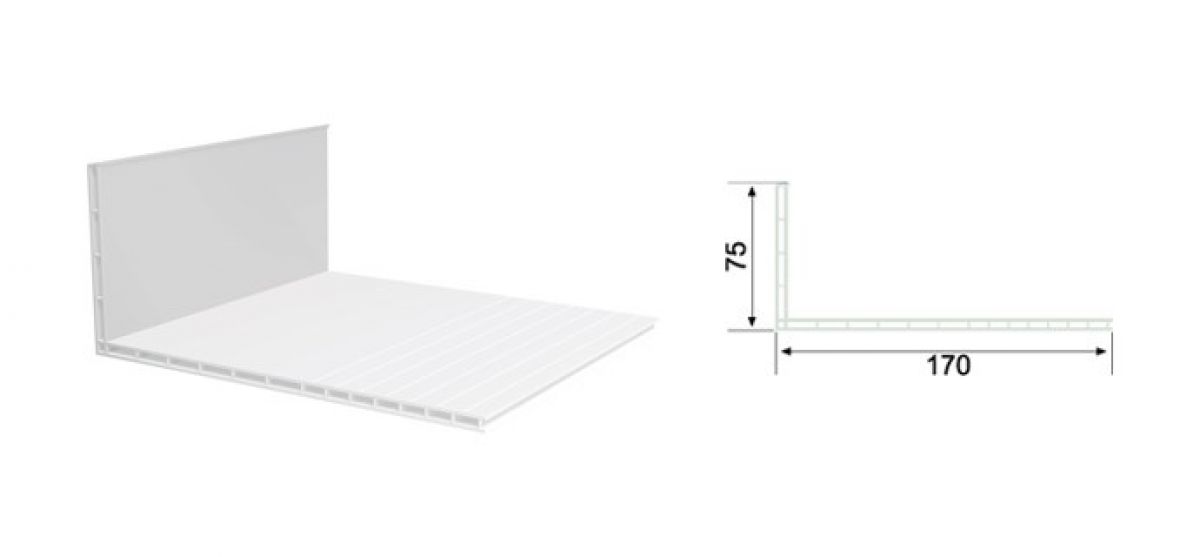

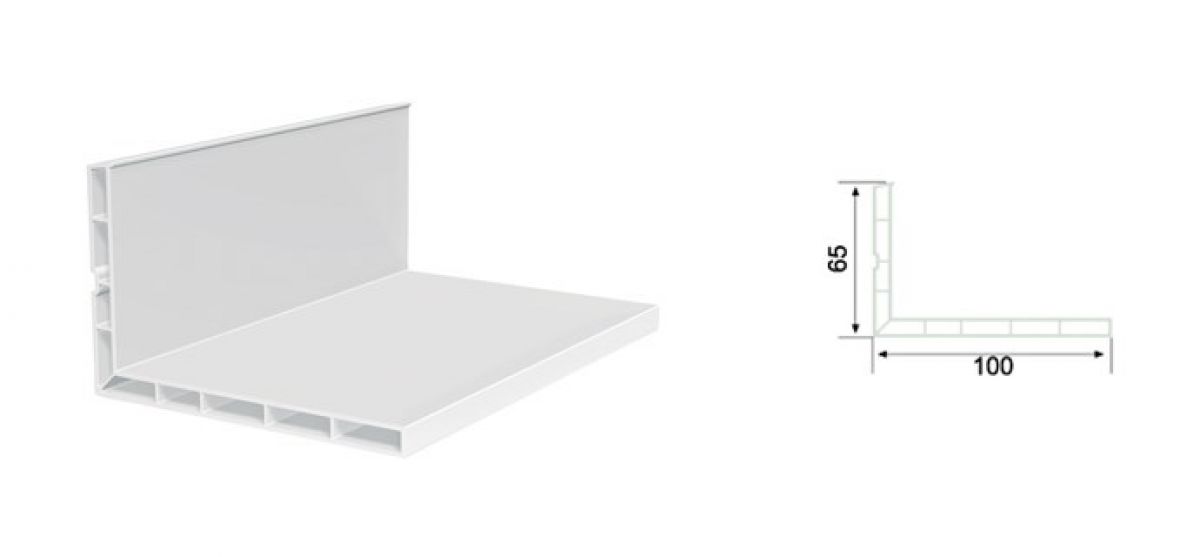

PVC detail profiles used in pvc door and window systems are the pvc profile types used in common in Fıratpen, Winhouse and Gedizpen brands and series which are the pvc window and door systems brands of Fırat.

Detail profiles do not have to be used in pvc door and window systems. Detail pvc plastic profile is preferred by the plastic window practitioner in order to solve possible problems in the application of pvc doors and windows or to meet the demands of the end consumer. It can be used to organize the architectural appearance of the window or to increase its performance, or it can be used to solve an existing application difficulty or problem.

The fact that they do not distinguish between series and brands within Fırat enables them to find more application areas. In addition, since the detail profiles of different manufacturers can differ in size and shape, the product diversity of the sector increases.

Another advantage of detail profiles is that they are not only used in PVC door and window systems. They are used in different sectors such as construction, agriculture sector (greenhouse etc.), pharmaceutical and chemical industry. Detail profiles provide ease of use in different areas due to their corrosion resistance, long life and superior insulation values.

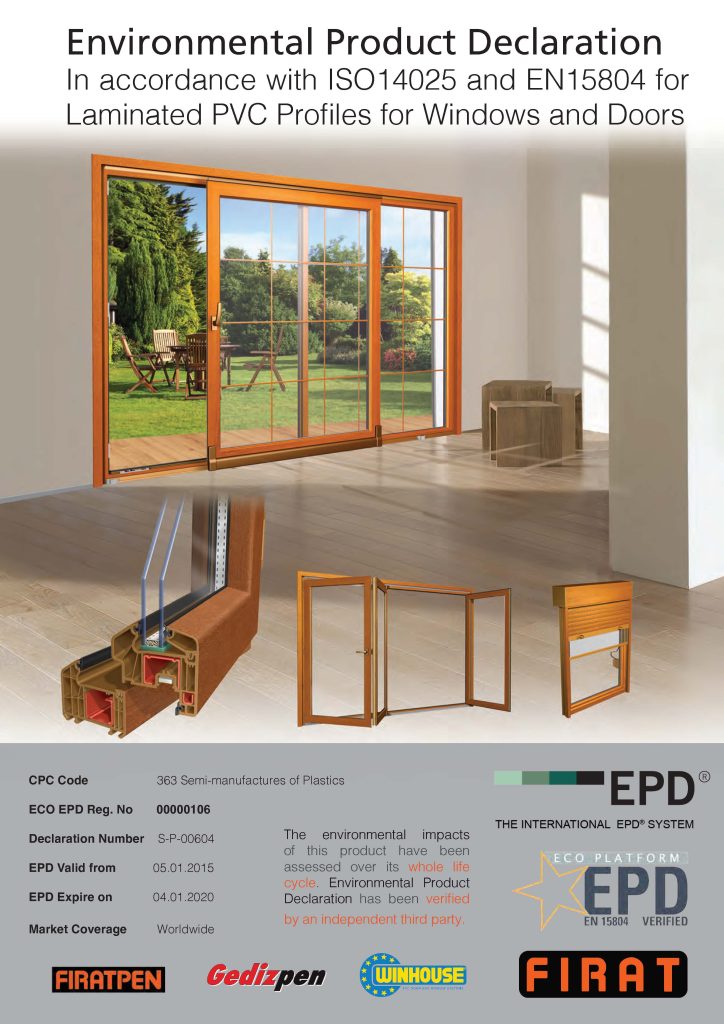

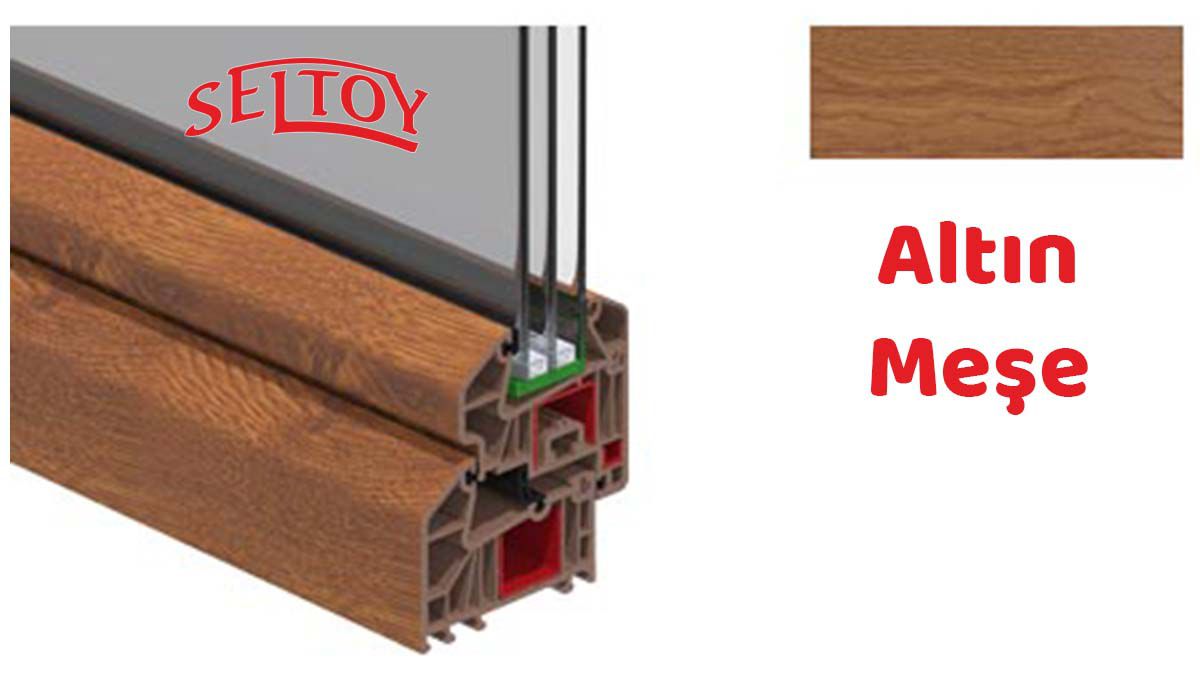

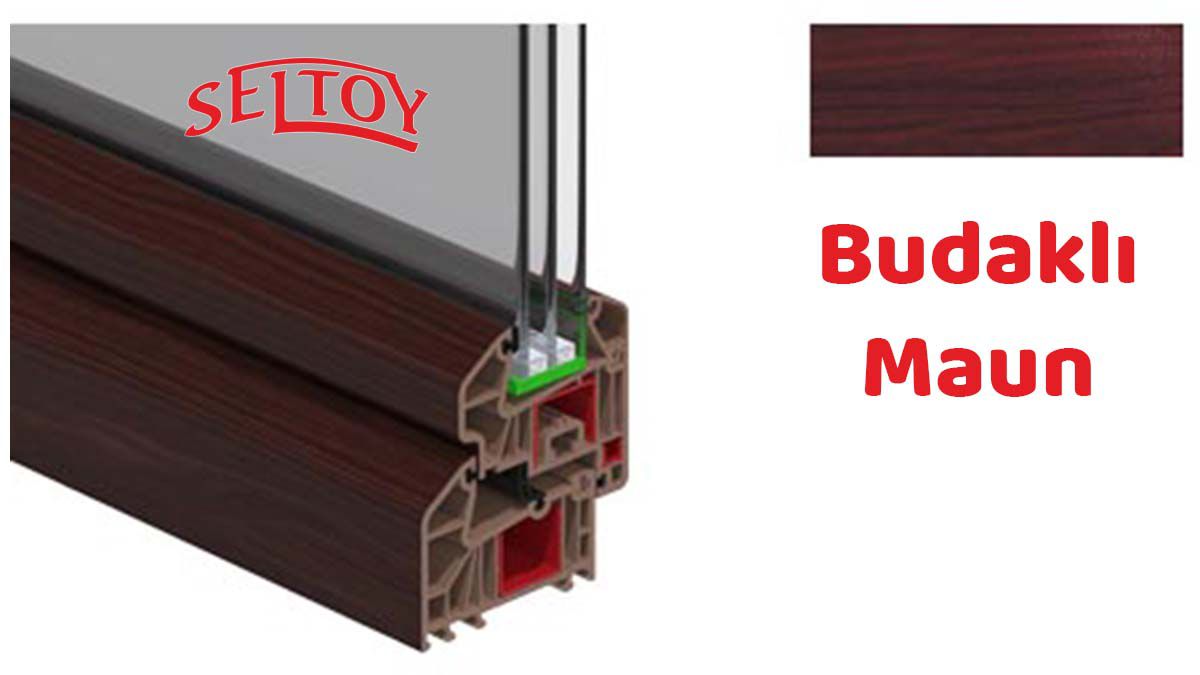

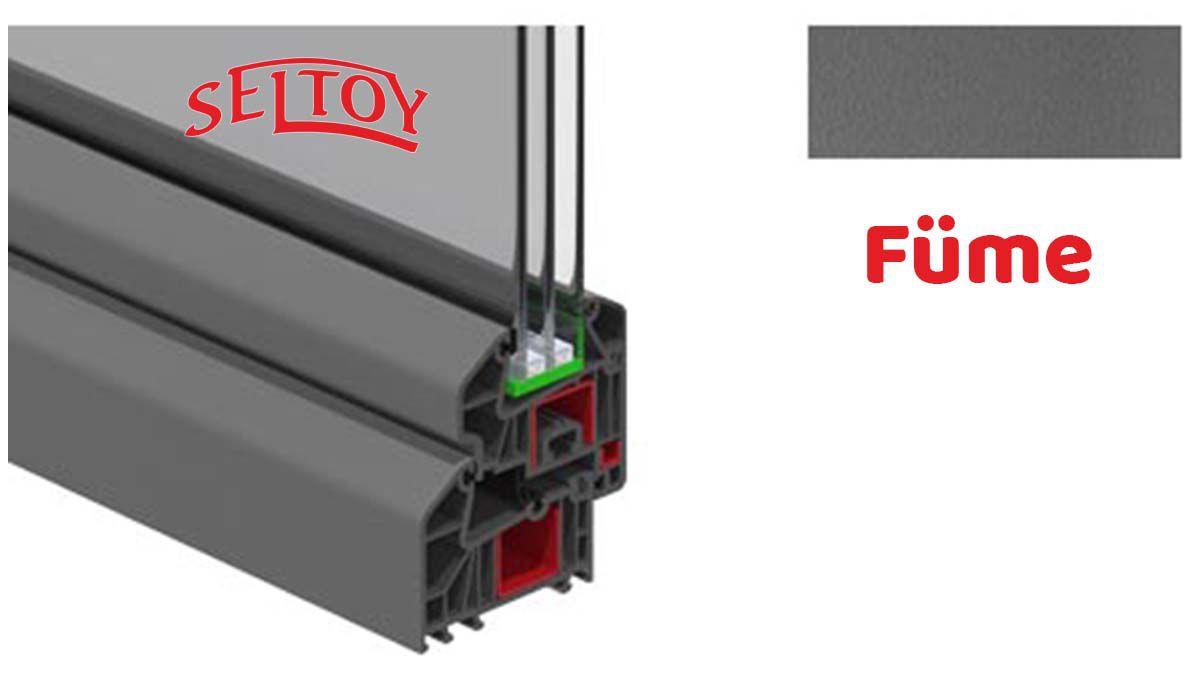

Fıratpen PVC Window and Door Systems with natural wood pattern coated with hot-melt lamination technique in accordance with international standards offer ideal solutions for your unique architectural and special decorative expectations with their rich coating options, aesthetic appearance and functionality.

We have added new colors to our Golden Oak, Gnarled Oak, Gnarled Mahogany, Cedar, Walnut, Gray and Anthracite wood patterned laminated options for your different tastes, projects and decoration alternatives. Your projects and houses are more colorful with our Antique Walnut, Snow White, Anodized Gray, Rustic Oak, Cream, Satin Gray, Midnight Blue, Dark Green, Eagle Black, Chestnut, Silver Gray, Juniper, Smoked, Metallic Gray and Hazelnut colors. You can contact our sales points and us via info@firat.com to meet our 21 different color options in total.

Fıratpen PVC Window and Door Systems with natural wood pattern coated with hot-melt lamination technique in accordance with RAL standards offer ideal solutions for your unique architectural and special decorative expectations with their rich coating options, aesthetic appearance and functionality.

We have added new colors to our Golden Oak, Gnarled Oak, Gnarled Mahogany, Cedar, Walnut, Grey and Anthracite wood patterned laminated options for your different tastes, projects and decoration alternatives. Your projects and homes are more colorful with our Antique Walnut, Snow White, Anodized Grey, Rustic Oak, Cream, Satin Grey, Midnight Blue, Dark Green, Eagle Black, Chestnut, Silver Grey, Juniper, Smoked, Metallic Grey and Hazelnut colors. You can contact our sales points and us to meet our 22 different color options in total.

Window Pattern Options Available in Our Stocks

When choosing between pvc door and window systems, it is necessary to consider 9 different factors that make up the systems.

All these factors affect the quality of pvc window systems more or less, but directly.

1. PVC Profile:

The first and most important condition for obtaining quality pvc joinery is to use quality pvc profiles. A pvc profile that fulfills the requirements of the standards, does not cause problems technically and during application, provides the required insulation values, and has effective and widely used quality certificates should be used. A pvc profile that meets these criteria is a prerequisite for a pvc joinery that meets the standards.

2. Support Sheet:

The biggest contribution of the support sheet to the pvc window is to form the skeleton and increase the strength. In addition, it has benefits such as preventing the structure from changing shape in the face of thermal changes, providing assembly strength and ease of connection, etc. The support sheet should be used in accordance with the shape of the PVC profile and it should not be neglected to apply a single piece of support sheet to each meter of each main profile possible in PVC joinery. Today, no other product has yet been developed that can replace metal support sheets one-to-one.

3. Gasket:

The most effective insulation material in PVC door and window systems is the gasket. Today, EPDM rubber and TPE plastic based seals are used.

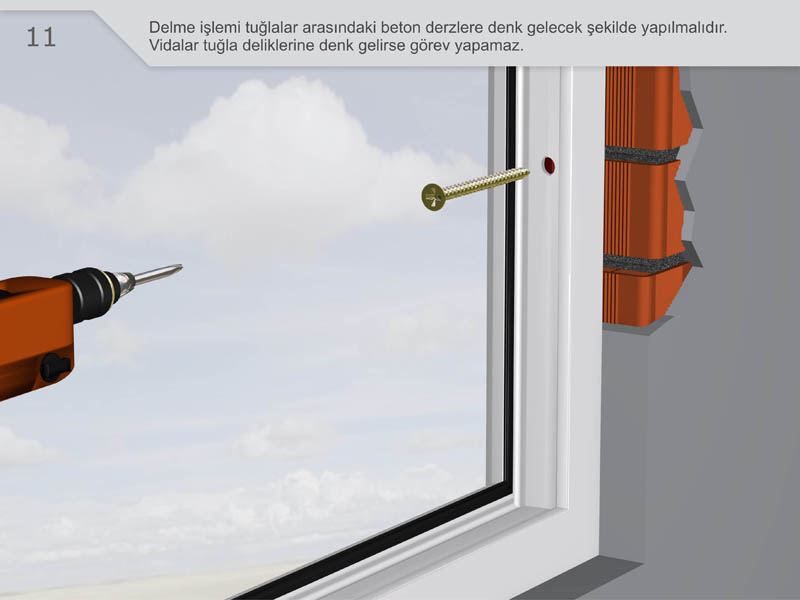

4. Connection Elements:

Fasteners in PVC door and window systems gain importance according to the geometric shapes of doors and windows and their location. In the fastener group consisting of screws and connection wedges, metal (zamak) materials with high abrasion resistance and coating that are not affected by climatic conditions and corrosive factors should be used.

5. Accessories:

They are the mechanisms that form the moving parts in PVC door and window systems and enable the movement to occur. Systems with quality certificates, high corrosion resistance and ease of use should be selected. Measurement criteria must be strictly followed.

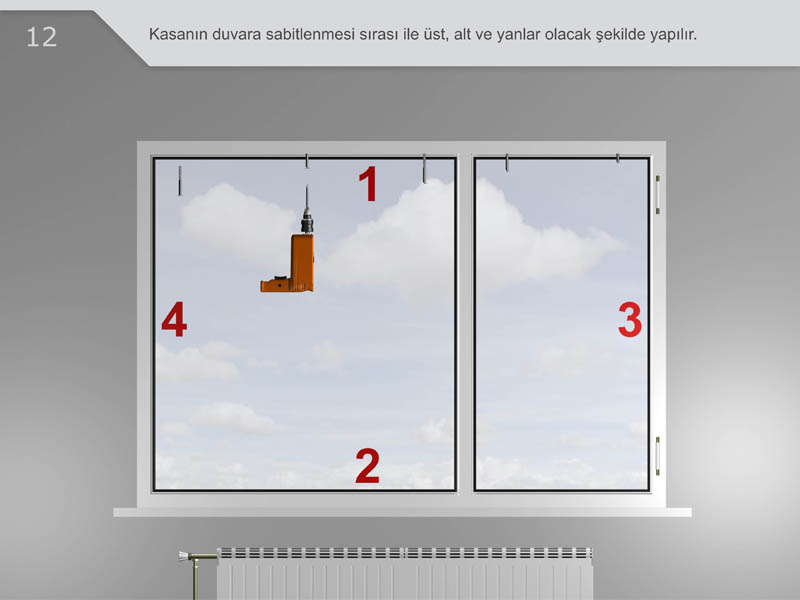

6. Assembly Materials.

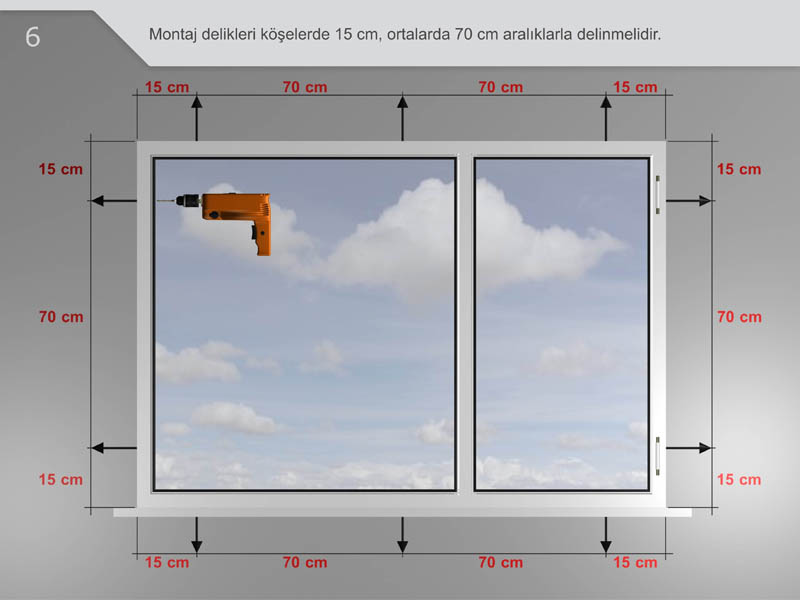

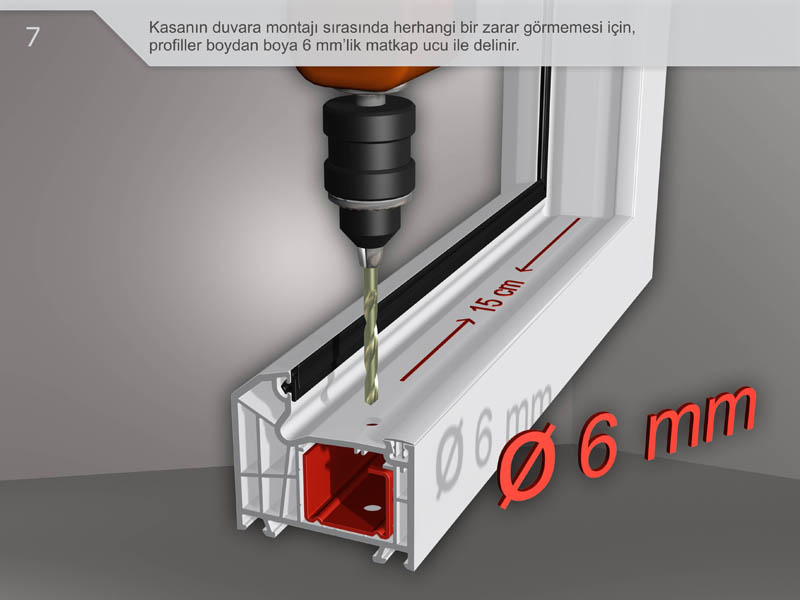

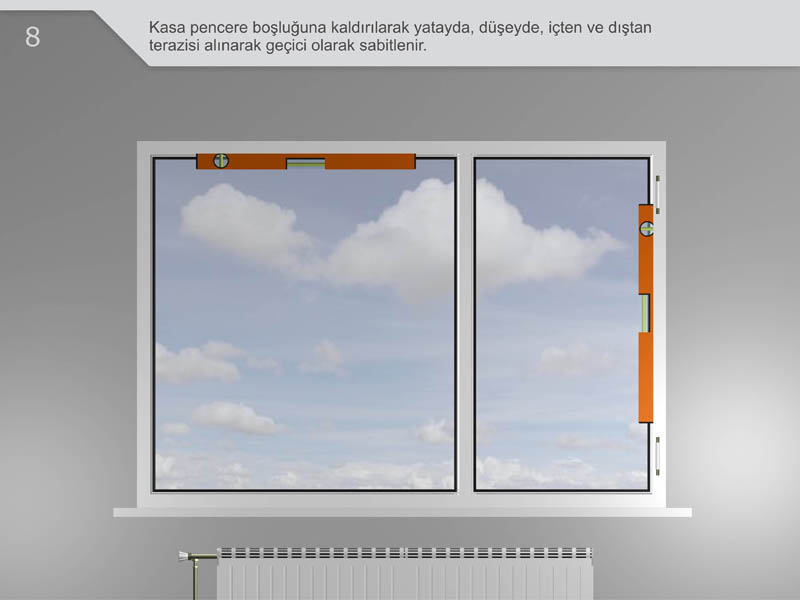

These are the materials that ensure that the pvc joinery is mounted on the wall in a healthy way and fulfills its function. Materials that are long-lasting and will not cause strength weakness over time should be selected.

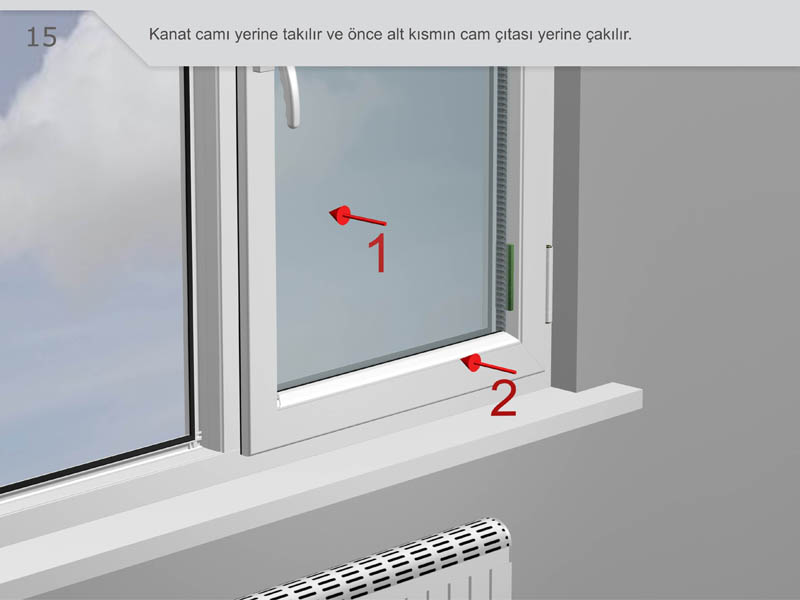

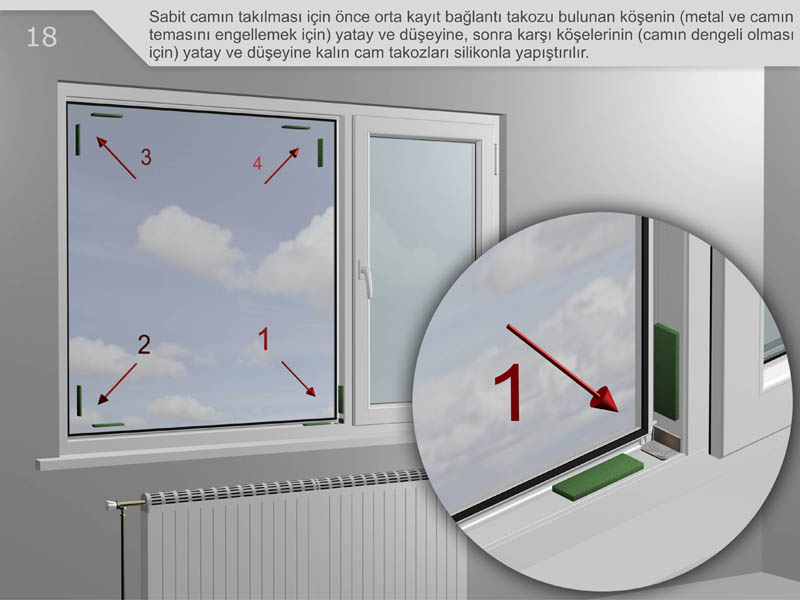

7. Glass:

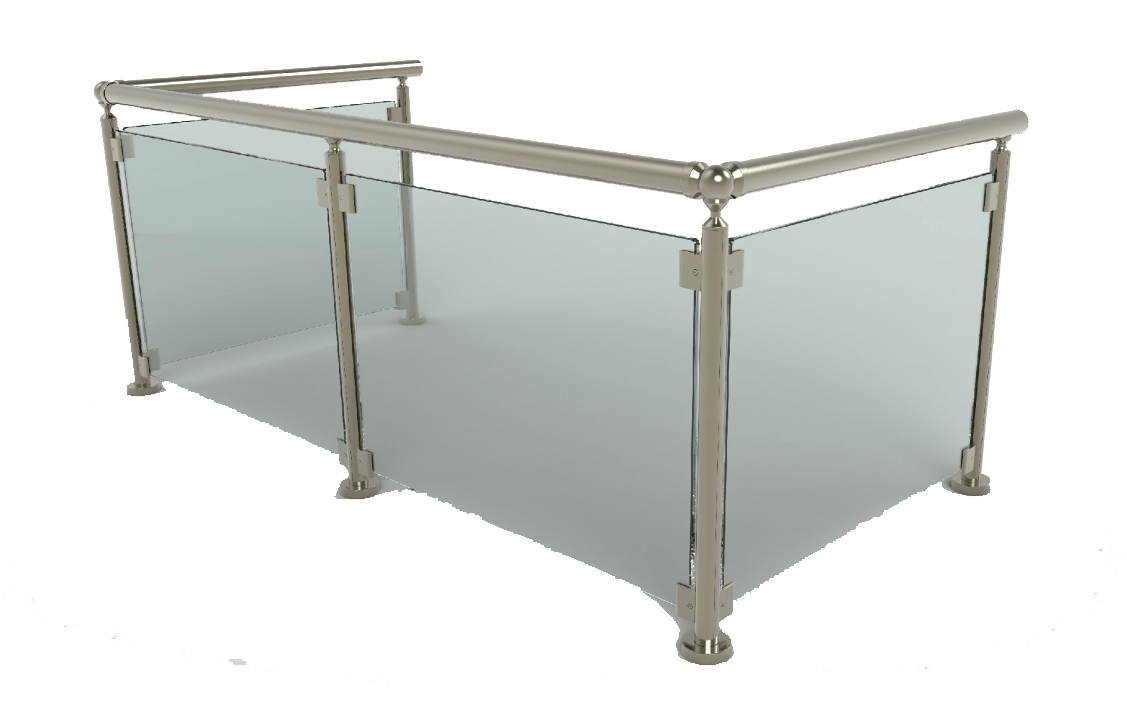

They constitute the largest part in terms of area in PVC door and window systems. It is the most effective element for heat and sound insulation. Glasses that do not disrupt the architectural structure, do not overload the system, help the movement to be completed in a healthy way and have quality certificates should be used. Especially in double glazing systems, the preference for “insulating glass synergy” and “insulating glass comfort” has increased as they provide heat and sound insulation.

8. Extras:

Extras are all other requests of the end consumer that add to PVC door and window systems, visual improvement and performance enhancement. It can be defined as moldings, paneling, carpentry, marble and special opening systems.

9. Labor:

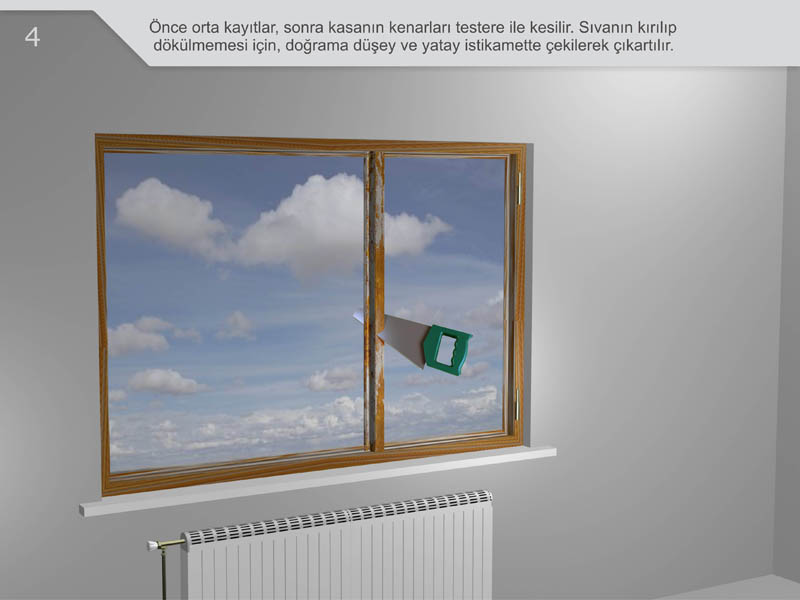

One of the biggest factors affecting the quality of pvc window systems is workmanship and assembly. It is possible to make a very bad pvc joinery – plastic window from a first class pvc profile, as well as a good pvc joinery from a bad pvc profile.