uninsulated door, window and showcase system

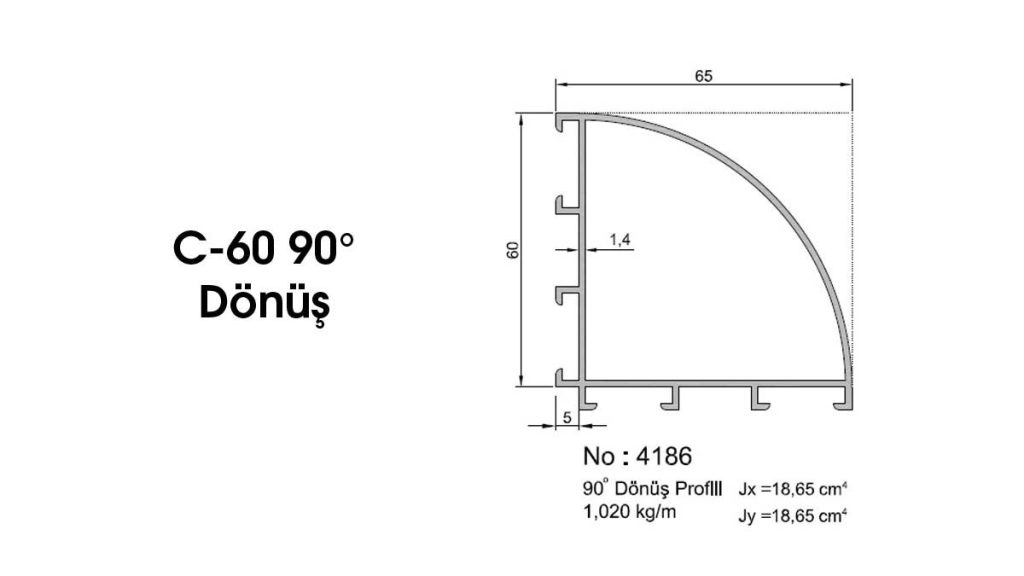

60 mm case thickness

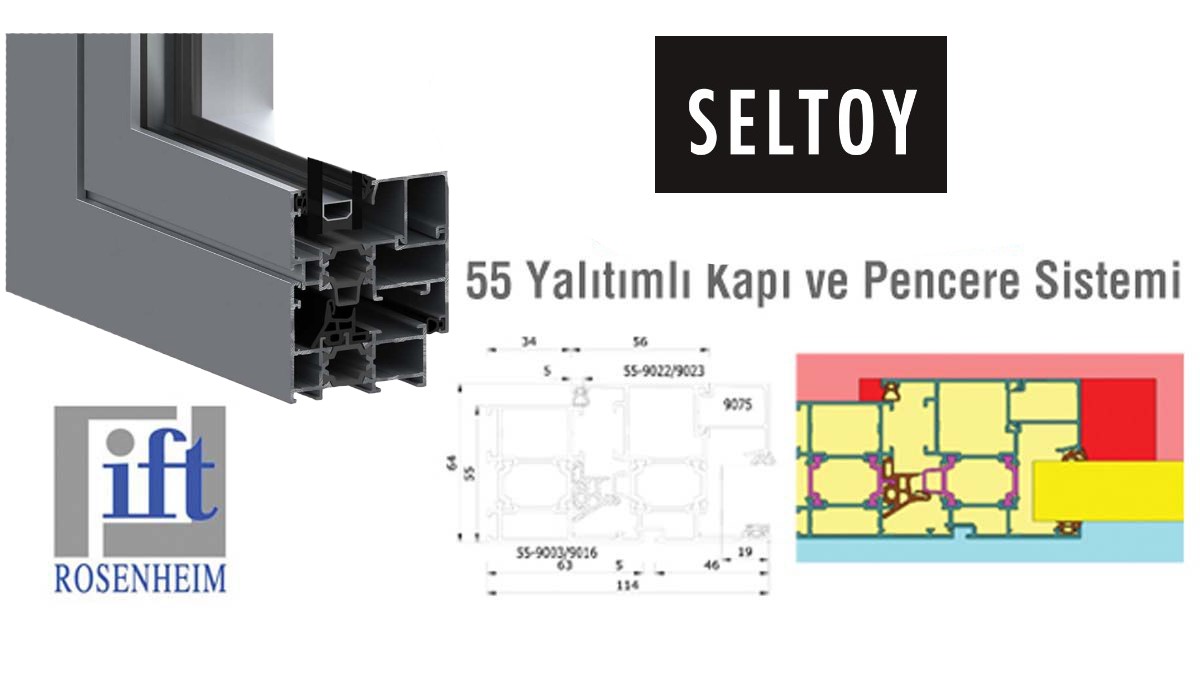

The Symbol of High Performance: EW-55

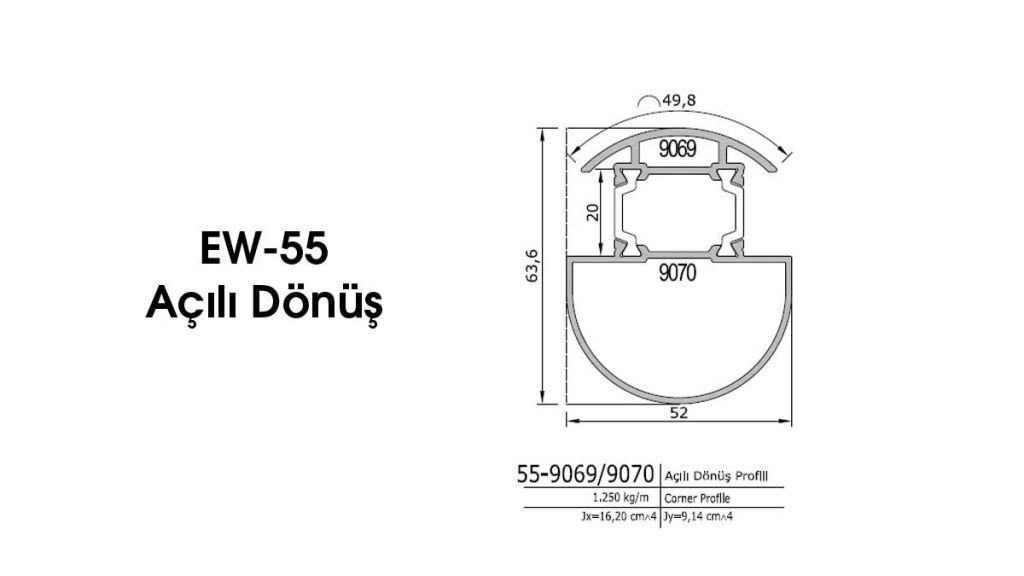

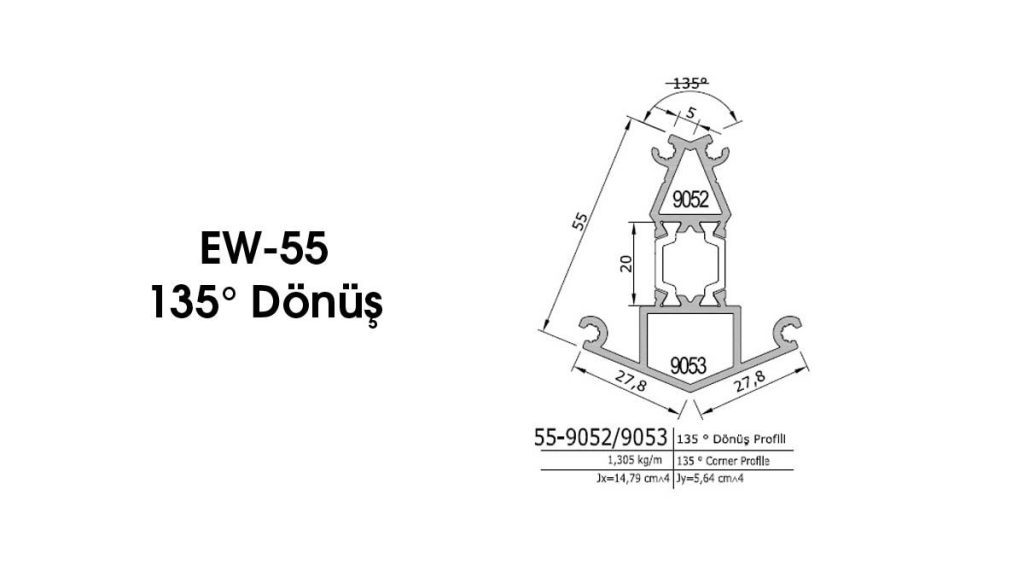

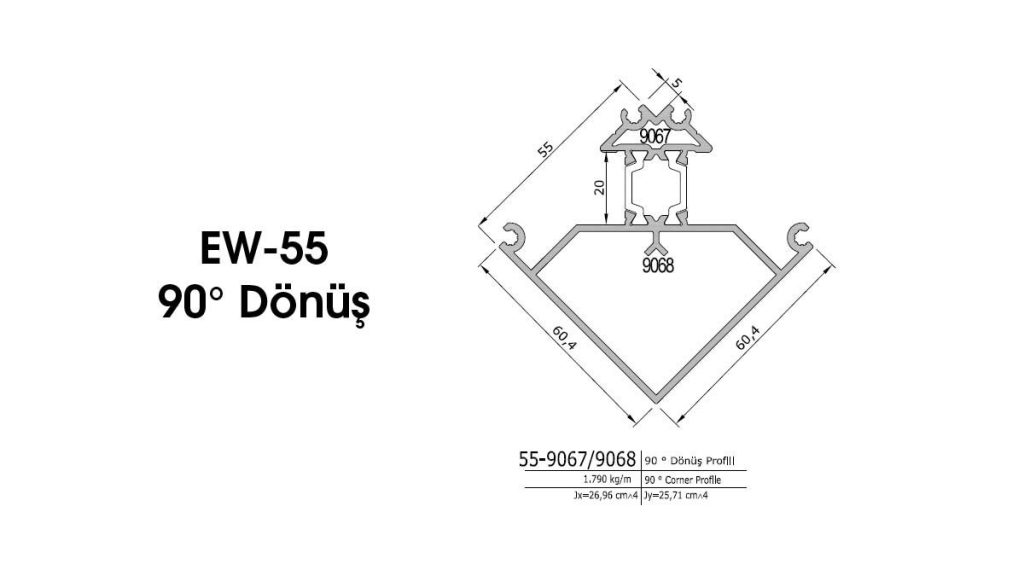

The prominent feature of the system is the pressure equalization principle at the frame-wing junction. According to this principle, no bini wick is used at the outermost part, and the pressure of the outer chamber and the external air environment is equalized, facilitating water discharge. Heat insulation and tightness are maximized thanks to the specially designed gasket with "double touch" feature in the middle part. Uw: 1.87 W/m2K (Window Heat Conduction Performance) Acoustic Performance: Rw (C, Ctr) ≤ 39 (-1; -3)dB, (Depends on glass thickness.) Water Permeability: Class ≥ 9A (EN 12208) Air Tightness: Class 4 (EN 12207) Wind Load Resistance: C2-C5 (EN 12210) System Depth (Sash) : 55mm -64mm Thermal Insulation Barrier Size : 20mm-14,8mm Applicable Glass Thickness : 4mm - 32mm In addition, the sash profile designed for PVC window mechanisms (double axis, pull sliding, folding system) with economical and easy application features is included in the system.

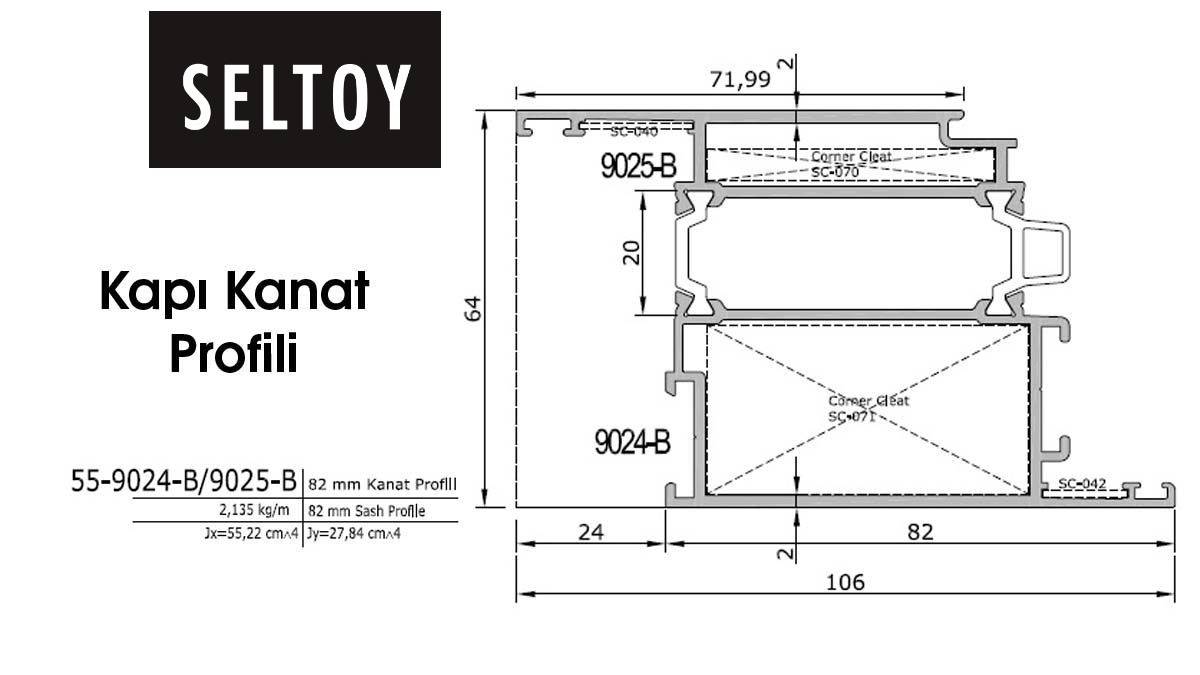

It is the most ideal solution with heat insulation especially for entrance doors in buildings. Easier application of mechanisms such as lock strikes, latches, hinges and both face-to-face design are its prominent features. Threshold solutions, inward and outward opening feature, compatibility with the register and safe of the window system make the system more functional. The system is aesthetically enriched with flat, oval and hidden sash designs considering different customer services.

EW 55

SYSTEM PERFORMANCE

Uf: 2.71 W/m2K (System Heat Conduction Performance)

Uw: 1.87 W/m2K (Window Heat Conduction Performance)

Acoustic Performance: Rw (C,Ctr)< 39(-1; -3) dB, (Depends on Glass Thickness.

Water Permeability: Class > 9A (EN 12208)

Air Impermeability: Class 4 (EN 12207)

Wind Load and resistance: C2-C5 (EN 12210)

TECHNICAL SPECIFICATIONS

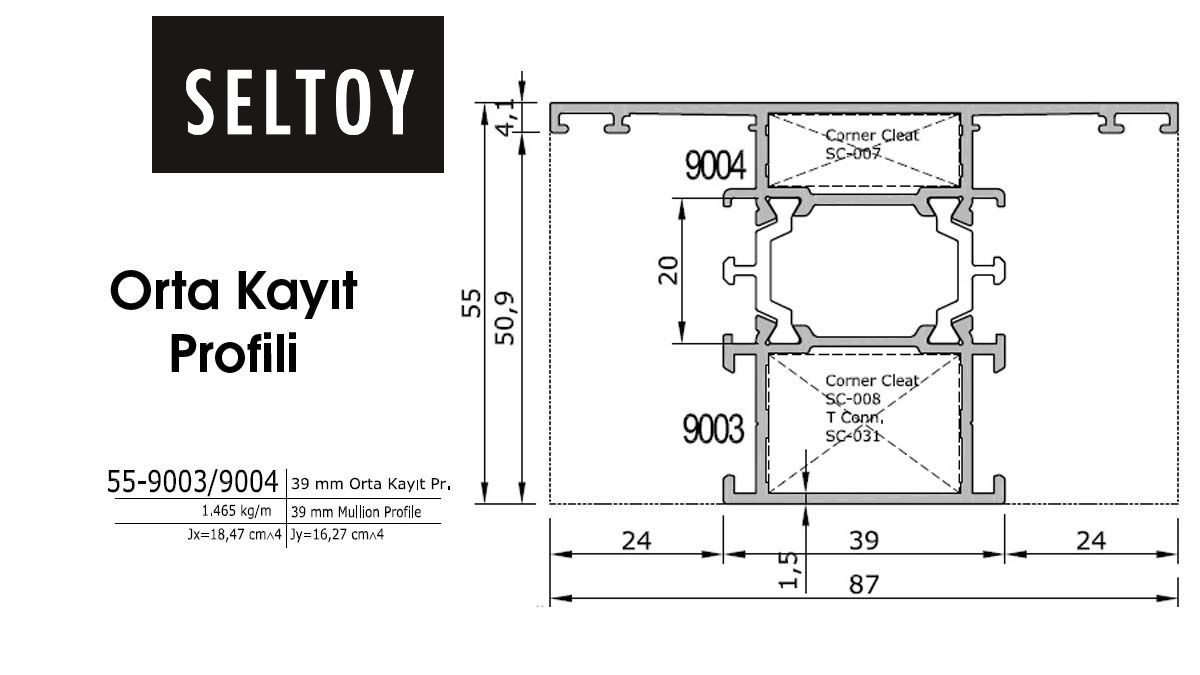

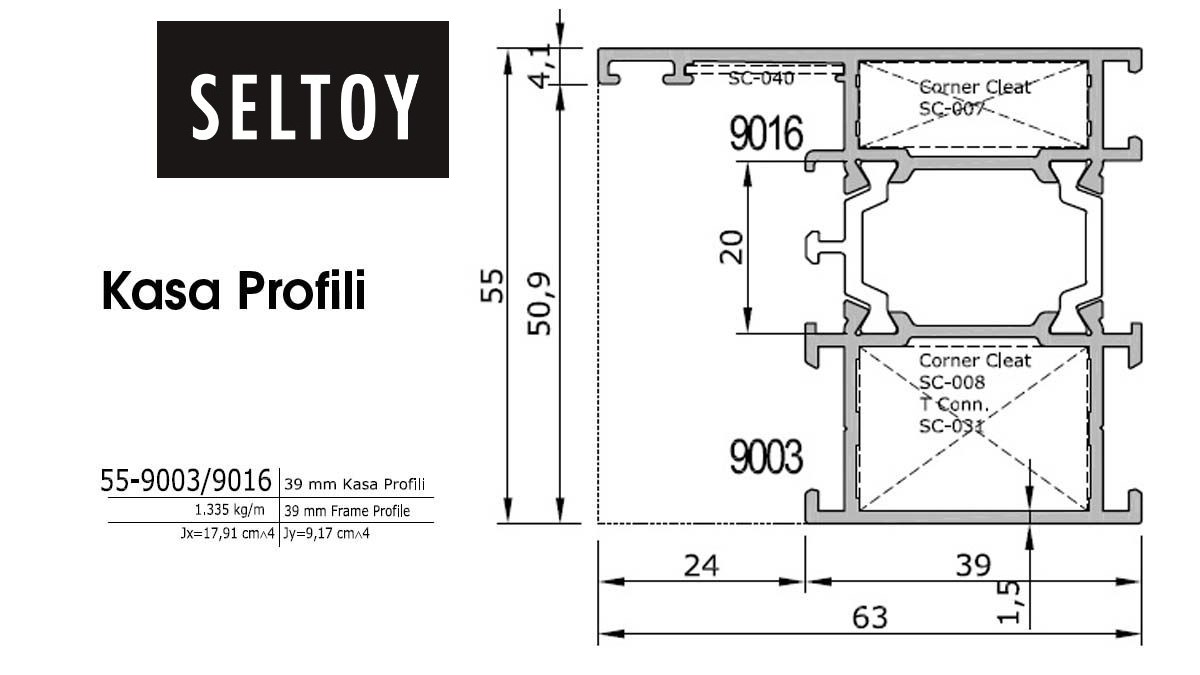

System Depth (Case) : 55mm

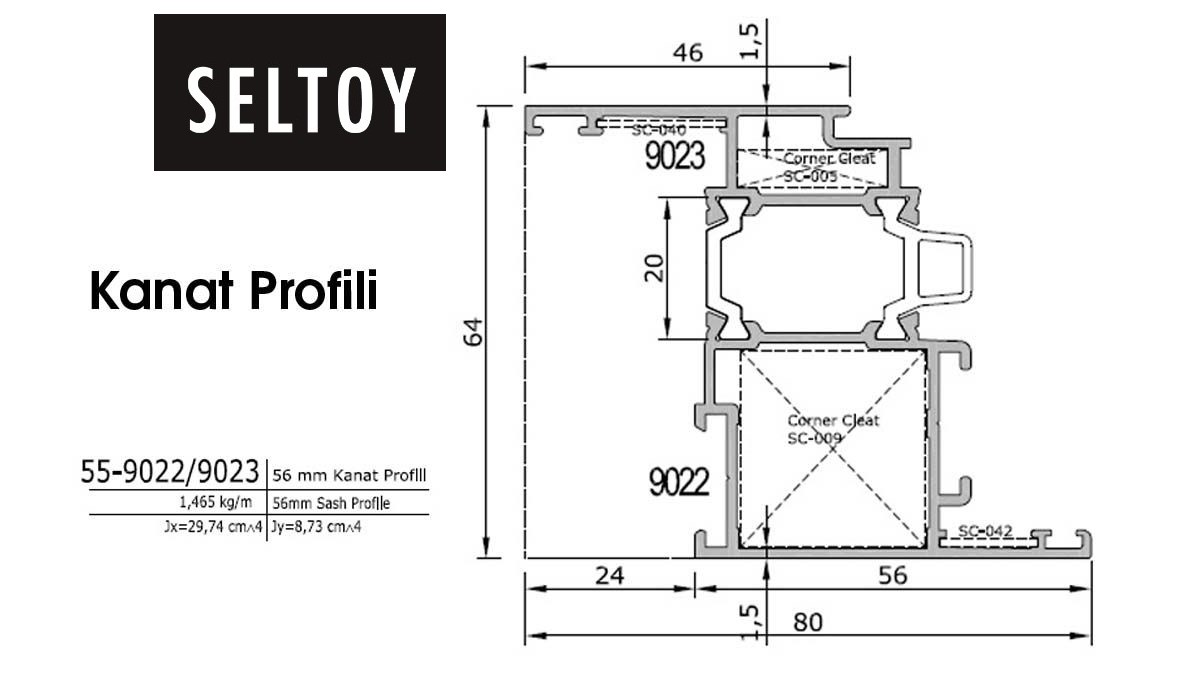

System Depth (Wing) : 64mm

Thermal insulation barrier length : 20mm System Depth (Safe) : 55mm

Applicable glass thickness : 4mm to 32mm

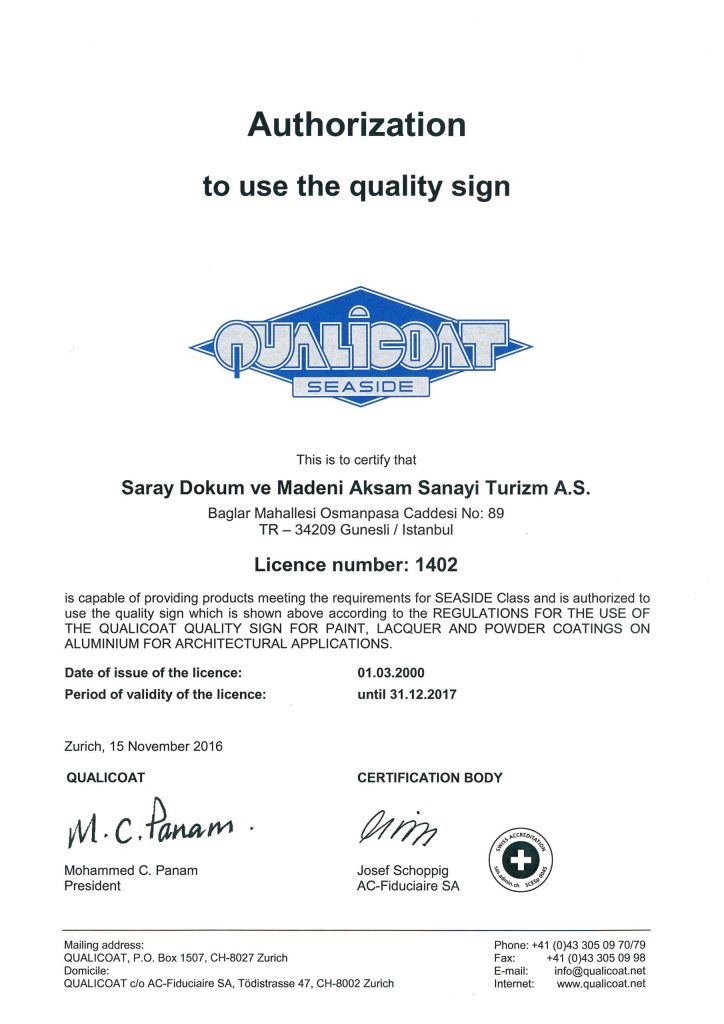

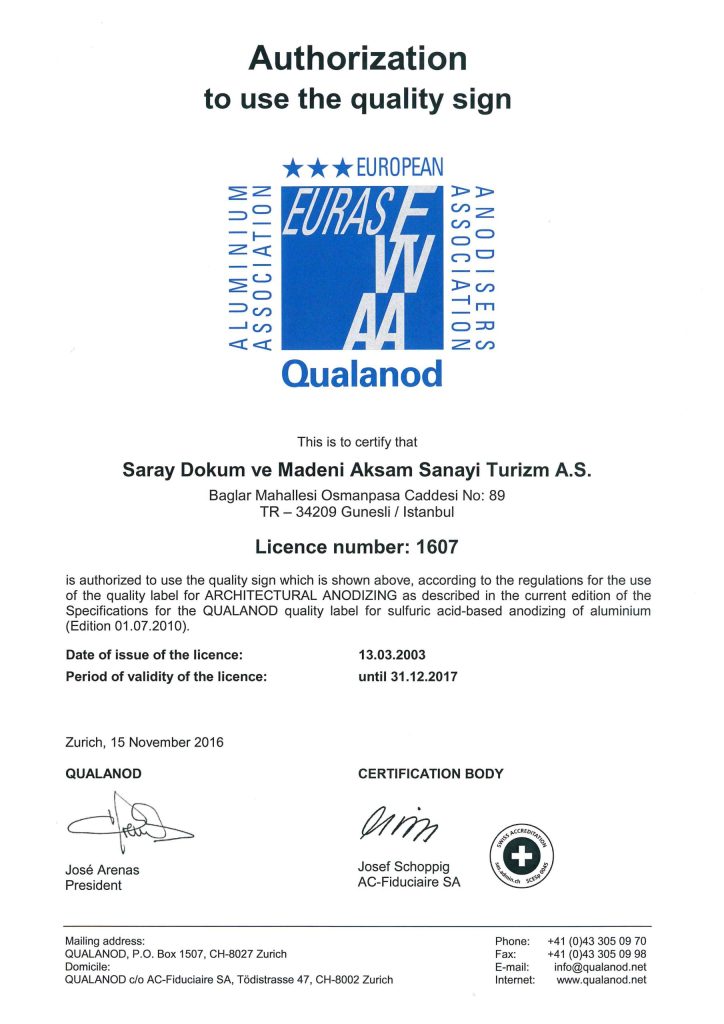

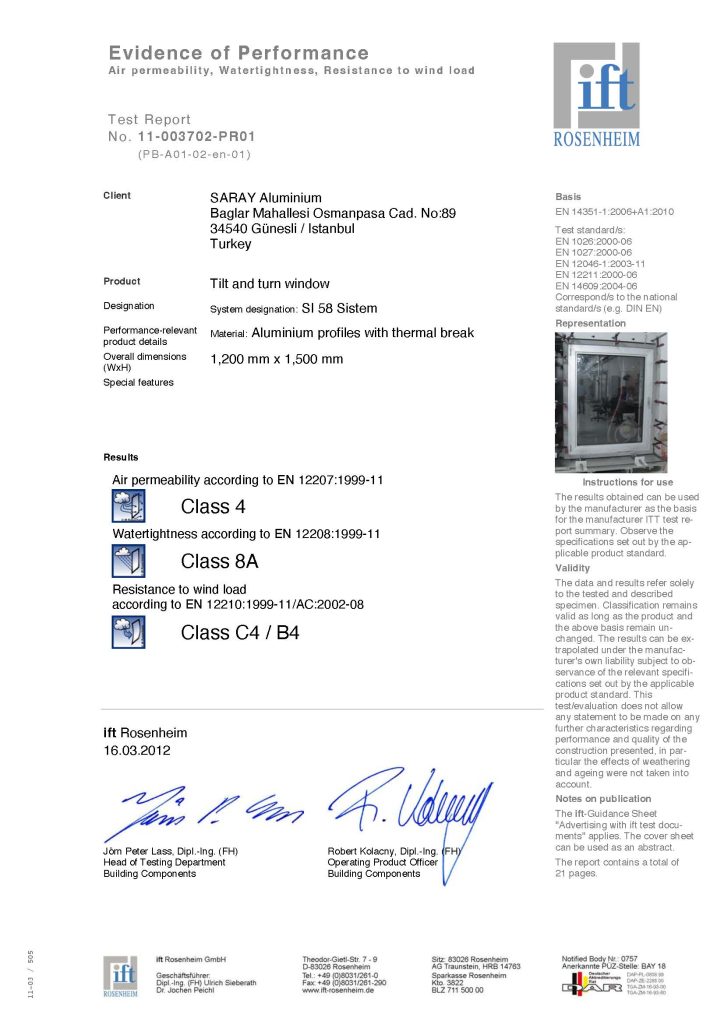

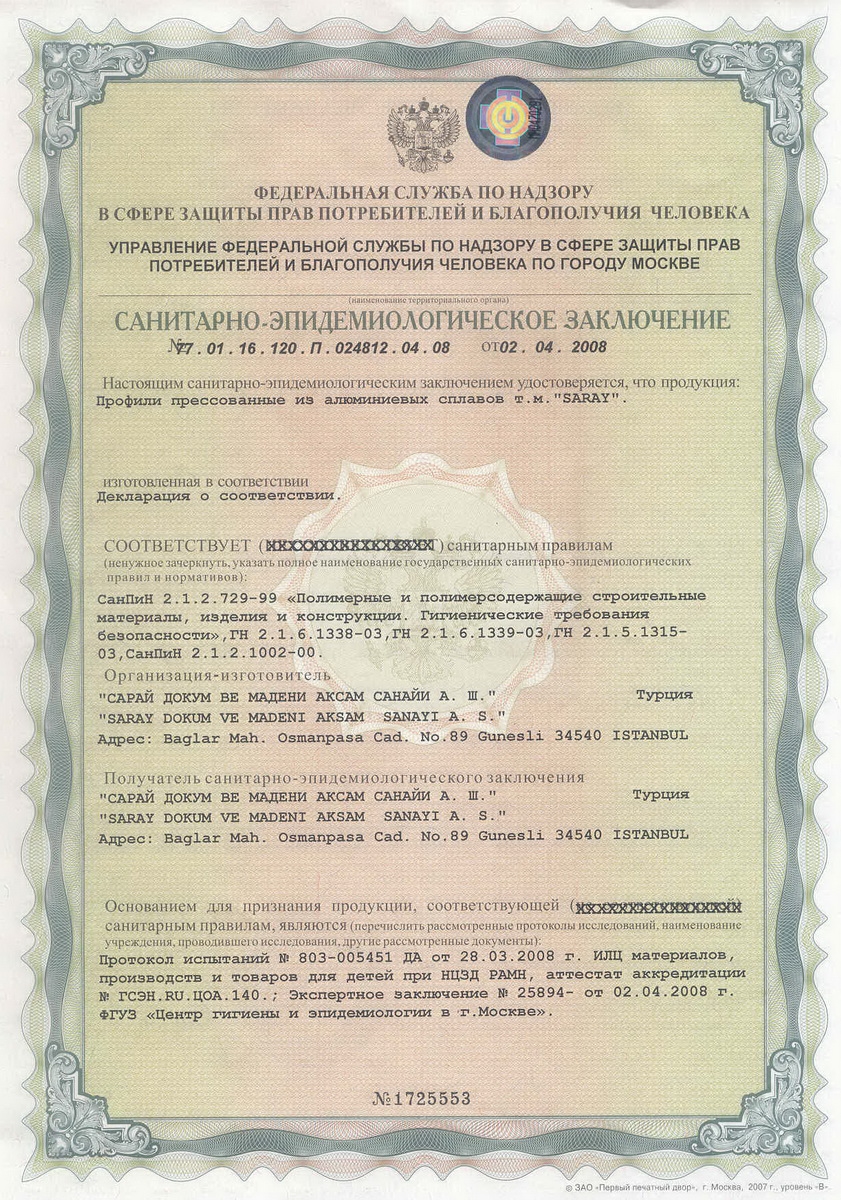

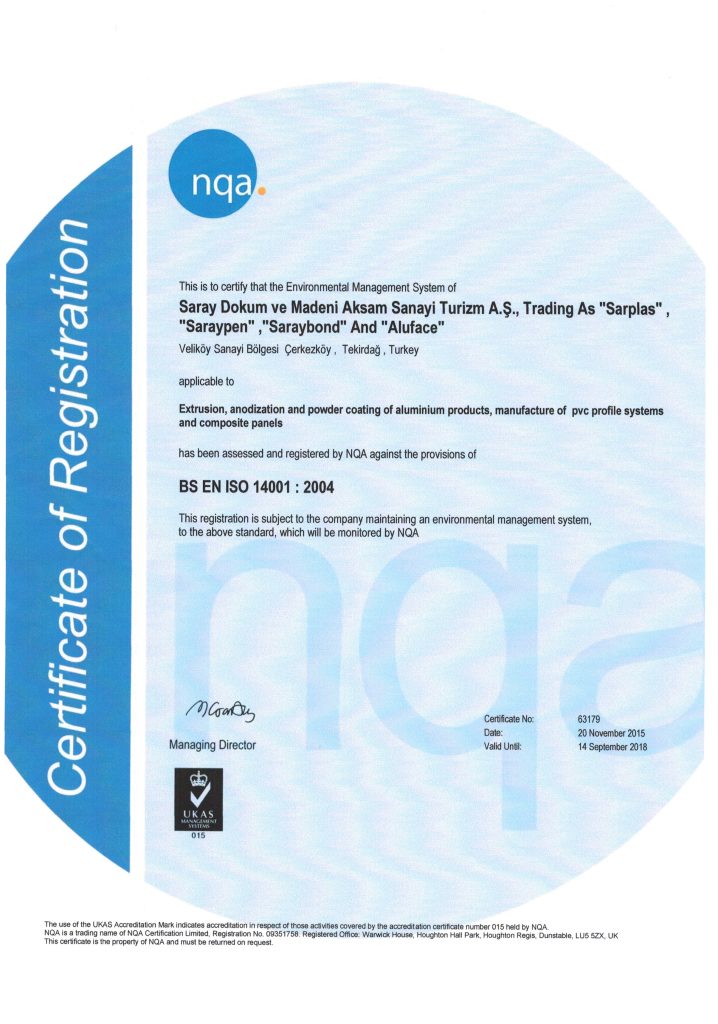

Certificates

- Certificates

- EPD Certificates

- Quality Certificates

- Environment & Occupational Health and Safety

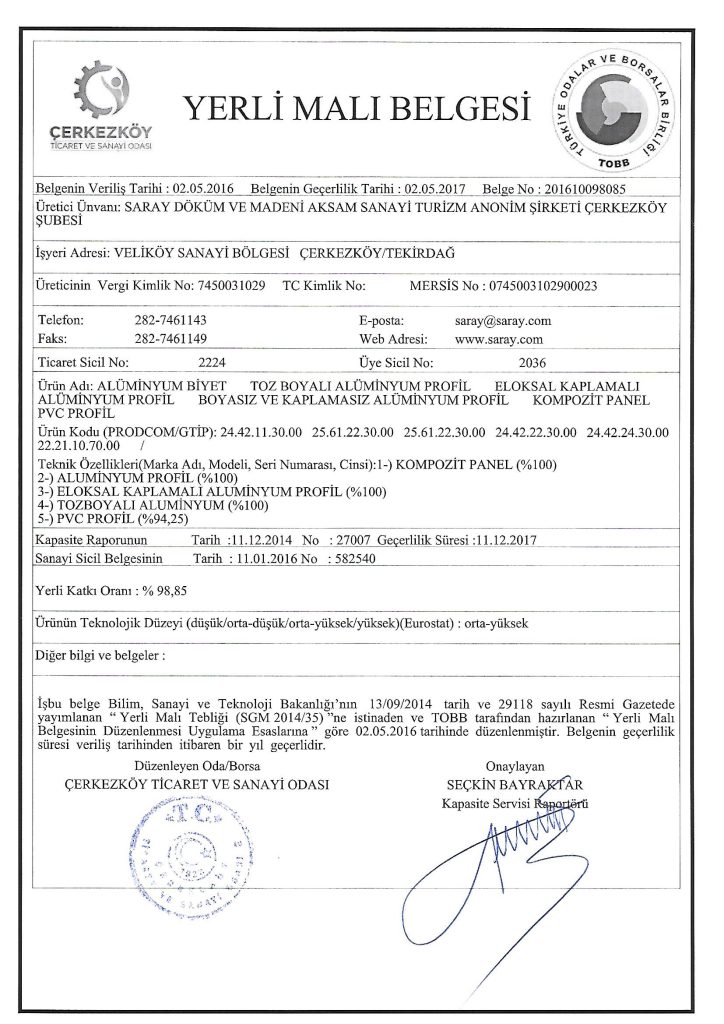

- Domestic Goods Certificate

SARAY Aluminum broke new ground in its sector by obtaining EPD certificates for its profile and panel products in compliance with EN 15804 European norm. EPD certificates are required by many green building evaluation and certification systems such as LEED, BREEAM, DGNB and ÇEDBİK.

SARAY Döküm ve Madeni Aksam Sanayi Turizm A.Ş. is breaking new ground with its innovations in the construction sector. Saray Aluminum has added the EN 15804 European norm-compliant “Environmental Product Declaration (EPD)” documents, which are published internationally through The International EPD System and valid in all markets, for PVC and Aluminum profile and Aluminum composite panel products, to its superior quality and standard certificates in the sector so far.

Saray, which has received EN 15804 – Sustainable Construction Materials norm-compliant EPD certificate for A2 class fireproof composite panels for the first time in Turkey, creates awareness in Europe and Turkey with its environmentally sensitive responsibility approach due to its position among the top 200 largest industrial companies in Turkey and its position at the forefront of the sector.

Saray, which produces in a total closed area of 90,000 square meters in its facilities in Istanbul and Çerkezköy, has successfully completed the EPD certificates obtained for A2, B1 and B2 fireproof class Aluminum Composite Panels (EPD Registration No: S-P-00834), Aluminum Extrusion Profile (EPD Registration No: S-P-00833), and PVC Profile (EPD Registration No: S-P-00832) products under the consultancy of Metsims Sustainability Consulting.

Saray Aluminum Composite Panels, Aluminum Extrusion Profiles and PVC Door & Window Profiles, each of which are innovative products in A2, B1 and B2 fireproof class according to TS standards, are among the most preferred brands in the construction sector with their high quality, quality certificates and EPD certificates.

EPDs are documents defined according to ISO 14025 that quantitatively evaluate and declare the environmental performance of a product according to predetermined categories (raw material extraction, energy use and efficiency; material and chemical content; emissions to air, water and soil; waste generation) on the basis of environmental impact parameters specified in the ISO 14040/44 LCA standard. This method of declaration, which takes into account the ecological footprint of economic activities within the scope of LCA and the various emissions and waste values that occur during the production process, is independently verified by international experts and is valid worldwide. EPD Certificates, known as Type III type environmental labeling, are required by many green building assessment and certification systems such as LEED, BREEAM, DGNB and ÇEDBİK while ensuring the dissemination of building products with environmental impact assessment.

Firmamızda, ISO 9001:2000 standardının gereklerini yerine getiren ve diğer yönetim fonksiyonları ile birlikte planlanan ve geliştirilen müşteri ihtiyaçlarını yerine getiren etkili ve yeterli bir Kalite Sistemi kurulmuş olup ISO 9001 Kalite Güvence Belgemiz bulunmaktadır. Böylece firmamız,;

- Bütün faaliyetlerini müşterilerinin memnuniyeti için yoğunlaştırmayı,

- Müşterilerine sağladığı ürünlerin ve hizmetlerin kalitesini sürekli olarak geliştirmeyi,

- Ürünleri zamanında teslim etmeyi,

- İsraf ve ziyanı ortadan kaldırarak ürünlerini ve hizmetlerini, en düşük maliyetle üretmeyi,

- Müşterilerinin ihtiyaçlarını karşılayacak nitelikte ürün üretmeyi esas olarak benimsemiştir.

Seltoy Ltd Şti bayisi olduğu Saraygrup, çevresel sorumluluklarının bilincinde; ürünün gerçekleştirilmesinden sevkiyata kadar geçen tüm aşamalarda, faaliyetlerinin çevre boyut ve etkilerini belirlemek ve bu boyutların ortaya çıkmasını önlemek amacıyla yöntemler uygulamaktadır. Saraygrup tüm faaliyetlerinin çevre kirliliğine neden olmaksızın yürütülmesi konusunda hassasiyet göstermektedir. Bu amaçla;

- Çevre ile ilgili tüm mevzuatlara uymayı,

- Doğal kaynakları optimum düzeyde kullanmayı,

- Kullanılan hammadde ve yardımcı maddelerde çevre kriterlerine uymayı,

- Kirliliğin önlenmesini, atıkların azaltılmasını ve maksimum geri dönüşümünü sağlamayı,

- Çalışanlarını çevre konusunda vereceği eğitimlerle bilinçlendirmeyi,

- Yeni yatırımlarda çevre faktörünü göz önünde bulundurmayı, ilke edinmiştir.

About Aluminum Window and Door Systems

- Aluminum Joinery Components

- Aluminum Extrusion Profile Specifications

- Why Aluminum Joinery

- Aluminum Joinery Features

- Aluminum Joinery Assembly Application

Properties sought in the materials used in Aluminum Joinery

The first is the quality of all the materials used in the window, especially the aluminum profiles and the plastic insulation profiles used to prevent the profiles from conducting heat between the internal and external environments.

Aluminum profiles

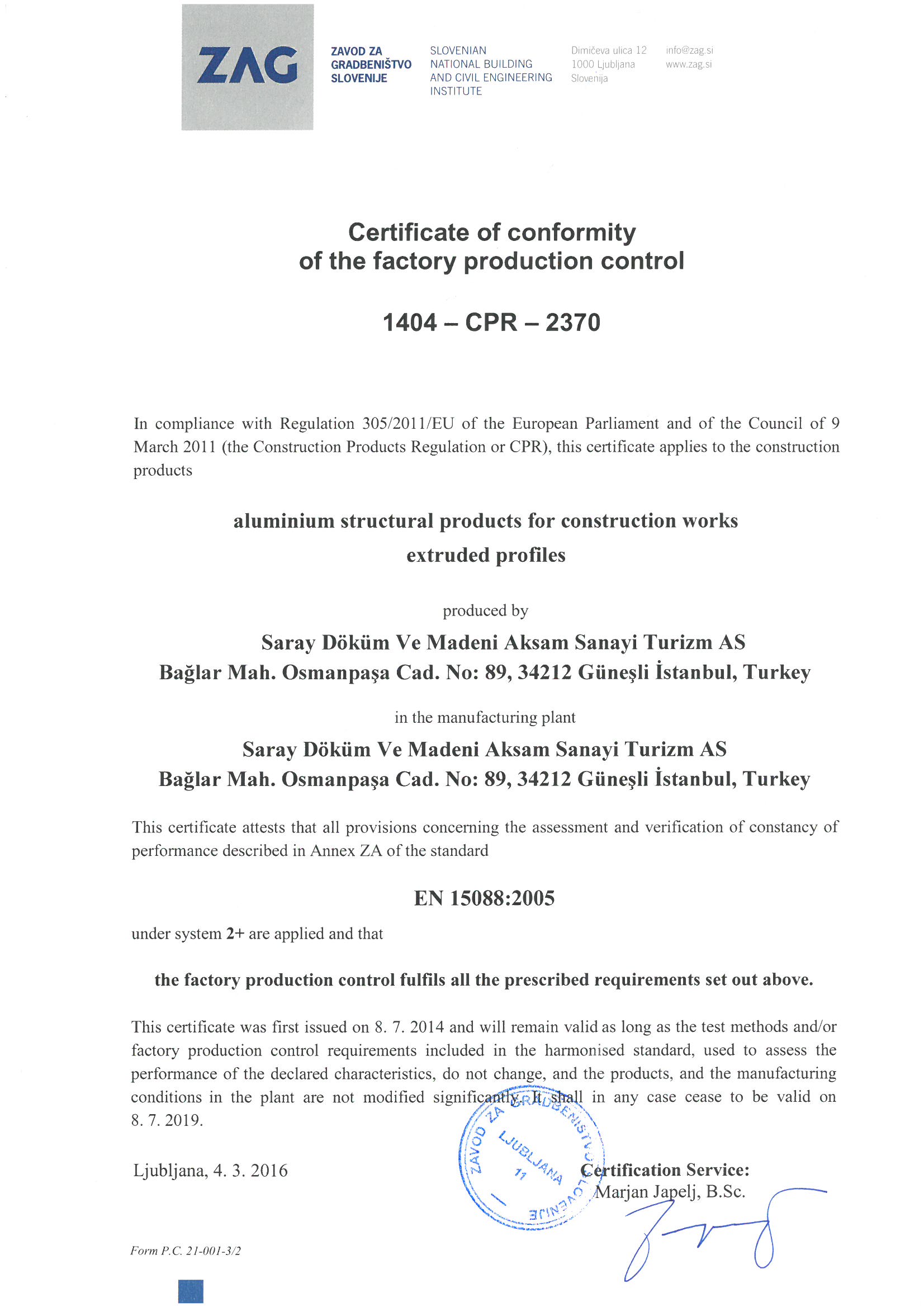

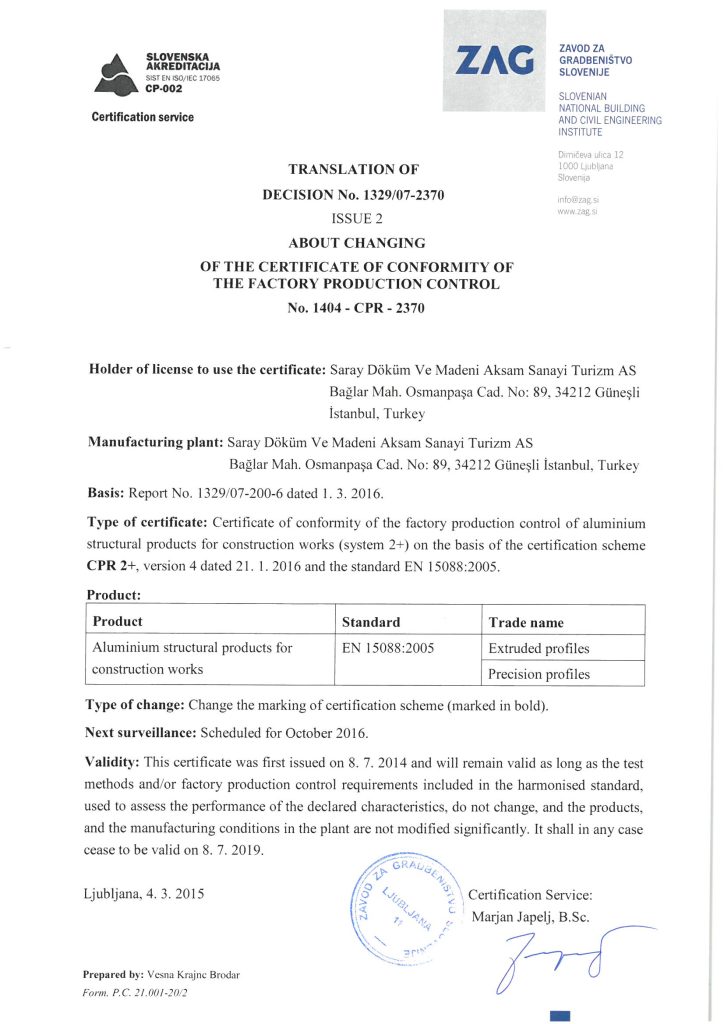

A Certificate of Conformity to Turkish Standards related to TS EN 12020-1 and TS EN 12020-2 standards must be sought from the aluminum profile manufacturer. This certificate is issued for EN AW 6060 and EN AW 6063 alloy groups and for extrusion profiles with and without thermal barrier from precision alloyed aluminum material.

TS EN 12020-1 (02.03.2010) Aluminum and aluminum alloys – Extruded precision profiles made of most aw- 6060 and most aw- 6063 alloys

Technical inspection and delivery conditions

TS EN 12020-2 (02.03.2010) This standard covers the size and shape tolerances of precision profiles extruded from EN AW-6060 and EN AW-6063 alloys with and without thermal barrier.

The EN 15088 standard for the aluminum sector includes general requirements for aluminum and aluminum alloys to be used in the construction industry. EN 15088 is for manufacturers of aluminum and aluminum alloys (profiles, etc.) for use in construction works. Conformity with the Construction Products Directive (CPD) and consequently CE marking is a legal obligation in accordance with Law No. 4703 to offer the product to the European and Turkish market.

The wall thickness of the profiles to be used in joinery should be evaluated in terms of wind and bearing loads, but frame, middle register, adapter and sash profiles thinner than 1.8mm are not recommended as they cannot hold healthy screws.

For aluminum profiles used in joinery, 6060-T5 or 6063-T5 (alloy-heat treatment) should be used.

T5: It means cooled and artificially aged after hot forming process.

Accordingly, the profiles are cooled after the extrusion process and then put into artificial aging (thermal) furnaces.

Features to be sought in heat insulated profiles

Heat insulation barriers made of polyamide material with 25% glass fiber reinforcement should be used in heat insulated profiles. In the Turkish market, polyamide is generally used only when necessary (because it can enter the paint oven) and although PVC barriers are preferred because they are cheaper, polyamide thermal barriers should be preferred.

Although different materials are used as thermal insulation barriers, polyamide thermal insulation barriers are the most suitable material to be used as thermal insulation barriers since their thermal elongation coefficients are the same as aluminum and their mechanical values are high. Polyamide thermal insulation barriers are 25% glass fiber reinforced as standard.

It is recommended that thermal insulation barriers should be at least 18mm. Would you like to learn how the choice of thermal insulation barrier affects thermal insulation?

Features to be sought in heat insulated profiles

Heat insulation barriers made of polyamide material with 25% glass fiber reinforcement should be used in heat insulated profiles. In the Turkish market, polyamide is generally used only when necessary (because it can enter the paint oven) and although PVC barriers are preferred because they are cheaper, polyamide thermal barriers should be preferred.

Although different materials are used as thermal insulation barriers, polyamide thermal insulation barriers are the most suitable material to be used as thermal insulation barriers since their thermal elongation coefficients are the same as aluminum and their mechanical values are high. Polyamide thermal insulation barriers are 25% glass fiber reinforced as standard.

It is recommended that thermal insulation barriers should be at least 18mm. Would you like to learn how the choice of thermal insulation barrier affects thermal insulation?

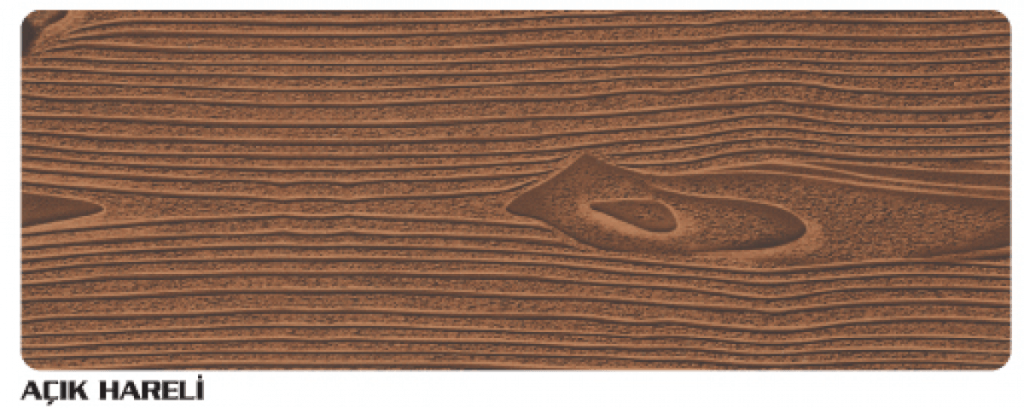

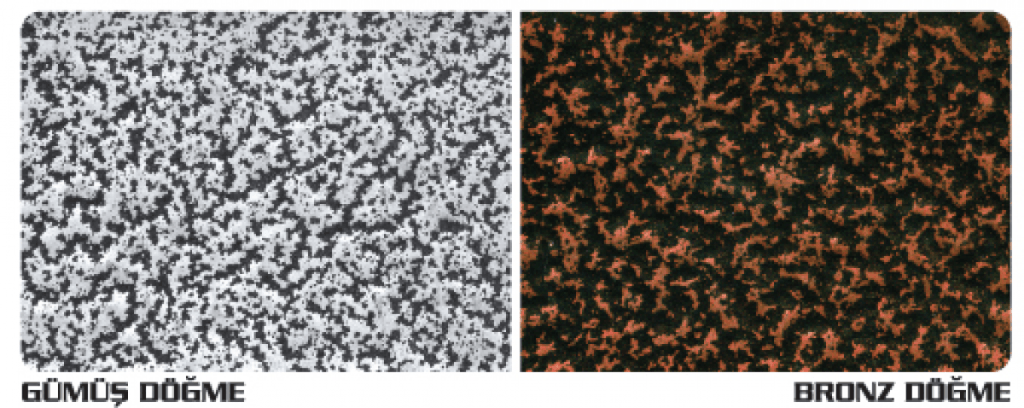

Surface treatments (Anodizing, Electrostatic Powder Coating, Wood Pattern Coating)

Profiles used in architectural aluminum window, door and facade systems are produced raw and then anodized, electrostatic powder coating or wood pattern coating process is applied to obtain the desired surface appearance.

Anodized:

TS 4922 (27.10.1986) Surface treatment of metallic materials – Anodic oxidation (anodizing) of aluminum and formable aluminum alloys, technical specifications

Qualanod Quality Certificate used in European countries should be sought. Qualanod is a comprehensive standard for sulfuric acid based anodizing of aluminum and many manufacturers in Turkey have this certificate. Manufacturers with this certificate are regularly audited.

Electrostatic Powder Coating:

Qualicoat Quality Certificate used in European countries must be sought.

Complementary parts

For hinges (TS 4922), EPDM seals and other complementary parts, the relevant standards must be observed. Corner wedges and serge connections must be fully assembled.

Metals play an important role in the development of civilization. Few metals play as important a role in this development process as aluminum. With its unique properties, aluminum has become more important than many materials known since ancient times, such as wood, copper, iron and steel. Since the second half of the 19th century, aluminum has been a very young metal produced on an industrial scale, but today it is used in greater quantities than all non-ferrous metals such as copper and its alloys, lead, tin and zinc combined.

The general properties of aluminum are summarized below:

- Aluminum is light. It weighs only a third of the same volume of steel.

- Aluminum is resistant to weather conditions, foodstuffs and many liquids and gases used in daily life.

- Aluminum has a high reflectivity. With the contribution of its silvery white color to this feature, it has an attractive appearance for both interior and exterior architecture. This beautiful appearance of aluminum can be maintained for a long time with applications such as anodic oxidation (anodizing), lacquers, etc. In many applications, even a natural oxide layer is sufficient.

- The strength of various aluminum alloys is equal to or higher than that of ordinary structural steel.

- Aluminum is an elastic material. Therefore, it is resistant to sudden impacts. In addition, its durability does not decrease at low temperatures. (The strength of steels against sudden impacts decreases at low temperatures).

- Aluminum is an easy metal to process. It can be made into foil or wire with a thickness of less than I/100 mm.

- Aluminum conducts heat and electricity as well as copper.

As you know, aluminum is not a very suitable material for thermal insulation. However, the aluminum profiles used in aluminum windows are thermally partitioned profiles. In thermally segmented, that is, thermally insulated aluminum profiles, the aluminum profile parts in contact with the interior and exterior are separated from each other by plastic barriers.

Although thermally insulated profiles started to be produced in the world in the early 1970s, window applications in Turkey in the early years without insulation and/or missing details and complements caused misperceptions such as “aluminum conducts heat”, “aluminum windows do not have good insulation”, “aluminum windows have sweating problems”. However, especially today, heat-insulated windows have extremely good thermal insulation values and do not look like plastic windows in this regard.

On the other hand, can we say that PVC is a substitute for aluminum? There are many situations where plastic (PVC) joinery cannot be used instead of aluminum. In this respect, the following advantages of aluminum still make aluminum indispensable for architectural projects:

- Aluminum joinery is much more durable, strong, stable and long-lasting than PVC-u joinery. While the lifespan of an aluminum window is shown as 40 years, PVC-u windows need to be replaced every 25 years.

- Unlike vinyl (PVC-u) windows, aluminum windows and doors retain their mechanical properties at low and high temperatures.

- Since aluminum joinery is durable, it allows the use of frames with less visible width. Therefore, you have the chance to make maximum use of daylight.

- While solutions can be produced in limited sizes with wooden and plastic joinery, you can pass wide openings with aluminum windows. Aluminum joinery can be used safely in openings along the floor such as French balconies, shop windows, high-rise buildings where resistance to wind load is very important, and high floors.

- Their resistance against wind loads is strong, they are systems with high moment of inertia.

- 100% recyclable, natural and environmentally friendly. 95% energy saving is achieved in recycling. Does not contain toxic and carcinogenic substances such as lead, mercury etc.

- It does not release toxic gases in a fire. Aluminum windows comply with fire regulations. There is a requirement to use aluminum joinery in the specifications of the Ministry of Public Works, especially in hospital and school projects. In addition to heat resistance, it is an important feature of insulated aluminum windows that they do not emit sparks and toxic gases. PVC-u windows, on the other hand, emit life-threatening acid salt gases and dioxin gases in case of fire.

- Aluminum has a natural anti-corrosion coating. In addition, oxidation (corrosion) is prevented by anodizing (controlled oxidation). It is highly resistant to weather conditions.

- They are much easier to clean and maintain than wood and vinyl (PVC-u) windows. Vinyl windows need to be wiped with alkaline detergents every 6 months to restore their original appearance. Aluminum, on the other hand, can be cleaned even by rain.

- They provide extremely good thermal insulation. You can design a window with Uw = 1.1 W/m2K. Thermal insulation barrier is used for thermal insulation in aluminum windows. Read How to improve thermal insulation in windows. Absolutely no perspiration. Why does perspiration occur?

- There is a wide range of window styles and window opening options.

- It allows the production of sliding doors and windows with wide openings.

- The natural color of metal creates a sense of quality and adds aesthetic appearance to projects. However, when desired, it is also possible to use the surfaces facing the interior and exterior environments in a way to provide integrity in projects by subjecting them to separate surface coating.

Features sought throughout the aluminum joinery system and window

After the correct identification of aluminum profiles, composite aluminum profiles with thermal insulation barrier installation (composite), EPDM wicks and all other complementary parts, another stage is to determine which conditions (air impermeability, waterproofing, resistance to wind load, thermal insulation, noise prevention, etc.) the relationship between these parts in the system is desired to fulfill on the basis of which minimum values. If the joinery systems have already been subjected to these tests, they will be selected accordingly and even the adequacy of the system will be tested on a mockup during the application phase.

Criteria to be followed during Aluminum Joinery Installation

- In order to prevent the sashes from sagging, wedging principles should be followed when installing the glass.

- Aluminum profiles should have protective tapes on their visible surfaces and should be protected until after assembly.

- The wicks must be made of EPDM material and must be glued at the corners. Special adhesives are recommended for EPDM.

- Water drainage holes must be drilled and covers must be fitted.

- Corner wedges should be of the same alloy as the aluminum profiles, placed by applying epoxy and pressed with a corner press.

Window and Door Details

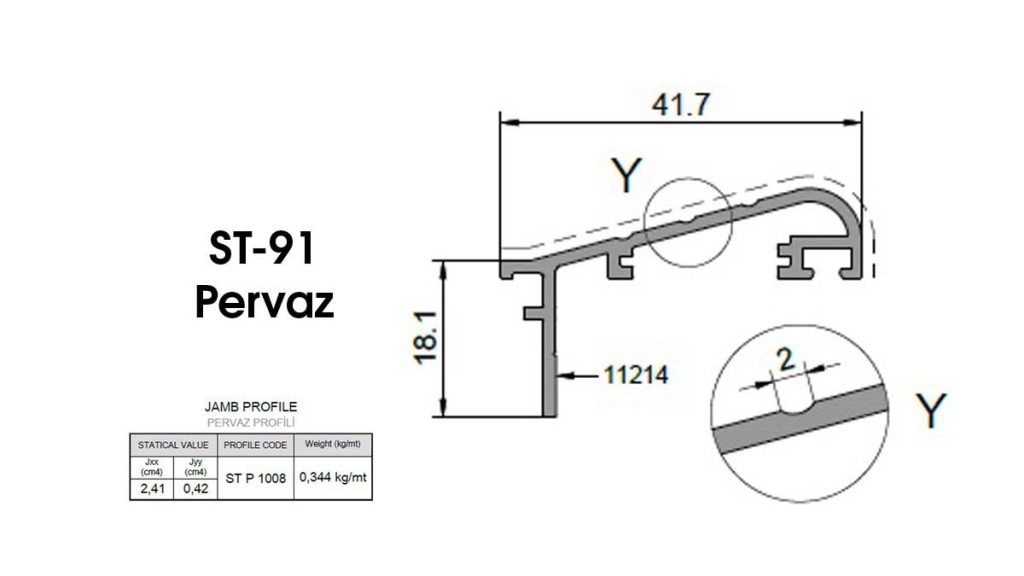

- Detay Aluminum Profiles

- Solid Color Catalog

- Wooden Pattern Catalog

Detail profiles do not have to be used in aluminum door and window systems. Detail aluminum profiles; It is preferred by the Aluminum window practitioner in order to solve possible problems in the application of aluminum doors and windows or to meet the demands of the end consumer.

It can be used to organize the architectural appearance of the window or to improve its performance, as well as to solve an existing application difficulty or problem.

Another advantage of detail profiles is that they are not only used in aluminum door and window systems. They are used in different sectors such as construction, agriculture sector (greenhouse cultivation etc.), pharmaceutical and chemical industry.

Detail profiles provide ease of use in different areas due to their corrosion resistance, long life and superior insulation values.

Main Profiles:

Solid Color Ral Chart

| RAL 1000 | RAL 1001 | RAL 1002 | RAL 1003 | RAL 1004 |

| RAL 1005 | RAL 1006 | RAL 1007 | RAL 1011 | RAL 1012 |

| RAL 1013 | RAL 1014 | RAL 1015 | RAL 1016 | RAL 1017 |

| RAL 1018 | RAL 1019 | RAL 1020 | RAL 1021 | RAL 1023 |

| RAL 1024 | RAL 1027 | RAL 1028 | RAL 1032 | RAL 1033 |

| RAL 1034 | RAL 1037 | RAL 2000 | RAL 2001 | RAL 2002 |

| RAL 2003 | RAL 2004 | RAL 2008 | RAL 2009 | RAL 2010 |

| RAL 2011 | RAL 2012 | RAL 3000 | RAL 3001 | RAL 3002 |

| RAL 3003 | RAL 3004 | RAL 3005 | RAL 3007 | RAL 3009 |

| RAL 3011 | RAL 3012 | RAL 3013 | RAL 3014 | RAL 3015 |

| RAL 3016 | RAL 3017 | RAL 3018 | RAL 3020 | RAL 3022 |

| RAL 3027 | RAL 3031 | RAL 4001 | RAL 4002 | RAL 4003 |

| RAL 4004 | RAL 4005 | RAL 4006 | RAL 4007 | RAL 4008 |

| RAL 4009 | RAL 4010 | RAL 5000 | RAL 5001 | RAL 5002 |

| RAL 5003 | RAL 5004 | RAL 5005 | RAL 5007 | RAL 5008 |

| RAL 5009 | RAL 5010 | RAL 5011 | RAL 5012 | RAL 5013 |

| RAL 5014 | RAL 5015 | RAL 5017 | RAL 5018 | RAL 5019 |

| RAL 5020 | RAL 5021 | RAL 5022 | RAL 5023 | RAL 5024 |

| RAL 6000 | RAL 6001 | RAL 6002 | RAL 6003 | RAL 6004 |

| RAL 6005 | RAL 6006 | RAL 6007 | RAL 6008 | RAL 6009 |

| RAL 6010 | RAL 6011 | RAL 6012 | RAL 6013 | RAL 6014 |

| RAL 6015 | RAL 6016 | RAL 6017 | RAL 6018 | RAL 6019 |

| RAL 6020 | RAL 6021 | RAL 6022 | RAL 6024 | RAL 6025 |

| RAL 6026 | RAL 6027 | RAL 6028 | RAL 6029 | RAL 6032 |

| RAL 6033 | RAL 6034 | RAL 7000 | RAL 7001 | RAL 7002 |

| RAL 7003 | RAL 7004 | RAL 7005 | RAL 7006 | RAL 7008 |

| RAL 7009 | RAL 7010 | RAL 7011 | RAL 7012 | RAL 7013 |

| RAL 7015 | RAL 7016 | RAL 7021 | RAL 7022 | RAL 7023 |

| RAL 7024 | RAL 7026 | RAL 7030 | RAL 7031 | RAL 7032 |

| RAL 7033 | RAL 7034 | RAL 7035 | RAL 7036 | RAL 7037 |

| RAL 7038 | RAL 7039 | RAL 7040 | RAL 7042 | RAL 7043 |

| RAL 7044 | RAL 7045 | RAL 7046 | RAL 7047 | RAL 8000 |

| RAL 8001 | RAL 8002 | RAL 8003 | RAL 8004 | RAL 8007 |

| RAL 8008 | RAL 8011 | RAL 8012 | RAL 8014 | RAL 8015 |

| RAL 8016 | RAL 8017 | RAL 8019 | RAL 8022 | RAL 8023 |

| RAL 8024 | RAL 8025 | RAL 8028 | RAL 9001 | RAL 9002 |

| RAL 9003 | RAL 9004 | RAL 9005 | RAL 9006 | RAL 9007 |

| RAL 9010 | RAL 9011 | RAL 9016 | RAL 9017 | RAL 9018 |

Color Differences occur due to the Monitor and Peripherals of the products displayed in the Computer Environment, please request a color chart for more accurate color and pattern determination.

Main Profiles:

Color Differences occur due to the Monitor and Peripherals of the products displayed in the Computer Environment, please request a color chart for more accurate color and pattern determination.